Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PIC Microcontrollers: Architecture, Features, and Applications

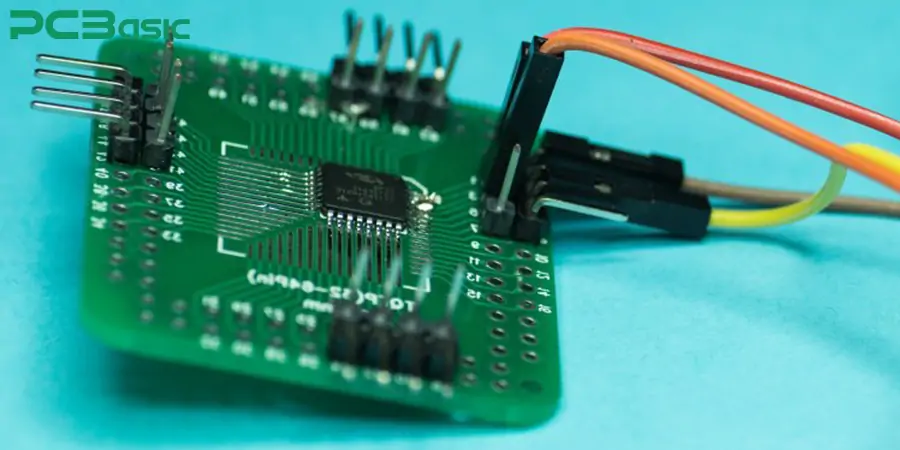

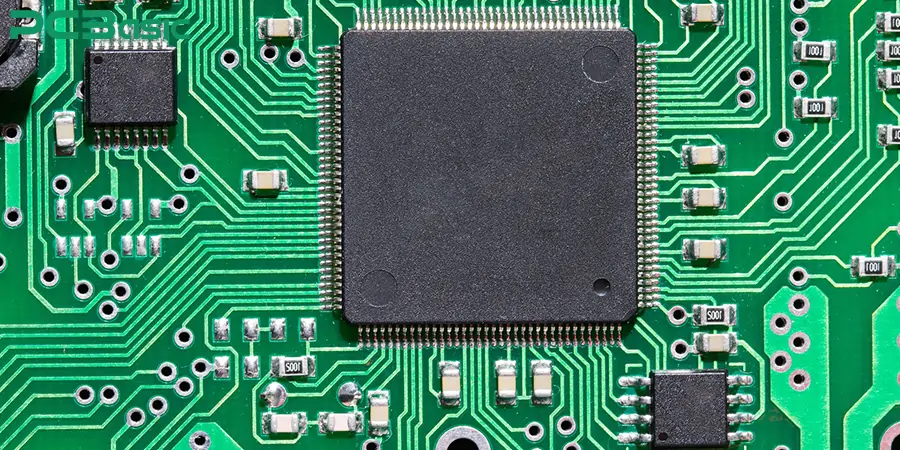

Consider a microcontroller in an embedded system as the central processing unit which manages multiple electronic applications. The microcontroller market has different offerings. However, PIC microcontrollers are known for their simplicity and ease of use, proven dependability, and scalability. They have made life easy in many products like household appliances, cars, industrial equipment, and educational tools.

The various development tools available with microchips along with the documentation, community, and ongoing assistance help strengthen the relationship with PIC microcontrollers. These materials allow resources to be tailored for every level of a programmer, whether they are new to the world of programming or working on advanced-level engineering products.

This article will study microcontroller architectures, their features, and use cases of microcontrollers in the real world. Special attention will be given to the relationships of different families of PIC microcontrollers, the processes of programming PIC microcontrollers, and their applications across multiple industries.

A PIC microcontroller is a type of microcontroller developed by Microchip Technology that previously held the title of Peripheral Interface Controller, or PIC for short. They have been used in embedded systems because of their low cost, low power use, high versatility, and wide range of available options.

PIC microcontrollers are usually present in consumer electronics, industrial automation, automotive systems, and small DIY projects. From all these domains the low cost and reliable PIC microcontrollers are preferred due to the advantages provided by the vast support ecosystem, tiered performance and memory options, and the ease of programming provided by the RISC (Reduced Instruction Set Computer) architecture.

RISC-based architecture is prominent in any PIC microcontroller CPU core. The beauty of these designs is having a small instruction set, resulting in faster execution and lower power consumption, and lowering of many other overheads. Instruction cycles are usually done between one to four clock cycles, depending on the device family.

Their performance varies depending on the family of the microcontroller. Baseline models tend to offer simpler capabilities such as control tasks while advanced 32 bit PIC microcontroller models like the PIC32 microcontroller come equipped with high-speed processing capabilities for complex operations usually backed by RTOS (Real-Time Operating Systems).

The RISC architecture's performance efficiency ensures reliable execution and consistency, providing dependable performance which makes PIC microcontrollers ideal for time sensitive embedded applications. Furthermore, advanced cores with pipelining architectures also improve instruction processing, which enhances multitasking capabilities in real-time systems.

These are the three types of memory resources incorporated in a PIC microcontroller:

• Flash memory is non-volatile and preserves the program being executed while keeping the device powered off.

• SRAM (Static RAM) is a volatile form of random access memory that is used to hold data temporarily while being processed.

• EEPROM is a type of non-volatile memory used to save data that should survive reboots, like configuration or log files.

Different models of the microcontroller support different amounts of memory, which provides flexibility for developers to select devices that meet their application parameters.

For example, lower-level 8-bit PIC microcontrollers are equipped with several hundred bytes of SRAM and several kilobytes of Flash and are perfectly suited for simple operations like reading sensor data or flashing LEDs. Meanwhile, higher level 32 bit PIC microcontrollers are equipped with several megabytes of Flash and several kilobytes of SRAM which makes them suitable for tasks like multimedia processing or executing real-time applications.

Components of PIC microcontrollers have hybrids of integrated peripherals like:

• Calendar and clock timers to measure time and count activities.

• Analog sensors’ interfaces are managed by ADC or Analog to Digital Converters.

• PWM or Pulse Width Modulated motor controls and other signal generators.

• Digital or general purpose I/O operatives and ports.

All these modules do not need external components. The advanced models have flexible pin mapping, so the board layout and complexity can be vastly improved since designers can assign I/O functions to the most appropriate pins.

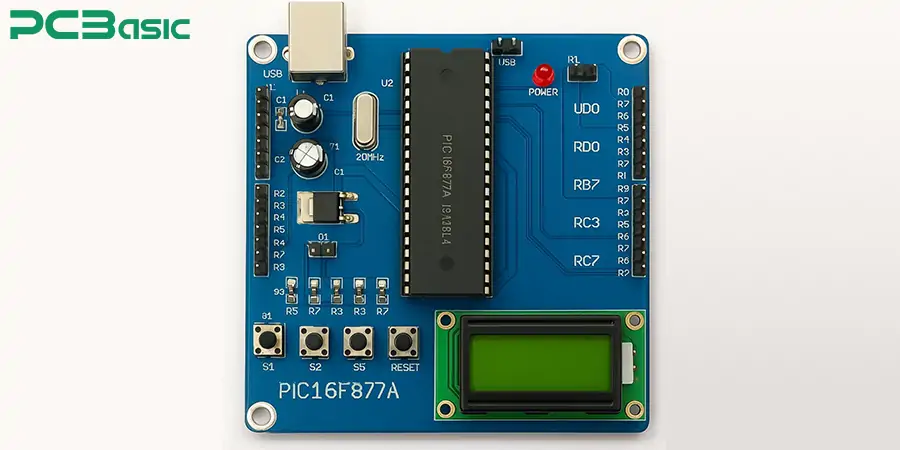

To promote inter-device communication, PIC microcontrollers feature multiple communication protocol support:

• Serial device communication is done through UART or Universal Asynchronous Receiver/Transmitter.

• SPI or Serial Peripheral Interface allows data to be transferred at high speeds and in full-duplex mode.

• Less pins are needed with I2C or Inter-Integrated Circuit in multi-device connection.

• CAN or Controller Area Network can be used in industrial and automotive applications.

• USB provides a simple way of connecting and controlling the PC directly.

These add-ons plug into bigger systems easily and help connect many devices. As an illustration, a smart thermostat may be using UART for communication with a display and I2C for acquiring data from sensors. It might even use Wi-Fi to interface, through SPI, to the cloud, advancing all this using a PIC microcontroller.

Whether internal or external, the clock system of PIC microcontrollers uses a range of oscillators. Lower costs and increased convenience are the results of using an internal clock, while greater accuracy and stability and increased frequency is a byproduct of using external oscillators.

Both aspects pick up work speed and increase the energy used. Dynamic changes to the frequency and increased power-saving states allow for using energy more skillfully. Many PIC microcontrollers come equipped with these features.

In portable applications, such as handheld meters or wearable devices, switching dynamically between fast and slow clocks enables longer battery life and optimizes power consumption.

Specialized families of microcontrollers targeted towards specific applications have been formed for use in PIC microcontrollers:

|

Family |

Bit Width |

Key Features |

Ideal For |

|

Baseline |

8-bit |

Low set of instruction, very minimal peripherals |

Tasks of Simple control, cost-sensitive apps |

|

Mid-Range |

8-bit |

More instructions, enhanced I/O and timers |

Entry-level embedded systems |

|

Enhanced PIC16/18 |

8/16-bit |

Advanced peripherals, more memory, much better speed |

Home automation, smart appliance |

|

PIC32 Series |

32-bit |

Higher performance, USB/Ethernet, RTOS support |

Complex application, multimedia, IoT |

Baseline and Mid-Range (8-bit)

These families are ideal for straightforward applications. They offer basic digital I/O, timers, and small memory footprints, making them perfect for budget-conscious projects like automation and LED control. The 8-pin microcontroller models in this family are especially suitable for space-constrained environments.

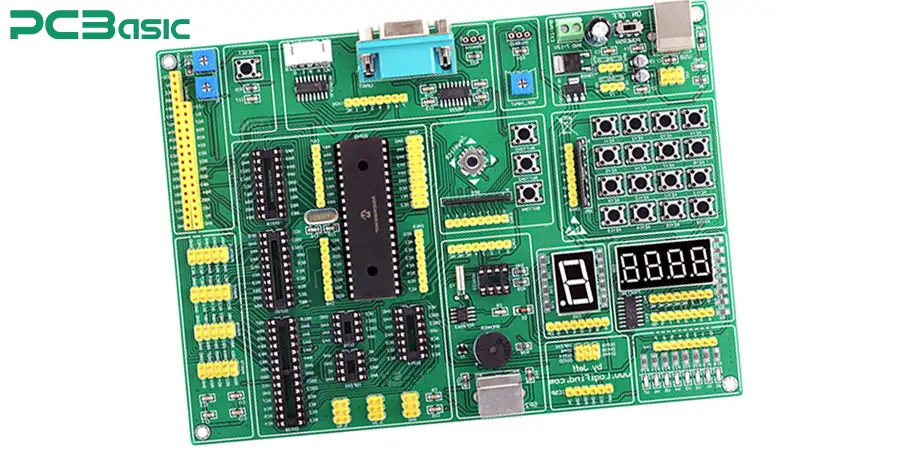

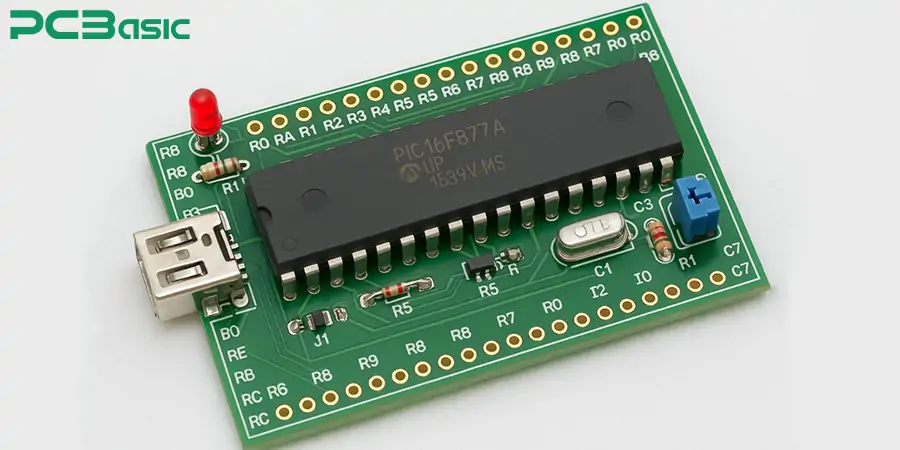

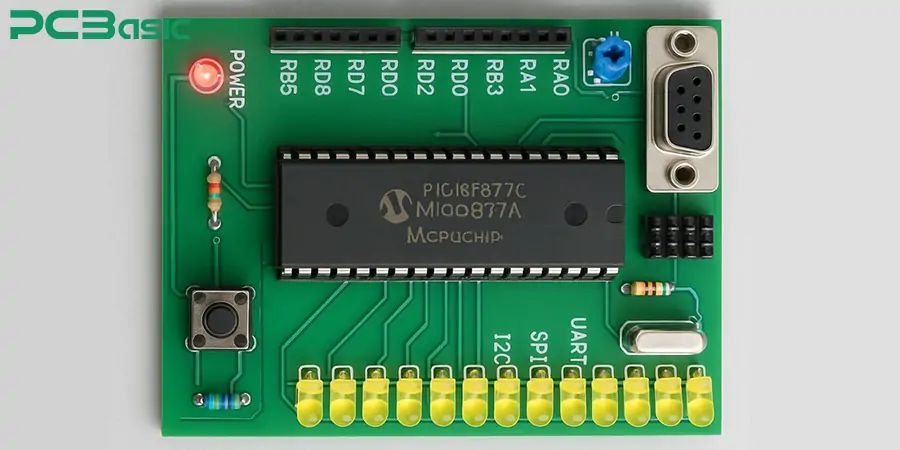

Enhanced 8/16-bit PICs

The PIC 16F877 microcontroller, and PIC microcontroller 18F series are some of the enhanced 8 and 16 bit controllers with more integrated memory and output options. They are widely used for smart home systems and basic computational devices that require mid-level processing and networking due to their moderate processing requirements.

PIC32 Series (32-bit)

The PIC32 microcontroller chips are ideal for more advanced tasks. They're integrated into Ethernet-based devices, USB peripherals, and audio processing due to their support for high-speed interfaces and external memory, real-time operating system compatibility, and other system requirements.

The PIC32MX and PIC32MZ families are equipped with several DMA channels, multi-layer buses, and large RAM options, making them suitable candidates for more sophisticated graphical user interfaces, Linux, or embedded alternatives.

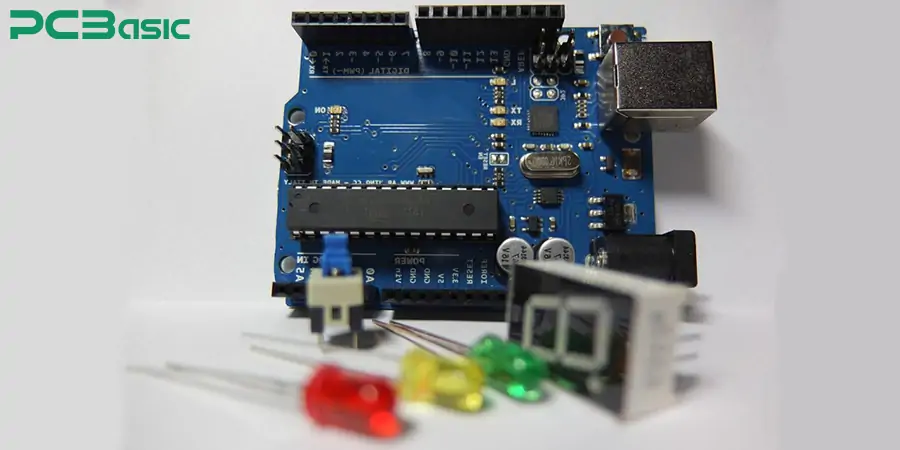

Developing a PIC microcontroller involves a variety of procedures and tools at your disposal:

• Selecting the Suitable PIC: Evaluate the device's memory, speed, peripheral, and power consumption.

• Development Tools: Coding, simulation, and debugging should all be done in MPLAB X IDE, combined with XC that translates your code into machine language.

• PIC Programming Hardware Devices: You can program and live debug your hardware on a PICkit or ICD (in-circuit debugger).

• Workflow Essentials:

1. Write your code in MPLAB X IDE

2. Compile the code through the XC compiler

3. PIC kit/ICD allows you to program the PIC microcontroller board

4. Live debugging through watch windows and breakpoints

First-Time Developers

Make sure to configure your Configuration Bits properly, determining the oscillator source, watchdog timer, and startup settings—all of which affect how a PIC microcontroller is programmed.

• Input the appropriate header files for your device, as they contain information about registers and macros.

• Make use of simulation tools located in MPLAB X and use them to test your code before running it on the hardware.

Microchip offers a wide range of code example libraries and documentation within the MPLAB Code Configurator (MCC), which is a plugin for the IDE permitting automatic initialization code generation. This automation alleviates the workload from developers when they need to configure the peripherals which subsequently enhances the overall development speed.

Schedulable advanced industrial controllers (PIC microcontrollers) have found usefulness in various fields, which include:

· Consumer Electronics - Used in remote controls, smart home devices, and other household gadgets.

· Industrial Systems - Their reliability and flexibility make them popular in monitoring devices, control systems, and process automation.

· Automotive Applications - Implemented for control of the engine, dashboard units, and communications with different kinds of sensors.

· Data Logging and Measurement - Ideal for interfacing with environmental sensors and for collecting data and storing it in EEPROM.

· For Educational and Hobby Projects - Low priced and well documented makes them popular among learners and enthusiasts.

Besides the applications mentioned above, PIC microcontrollers are now incorporated into medical equipment, automatic irrigation for farming, and wireless sensor networks. The customizability, tough protection from rough conditions, and strong resistance to interference are some of the many reasons why they are used in rugged surroundings.

In embedded systems, PIC Microcontrollers stand as a foundational technology. Their construction, range of applications, and ever-evolving peripherals suggest their use versatility spanning from LED blinking to intricacy of IoT gate ways. Thus, PIC Microcontrollers also serve to broaden the prospects for electronics projects, and widen the career landscape, inviting people from all walks of engineering, right from beginners to experts.

Amidst the blazing pace of development in the world of embedded systems technology, the functionality and versatility offered by PIC Microcontrollers is proving, and promises to be, ever more crucial. To adapt to future technologies centered towards smart devices, it is now more than ever necessary to engineer solutions based on modern day needs.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.