Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What Does SMT Stand For In PCBA Manufacturing?

With the development of science and technology, the development of various electronic equipment is also changing with each passing day, and the requirements for the circuit board that plays a key role in the equipment are getting higher and higher. People ask for smaller and more accurate devices and PCBA manufacturers rely on advanced technology to deliver high-performance, reliable products.

At the same time, the circuit board assembly technology is becoming more and more powerful. In addition to the traditional through-hole assembly technology (THT), surface mount technology (SMT) has contributes greatly to the PCBA manufacturing. But what exactly does SMT stand for in PCBA manufacturing? In this article, we will explore the meaning of PCBA and SMT, gain insight into the steps of SMT PCB assembly, and understand how SMT production lines ensure the efficiency and precision of modern electronics.

PCBA, full name Printed Circuit Board Assembly, refers to the process of assembling electronic components on a printed circuit board (PCB). In short, PCBA is the key step from design to function realization of electronic products, through the precise assembly of components on the PCB, so that the circuit board has a complete function. It is the core of modern electronic devices, and almost all electronic products cannot be separated from PCBA support.

The PCBA manufacturing process consists of several steps. From a bare board to a fully functional circuit board, PCB assembly is the core. During the process, through-hole assembly technology and surface mount technology are commonly used. They two have their own advantages and characteristics, playing a significant impact on the quality control of the circuit board.

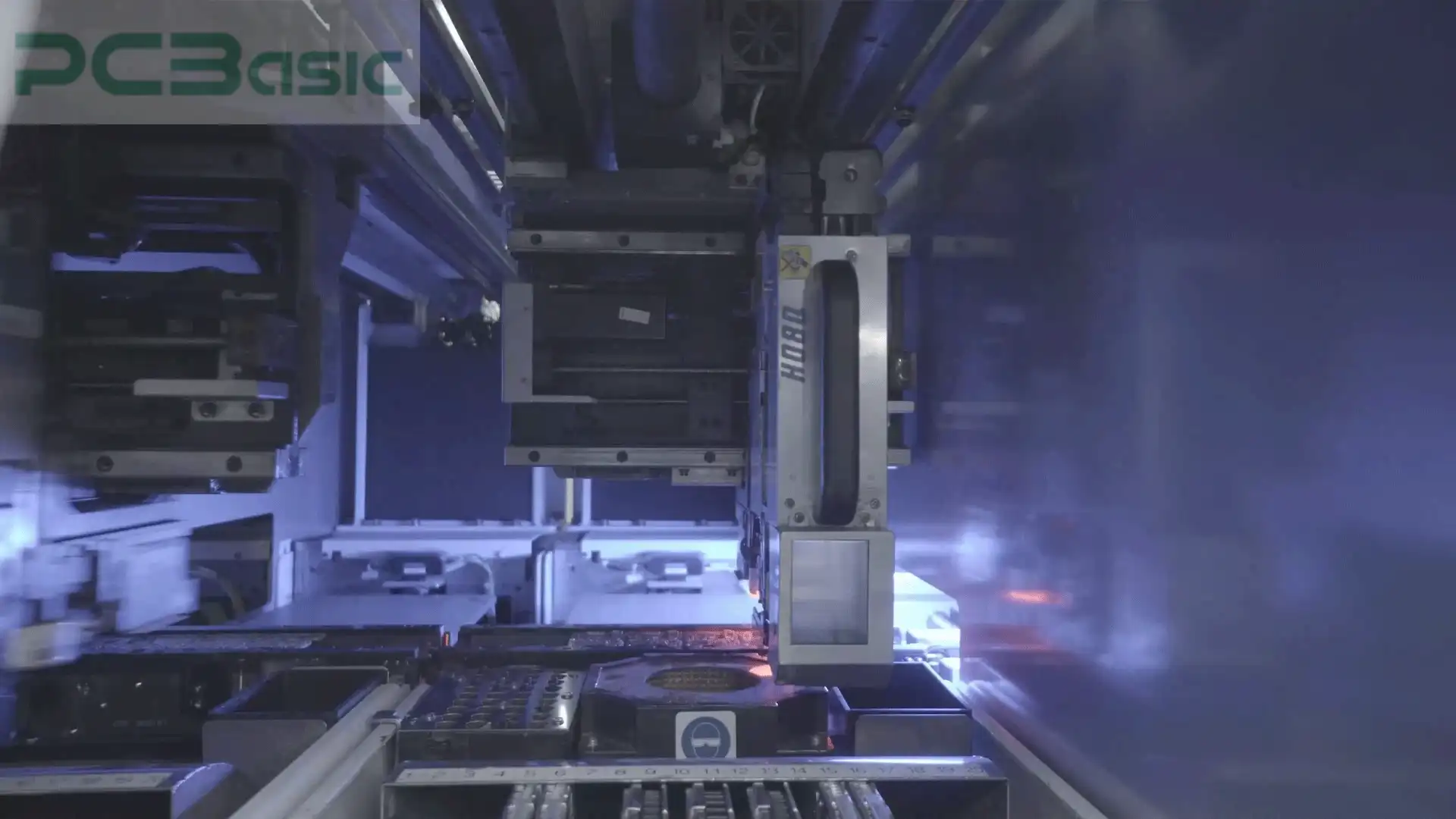

SMT PCB assembly refers to an assembly method that installs electronic components directly on the circuit board through surface mount technology. The entire assembly process is usually completed on an advanced SMT production line, including multiple steps such as solder paste printing, component mounting, reflow soldering and automatic inspection.

Compared with traditional through-hole assembly technology, efficient SMT production lines can assemble smaller and lighter components, allowing board design more compact and complex. At the same time, this highly automated technology can accurately place components on the PCB and firmly connect them through a high-precision soldering process, greatly improving the accuracy and speed of product production.

For a reliable PCBA manufacturer, having an efficient SMT production line is the key to meeting the market demand for high-quality electronics. From consumer electronics to industrial equipment, SMT PCB assembly plays an integral role in ensuring product reliability and technological advancement. Whether you’re developing prototypes or scaling up for mass production, an efficient SMT production line ensures precision, speed, and consistent quality.

On a highly automated SMT production line, from solder paste coating to component mounting, reflow soldering to inspection and testing, each step of the SMT PCB assembly process reflects the combination of high technology and fine technology. These interlocking steps ensure the quality, reliability and functionality of each PCB and each step lays the foundation for achieving high-quality electronics.

The first step in SMT PCBA is to apply solder paste to a specified area on the PCB. Through the stencil and automatic stencil printer, the solder paste is precisely applied to the pad to prepare the components for installation. Precision in solder paste application is critical, as it directly impacts the reliability of component soldering and the performance of electrical connections, serving as the foundation of the entire assembly process.

After the solder paste application is complete, the automatic pick-and-place machine begins component placement. According to the PCB design layout, the machine positions various electronic components, such as resistors, capacitors and diodes, onto their designated locations rapidly and accurately. A well-configured SMT production line ensures high-speed, high-precision placement, guaranteeing both efficiency and quality.

After component placement, the PCB enters a reflow oven, where the solder paste is melted in a controlled high-temperature environment to create reliable electrical connections between the components and the PCB. The reflow oven allows all components to be soldered simultaneously, significantly improving efficiency while ensuring the quality of the solder joints.

After soldering is complete, the assembled PCB undergoes rigorous inspections to ensure that the quality of each board meets the design requirements. SMT production lines commonly use Automated Optical Inspection (AOI) and X-ray inspection to evaluate the soldering quality of the circuit boards.

For some PCBs requiring additional assembly, such as the addition of connectors or larger components, final testing is conducted after all assembly steps are completed. This includes in-circuit testing and functional testing to verify whether their performance meets the design specifications.

In the field of PCBA manufacturing, partnering with a reliable PCBA manufacturer like PCBasic offers unparalleled advantages. With years of industry experience and state-of-the-art production facilities, PCBasic provides high-quality SMT PCB assembly services tailored to meet the needs of various industries.

One of the key highlights of working with PCBasic is their advanced 8 SMT production lines. Each SMT line is equipped with cutting-edge technology, efficiently handling complex SMT processes such as solder paste application, precise component placement, and reflow soldering. These SMT production lines are not only fast and efficient but also ensure the precision and consistency of PCB SMT assembly, delivering high-quality results for every project.

By choosing PCBasic, you gain access to advanced SMT assembly capabilities, 8 efficient SMT production lines, and the full support of a professional team. Whether for prototype development or large-scale production, PCBasic’s comprehensive services in PCBA manufacturing guarantee that your electronic products stand out in today’s competitive market.

SMT plays a vital role in PCBA manufacturing, providing efficient and precise assembly technology for modern electronic devices. From solder paste application to component placement, reflow soldering, and testing, every step reflects the seamless integration of advanced technology and precision engineering. With 8 state-of-the-art SMT production lines and extensive industry experience, PCBasic delivers unmatched SMT PCB assembly services. Whether for prototype development or mass production, PCBasic ensures high-quality, high-performance electronic products, helping clients stand out in today’s competitive market.

Ready to bring your electronics project to life? Explore the power of SMT assembly and collaborate with a trusted PCBA manufacturer PCBasic to achieve your goals!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.