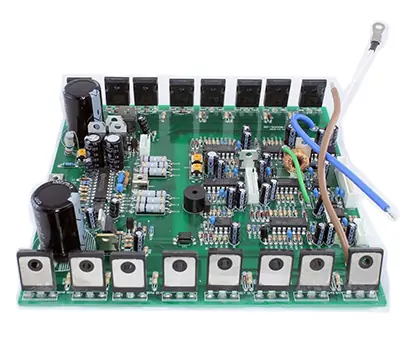

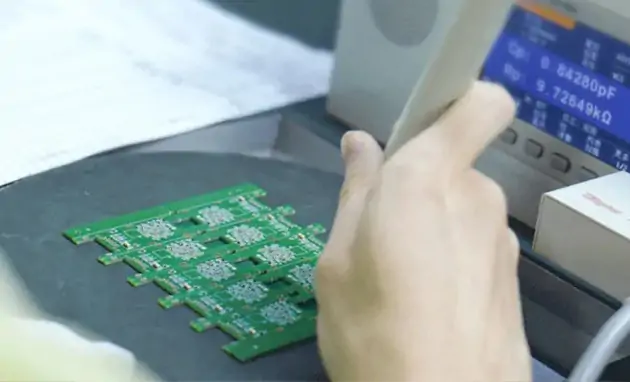

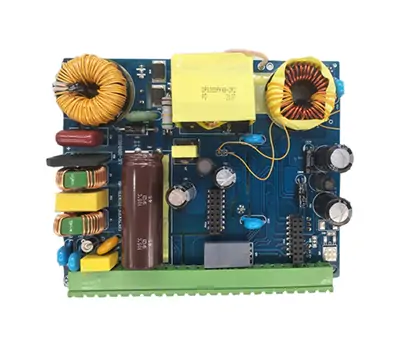

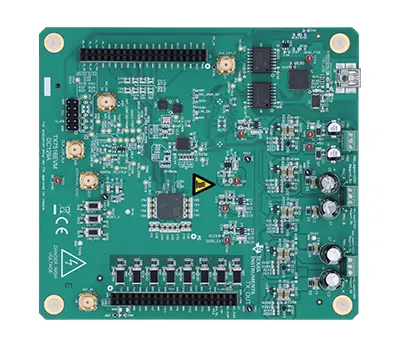

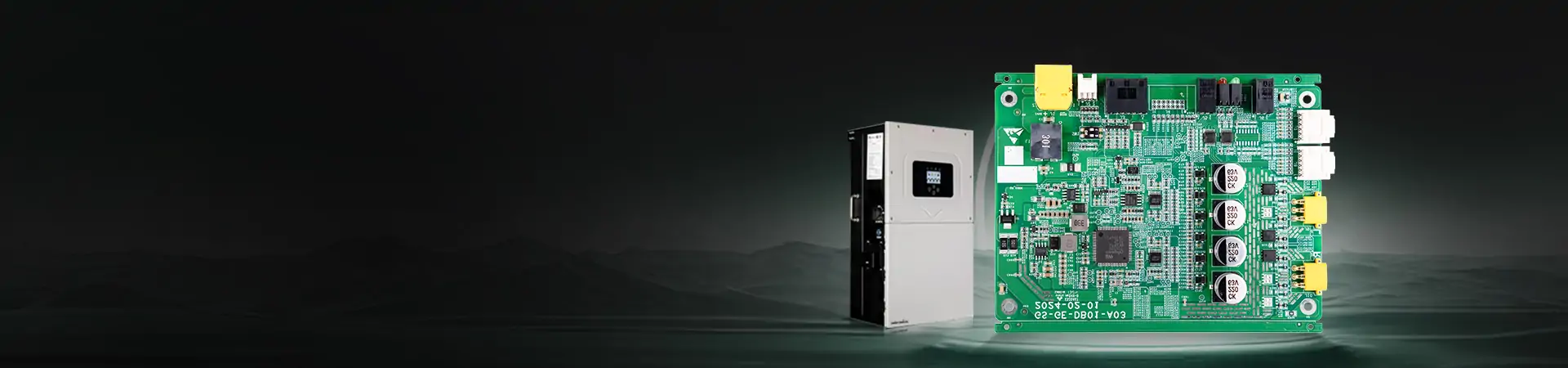

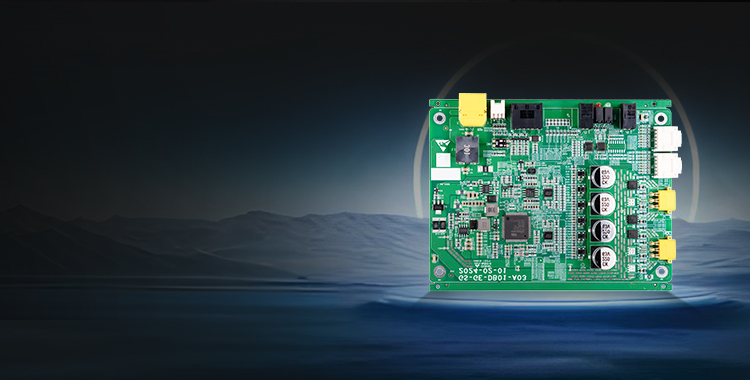

Energy Storage PCB Assembly

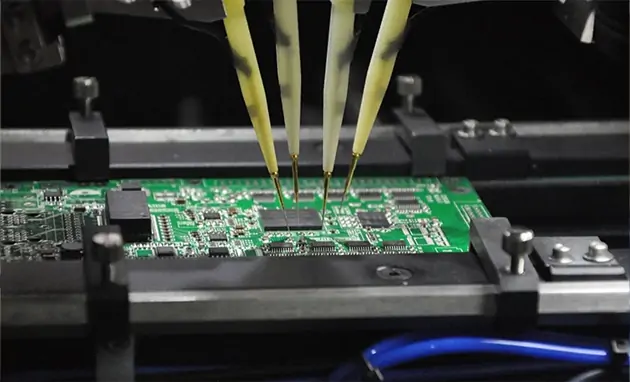

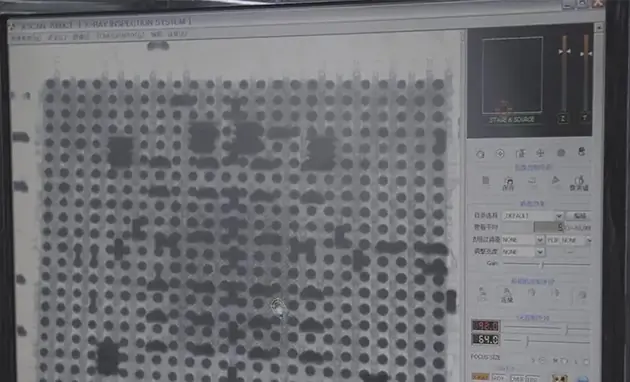

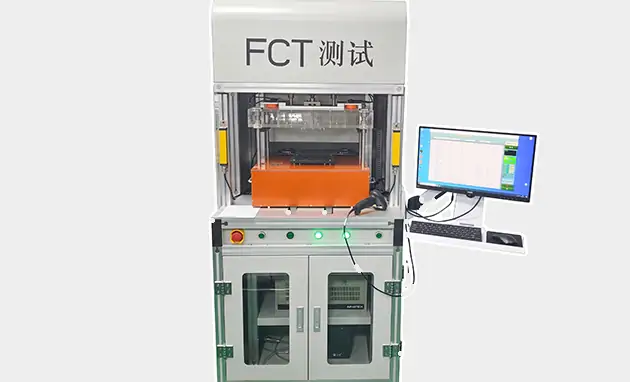

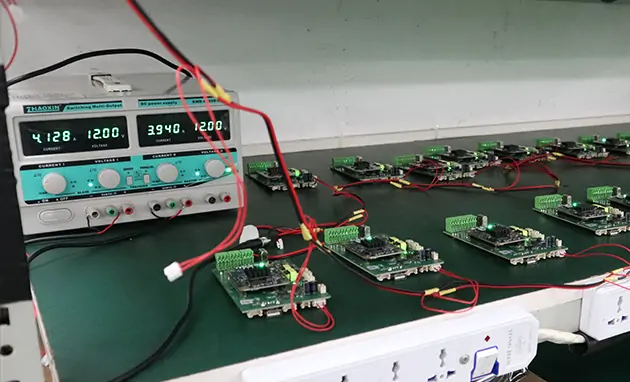

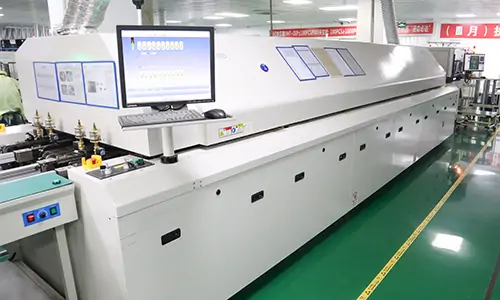

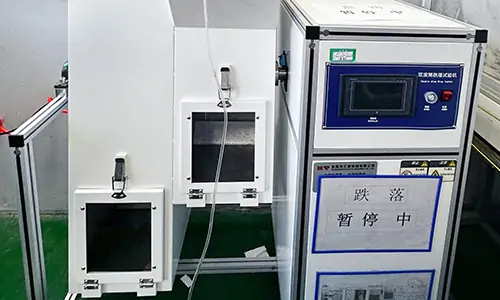

PCBasic delivers high-precision rigid-flex PCB/PCBA solutions for energy storage PCBs, supporting complex designs while ensuring superior quality, rapid delivery, and cost competitiveness.

15+ years of professional experience and continuous investment in PCBA technology

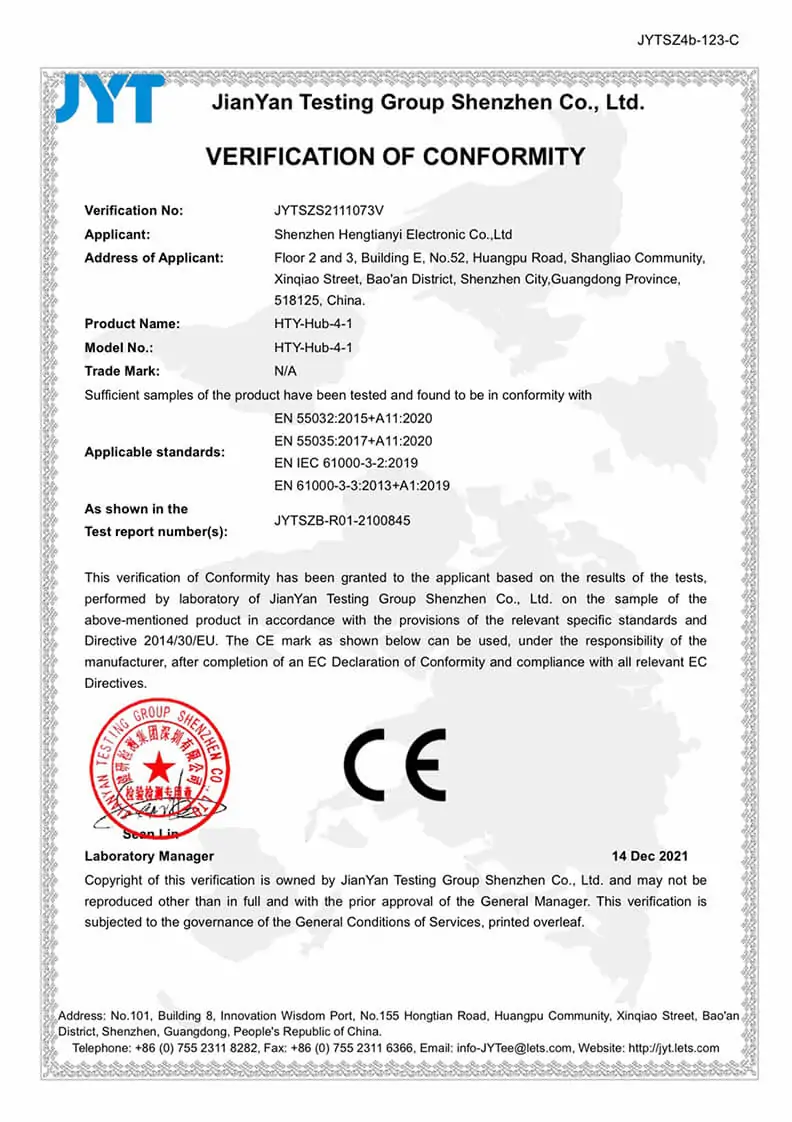

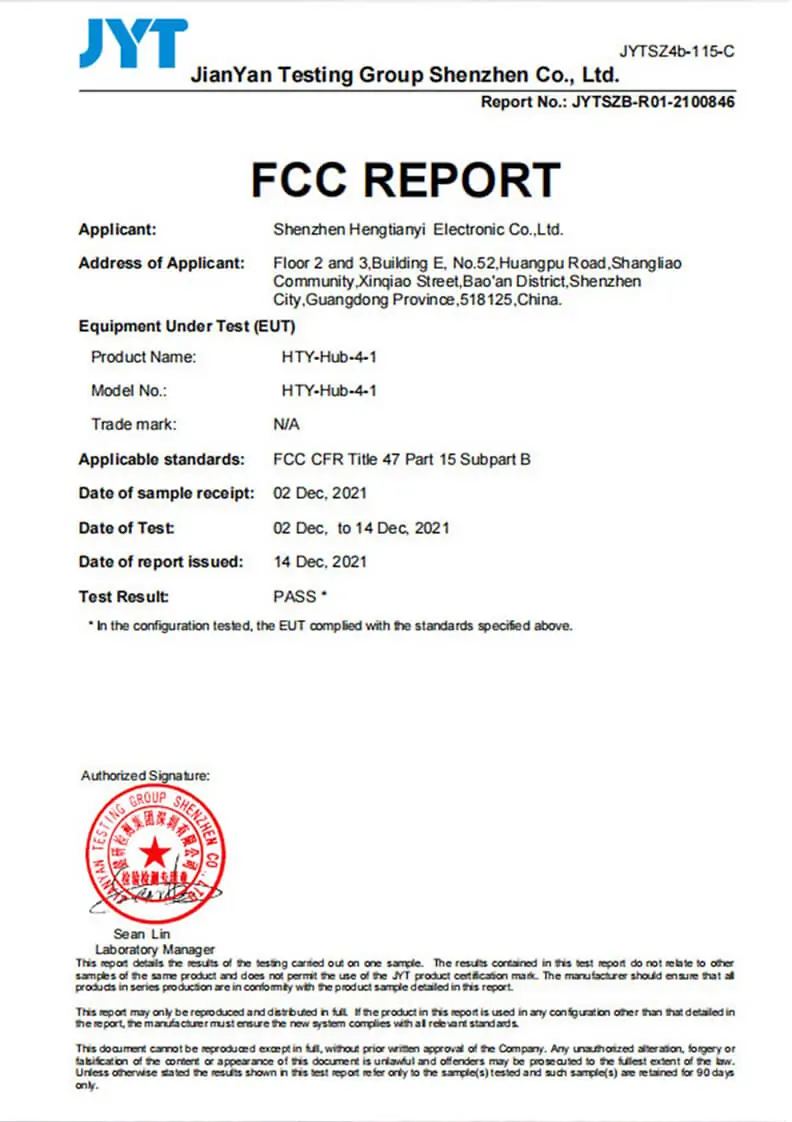

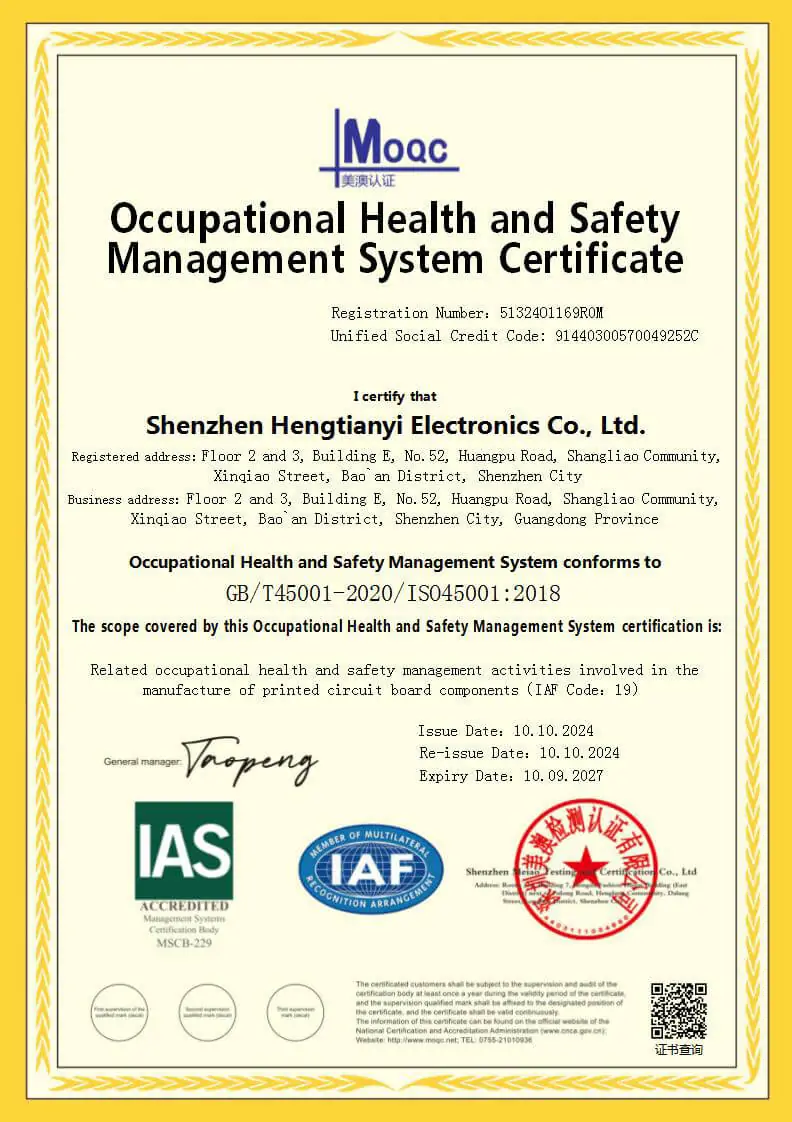

Certified with ISO 9001, ISO 13485, ISO 14001, and ISO 45001

24-hour fast delivery capability, supported by a team of over 200 skilled professionals.

Energy Storage PCB Assembly

PCBasic delivers high-precisionrigid-flex

PCB/PCBA solutions for energy storage PCBs,

supporting

complex designs while

ensuring superior quality, rapid delivery,

and cost competitiveness.