Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Mastering PCBA Design: A Comprehensive Guide

In today’s technology-driven world, PCBA design (Printed Circuit Board Assembly Design) plays a critical role in powering modern electronic devices. From smartphones to industrial machinery, the success of these products relies on a robust and efficient circuit board design. Whether you're a professional engineer or a hobbyist working on a DIY circuit board, understanding the fundamentals of PCBA design is essential to creating reliable and high-performance devices.

This guide explores the process of PCBA board design, from creating a PCB schematic to selecting the right materials, such as FR4 electronic PCB/PCBA design, and leveraging professional PCBA design services. By the end of this article, you will have a solid understanding of what goes into designing a great circuit board, and why choosing the right design partner matters.

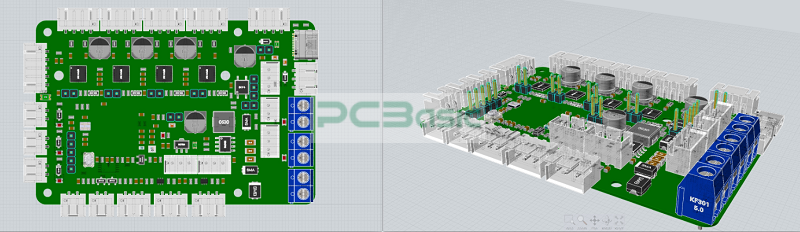

PCBA design refers to the process of creating a printed circuit board assembly that integrates electronic components onto a circuit board. It involves two major aspects:

1. Designing the PCB schematic: Laying out the electronic connections between components.

2. Assembling the PCB: Attaching components such as resistors, capacitors, and ICs to create a functional device.

· Optimizes Performance: A well-executed PCBA board design ensures minimal interference, reduced noise, and enhanced signal integrity, resulting in devices that operate smoothly.

· Facilitates Manufacturability: Professional PCBA design services streamline production, reduce errors, and improve efficiency during manufacturing.

· Enables Customization: From consumer gadgets to industrial automation systems, PCB assembly/PCBA design offers tailored solutions for diverse applications.

The PCB schematic serves as the blueprint for your circuit board, outlining how components will be connected. A strong schematic design ensures the success of the entire project. Key steps include:

· Defining the electrical pathways between components.

· Using specialized design software to create a clear, logical layout.

· Verifying the schematic to identify and fix errors before moving to the next phase.

Material selection directly impacts the durability and performance of your PCBA board design. FR4 electronic PCB/PCBA design is a widely used material due to its excellent insulation, mechanical strength, and cost-effectiveness. For high-frequency or specialized applications, other materials like ceramic or Rogers laminates may be chosen.

Once the schematic is finalized, the design is translated into a physical layout. Important considerations include:

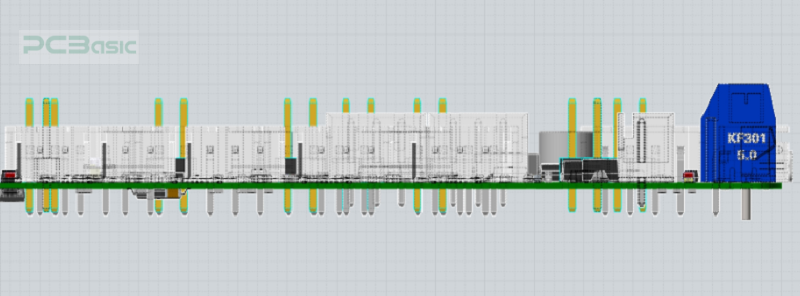

· Trace Width and Spacing: Ensuring proper spacing for signal integrity and heat dissipation.

· Component Placement: Strategically positioning components to minimize interference.

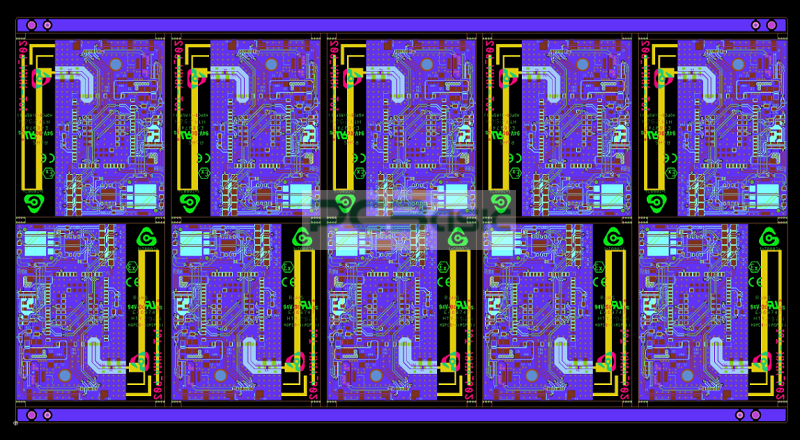

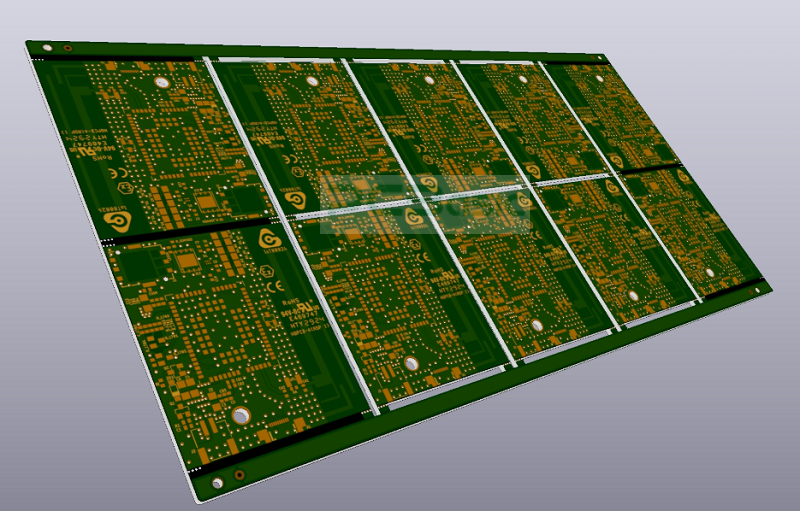

· Layer Stacking: Using multiple layers for routing, grounding, and thermal management.

Before mass production, building and testing a prototype is critical to verify the design's functionality. This stage helps identify potential issues, especially for DIY circuit boards or new designs, ensuring the final product meets quality and performance standards.

Even seasoned designers face challenges when working on circuit boards:

· Signal Integrity Issues: Poor routing can result in noise and reduced performance.

· Thermal Management: Devices with high power output need effective heat dissipation to prevent overheating.

· Manufacturing Constraints: Designs must align with the capabilities of PCB assembly/PCBA design processes to ensure efficient production.

Collaborating with experienced PCBA design services providers like PCBasic helps overcome these challenges and ensures your design meets all technical and functional requirements.

PCBA board design is the backbone of various industries, powering devices that shape our daily lives. Key applications include:

From smartphones and laptops to wearables and gaming consoles, circuit boards designed with PCB assembly/PCBA design processes enable seamless performance in compact devices.

Modern vehicles rely heavily on FR4 electronic PCB/PCBA designs for components like Advanced Driver Assistance Systems (ADAS), engine control units, and infotainment systems.

Internet of Things (IoT) devices require energy-efficient and compact PCBA board designs to support wireless connectivity and real-time data processing.

Hobbyists and makers use PCBA design to create custom projects, from smart home devices to personalized keyboards, showcasing the versatility of circuit boards.

Robust PCBA board designs are essential for powering machines and systems in factories, ensuring efficiency and reliability in demanding environments.

Selecting the right PCBA design services provider is critical to the success of your project. Key factors to consider include:

1. Expertise: Choose a provider experienced in handling complex PCB assembly/PCBA design projects across various industries.

2. Prototyping Capabilities: Ensure the provider can deliver prototypes quickly to facilitate testing and improvements.

3. Quality Assurance: Reliable providers conduct thorough testing to ensure each circuit board meets industry standards for safety and performance.

PCBasic stands out as a leader in PCBA board design services. With years of experience, advanced manufacturing capabilities, and a focus on customer satisfaction, PCBasic delivers tailored solutions that exceed expectations.

The field of PCBA design is evolving rapidly, driven by technological advancements and changing market demands:

HDI technology allows for compact designs with increased functionality, making it ideal for smartphones and wearable devices.

These PCBs offer greater design versatility, particularly for applications requiring bending or folding, such as in medical devices and aerospace systems.

AI-driven tools are revolutionizing PCBA design services by enabling predictive analytics, automated testing, and enhanced design accuracy.

PCBasic is a trusted provider of PCBA design services, offering end-to-end solutions for projects of all scales. Here's why PCBasic is the partner of choice:

· Comprehensive Expertise: From creating precise PCB schematics to delivering high-quality FR4 electronic PCB/PCBA designs, PCBasic ensures every project is a success.

· Cutting-Edge Facilities: With advanced manufacturing tools and experienced professionals, PCBasic guarantees efficient and reliable production.

· Customer-Centric Approach: PCBasic tailors its services to meet the unique requirements of each client, ensuring satisfaction and long-term partnerships.

PCBA design is at the core of modern electronics, enabling the creation of devices that power our lives. From a DIY circuit board to industrial-grade systems, mastering PCBA board design is essential for delivering high-performance, reliable products.

Whether you need help with a PCB schematic, selecting materials for FR4 electronic PCB/PCBA design, or seeking professional PCBA design services, PCBasic is your ideal partner. With a proven track record of excellence, PCBasic transforms ideas into reality. Contact us today to begin your journey toward creating innovative electronic solutions!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.