Assembly Enquiry

Instant Quote

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Our fully automated SMT line includes 9 inspection processes to ensure the highest quality for you.

Prevent process defects caused by material issues during production and avoid efficiency losses due to non-compliant quality of refurbished materials.

Detect solder paste printing defects to prevent them from entering the next process.

Check for any errors, omissions, or defects in the PCBs to prevent them from flowing into the next process.

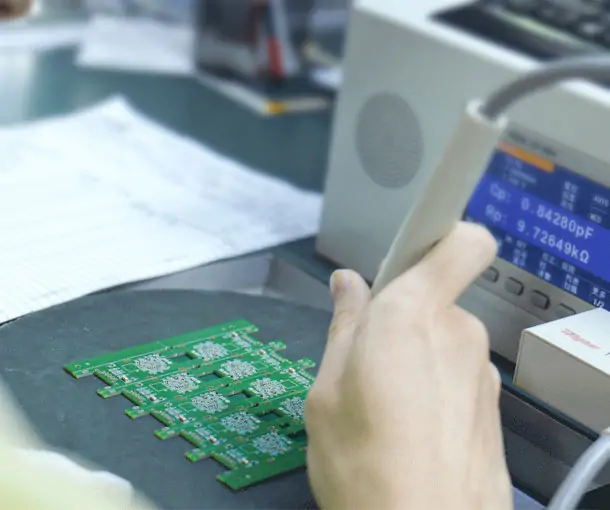

Verify the accuracy of the placement process on the production line and ensure each component's parameters are within standard limits.

Conduct random inspections of all production processes to ensure compliance with the work instructions.

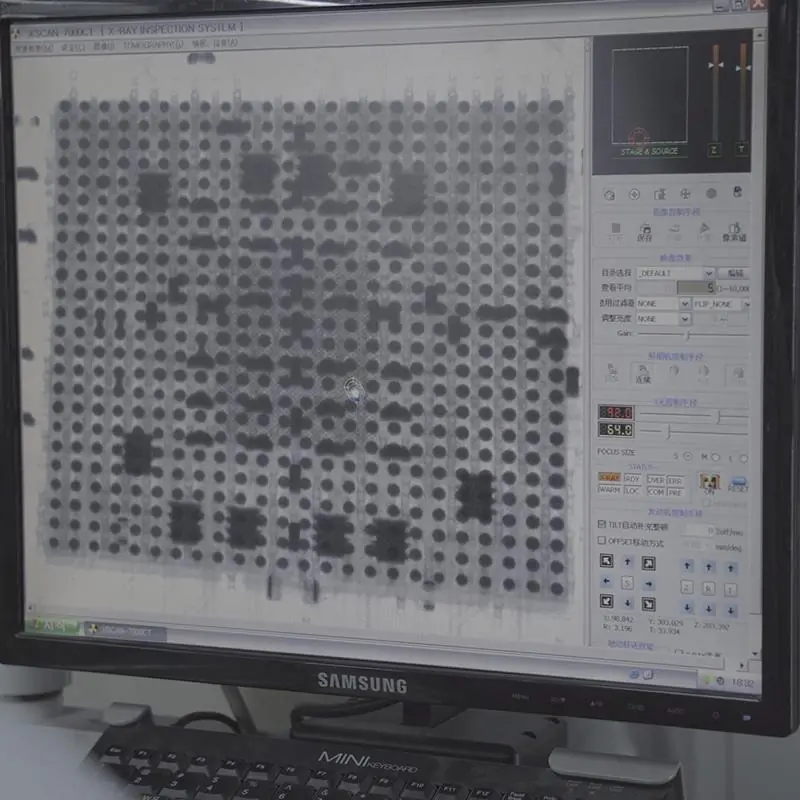

Inspect the solder joints of components that are invisible to the naked eye to ensure the reliability of BGA solder balls.

Inspect finished PCBA according to the IPC-610 inspection standard.

Conduct strict inspections before shipment, along with barcode scanning verification, to prevent defective products from being shipped.

Strict inspections are carried out before shipment, with scanning and verification to ensure no defective products are shipped.

Submit your Gerber files, BOM (Bill of Materials), and any project-specific requirements to us.

Our engineering team will review your files and verify technical specifications

Get a detailed quote including pricing, lead time, and shipping options.

Review and confirm your order details, then proceed with payment to start production.

Established in Shenzhen, China, in 2011, PCBasic boasts more than 15 years of hard work and innovation in the field of PCB & PCBA manufacturing. The considerable expertise in printed circuit boards and decades of industrial experience grant PCBasic the confidence and strength to overcome challenges and deliver the best-in-class PCB & PCBA solutions, making it one of the leading PCB & PCBA manufacturers around the globe.

Learn MoreStrictly comply with ISO9001, IATF16949, and ISO13485 standards.

Rapid delivery for small batch products--within 24 hours at the fastest.

PCBasic is equipped with a professional R&D team and possesses a self-invented intelligent production management system.

No MOQ, even can get PCBs free!

With multiple supply chains, PCBasic can offer the best quality at the most competitive prices.

PCBasic guarantees a full refund in case of quality problems.

Serves more than 100 countries around the world

Has over 120,000 global customers in PCB prototype assembly service

Handles 1000+ pieces of PCB design and layout order documents every day

Boasts 96.15% on-time delivery in PCBA service

Thanks to 15+ years of effort and innovation in electronics, PCBasic has become one of the leading PCB & PCBA manufacturers in Shenzhen, China.

As a professional PCB & PCBA manufacturer in China, we provide online PCB design and manufacturing services, along with a variety of assembly solutions.

Explore the comprehensive guide to PIC Microcontrollers, covering architecture, families, programming, and applications—from 8-bit basics to powerful 32-bit solutions.

Learn the benefits of using PTFE (Teflon) PCBs in high-frequency applications. PTFE vs FR4: Key Benefits, Manufacturing Processes, and Top Suppliers like Rogers PCB 4. Understand when to select PTFE PCB material for RF, aerospace, and 5G designs.

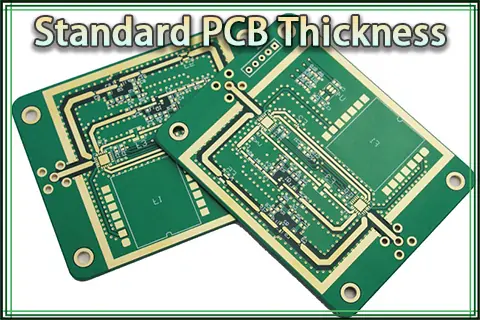

A PCB thickness measurement is among the most important measurements in electronic manufacturing. You know, it affects device performance and manufacturing costs. Let's learn what PCB thickness really is.

More Than 100+ Patent Certificates

Upload Files

Upload Files

Technical Review

Technical Review

Receive Quote

Receive Quote

Confirm Order

Confirm Order