Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: A Leading Automotive PCB Assembly Manufacturer

Driven by advances in technology, rising safety standards, and the rise of electric and autonomous vehicles, the automotive industry is evolving at an unprecedented pace. Automotive PCB assembly is the core of the electronic system in modern cars, providing physical connectivity and electrical support for key components such as radar, cameras, battery management, navigation and LED lighting. This technology ensures the intelligence and reliability of vehicle functions and is a key link in promoting the development of automotive technology. From advanced driver assistance systems (ADAS) to in-vehicle entertainment systems to powertrains for electric vehicles, automotive PCBS are integral to meeting the automotive industry's stringent requirements for high reliability, precision and durability.

As one of the leading automotive PCB assembly suppliers in China, PCBasic is committed to providing high-quality automotive PCB services and driving innovation in the automotive industry. Next, this article will explore the importance of automotive PCB assembly, the factors to consider when choosing an automotive PCB assembly manufacturer, and PCBasic's automotive PCB assembly.

Automotive PCB assembly refers to the process of installing electronic components (such as resistors, capacitors, chips, etc.) onto a printed circuit board (PCB) designed specifically for automotive applications. This process assembles electronic components onto a circuit board through a process such as surface mount technology (SMT) or through-hole insertion technology (THT) to form a complete electronic circuit module used to support various electronic systems in the car. At the same time, the PCB used must be able to withstand extreme temperatures, vibration and harsh environmental conditions to ensure continuous and stable performance.

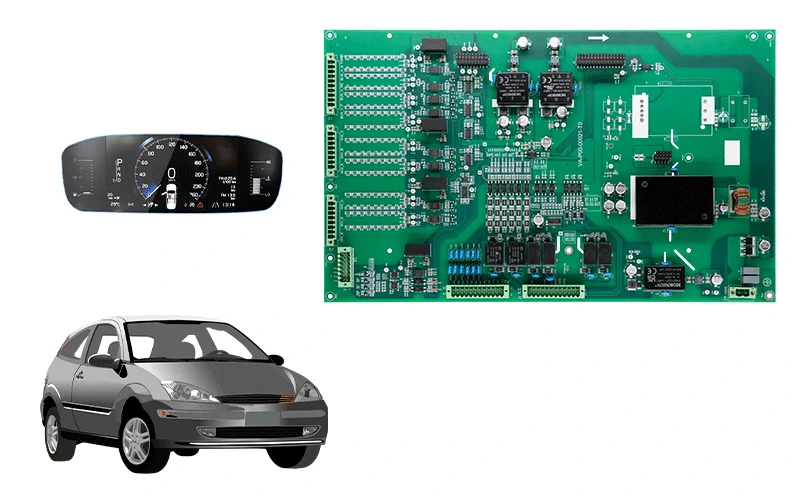

1. ADAS:

Automotive PCB assembly plays a crucial role in ADAS systems, supporting radar, cameras and sensors. These components enable efficient connectivity and precise data processing through automotive PCBs, enhancing vehicle safety and also supporting autonomous driving functions such as lane keeping, emergency braking and blind spot detection.

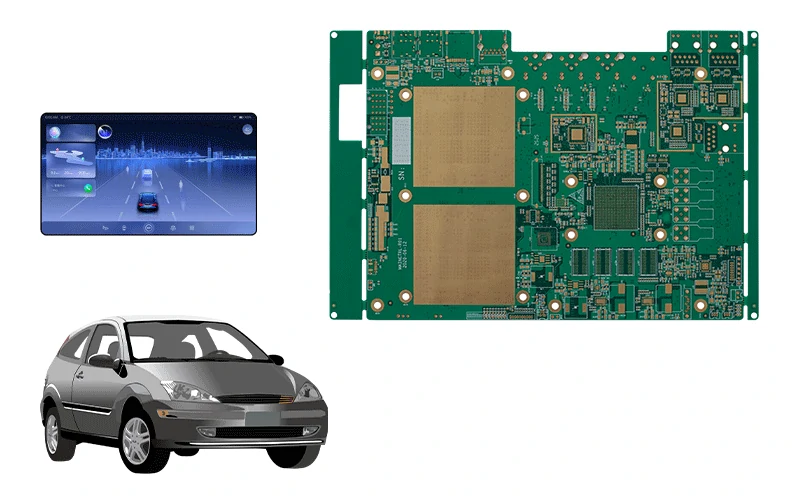

2. Infotainment system:

Infotainment systems in modern vehicles rely on high-quality automotive PCBs to support multimedia capabilities. Automotive PCBs provide basic connectivity for touch screen displays, navigation systems and audio devices, ensuring a smooth user interaction experience. At the same time, advanced automotive PCB design also supports voice control and real-time connection functions.

3. Electric vehicle power system:

The core of an electric vehicle is its powertrain, in which the automotive PCB plays a key role in the battery management system (BMS), motor controller and charging station. Efficient PCB design ensures the stability of power transmission, optimizes the endurance and charging speed of electric vehicles, and helps the development of new energy vehicles.

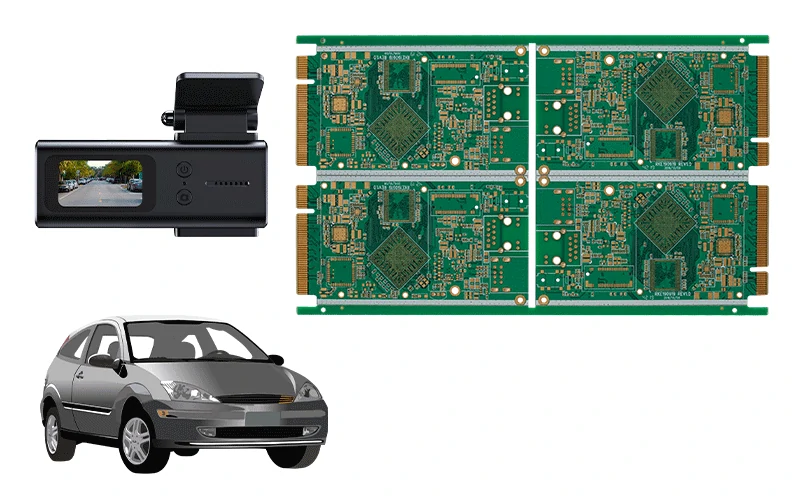

4. Lighting system:

Automotive lighting systems, such as LED headlights, taillights, and in-car ambient lights, rely on automotive PCBA to control brightness, color, and power distribution. The high-precision automotive PCB assembly not only improves the lighting effect, but also extends the service life of the luminaires while reducing power consumption.

These applications demonstrate the indispensable position of automotive PCB assembly in modern vehicles, which supports intelligent functions and reliable performance, driving the continuous advancement of automotive technology. With its wide range of applications, choosing the right automotive PCB assembly manufacturer is critical to ensuring system reliability and compliance with industry standards.

|

Dimension |

Automotive PCB Assembly |

General PCB Assembly |

|

Operating Environment |

Must operate reliably in extreme conditions such as high temperatures, humidity, and vibrations. |

Typically used in stable indoor environments, not required to withstand harsh conditions. |

|

Reliability |

High reliability to ensure uninterrupted operation of critical systems like brakes and safety controls. |

Lower reliability requirements, suitable for non-critical applications such as consumer electronics. |

|

Design Complexity |

Must support complex functions like ADAS, battery management systems, navigation, and infotainment. |

Used for simpler circuits, such as those in appliances and toys. |

|

Miniaturization |

Focuses on compact designs to support high-density wiring within limited spaces, fitting modern automotive trends. |

Less emphasis on miniaturization; high-density wiring is usually not required. |

|

Standard Certifications |

Must comply with stringent industry standards such as IATF 16949, ISO 9001, and AEC-Q200. |

Typically meets basic industry standards like IPC or ISO, with fewer certification requirements. |

|

Material Selection |

Uses high-performance materials (e.g., FR4, ceramic substrates) for durability and heat resistance. |

Uses standard PCB materials (e.g., regular FR4) for cost efficiency. |

|

Manufacturing Difficulty |

Higher complexity due to stringent requirements, demanding advanced equipment and techniques. |

Lower complexity with simpler processes and less reliance on advanced equipment. |

|

Application Scenarios |

Used in critical automotive systems such as ADAS, powertrain systems, lighting, and infotainment. |

Mainly used in consumer electronics, household appliances, and industrial equipment. |

|

Cost |

Higher manufacturing costs due to advanced materials and rigorous standards. |

Lower manufacturing costs, suitable for large-scale, low-cost production. |

Experienced manufacturers are able to better understand the stringent requirements of the automotive industry such as high reliability and durability; Able to handle complex circuit board design and high volume production tasks. Therefore, it is preferred to choose suppliers with many years of experience in the field of automotive PCB.

A good automotive PCB assembly manufacturer of course needs to have the following technical capabilities:

There are advanced equipment: such as high-precision SMT production line, AOI automatic optical inspection, X-ray test equipment, flying probe test equipment, reflow welding equipment and so on.

Customized services: Support the production of complex designs such as multi-layer boards, HDI boards and flexible boards.

Good thermal management: for the car, its circuit board (that is, automotive PCB) must be able to handle the heat dissipation requirements of high-power equipment, so as to ensure the stable operation of the circuit board in harsh environments.

The automotive PCB assembly manufacturers should have internationally certified standards, such as:

|

Standard |

IATF 16949 |

AEC-Q200 |

|

Full Name |

International Automotive Task Force 16949 |

Automotive Electronics Council-Q200 |

|

Applicable Industry |

Automotive Industry |

Automotive electronics industry |

|

Core Content |

Quality management system standard for the automotive industry, covering production, design, and related services |

Reliability testing and certification standard for automotive-grade passive components |

|

Objective |

Enhance the quality of the automotive supply chain, reduce waste, and improve efficiency |

Ensure high reliability and durability of automotive electronic components |

|

Key Features |

Includes ISO 9001 requirements Emphasizes error-proofing and process control Supplier performance evaluation Continuous improvement |

Provides guidelines for component reliability testing Specifies mechanical, environmental, and lifespan tests |

4. Delivery time and logistics support

Automotive PCB manufacturers should be able to turn around fast (short lead times can help customers get to market quickly), and should also have global logistics support (can provide efficient supply chain management services to ensure that products are delivered on time).

5. Customer service and technical support

Choose a manufacturer that offers full support, including:

· Technical consulting: to assist customers to optimize the design.

· After-sales service: quickly respond to problems and provide solutions.

·Continuous improvement: Continuously improve customer satisfaction through innovative technologies and optimized processes.

Whether you need prototype development or mass production, PCBasic can be your reliable partner with superior technology and attentive service. Choose PCBasic for your automotive PCB project! Take a look at PCBasic's automotive PCB assembly!

PCBasic's PCB assembly service has more than 15 years of experience, and with these years of experience, PCBasic has developed into a leading automotive PCB assembly manufacturer in China, able to provide comprehensive solutions to customers around the world.

Advanced manufacturing facilities:

Equipped with 9 SMT production lines, including high-speed JUKI, Panasonic equipment, flying probe testing machine, reflow welding machine, wave soldering machine, etc., can accurately handle complex automotive PCB assembly projects.

Quality-focused processes:

PCBasic is certified to the relevant industry standards to ensure that every PCB automotive product meets industry benchmarks for reliability and safety.

Full service:

From automotive PCB design to assembly and testing, we offer end-to-end solutions that meet our customers' needs.

Scale flexibility:

Whether prototyping or mass production, PCBasic, as a wholesale automotive PCB assembly manufacturer, consistently delivers high quality.

Global business coverage:

As a top Chinese automotive PCB assembly supplier, we provide seamless logistics support to ensure timely delivery of products to customers around the world.

In the rapidly evolving automotive industry, partnering with the right automotive PCB assembly manufacturer is critical to delivering reliable, high-performance solutions. As a leading automotive PCB assembly supplier in China, PCBasic combines advanced manufacturing capabilities, stringent quality standards and unmatched customer support to provide customers with the best automotive PCB services.

Whether you need test samples or high volume production for the global market, PCBasic is a trusted manufacturer of wholesale automotive PCB assemblies to help you stay ahead of the competition in the automotive sector. Contact us today to turn your automotive PCB assembly needs into reality!

Assembly Enquiry

Instant Quote