Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

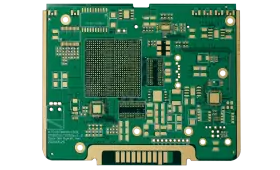

Conventional PCB solutions including single-layer, double-layer, and multi-layer boards for general electronic applications.

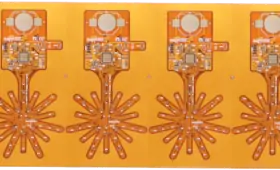

Bendable and space-saving PCB solutions ideal for compact devices and applications requiring flexibility.

Combination of rigid and flex board technologies, perfect for complex 3D electronic packaging applications.

High-end PCB solutions leveraging cutting-edge technologies tailored for specialized applications.

We have a variety of product cases for your reference.

Each step in the PCB manufacturing process adheres to strict inspection standards.

01File Review

02Inner Layer Fabrication

03Drilling

04Through-Hole Plating

05Outer Layer Fabrication

06Solder Mask Application

07Surface Finish

08Electrical Testing

09Final Inspection

10Packaging

Upload Files

Upload Files

Submit your Gerber files, BOM (Bill of Materials), and any project-specific requirements to us.

Technical Review

Technical Review

Our engineering team will review your files and verify technical specifications

Receive Quote

Receive Quote

Get a detailed quote including pricing, lead time, and shipping options.

Confirm Order

Confirm Order

Review and confirm your order details, then proceed with payment to start production.

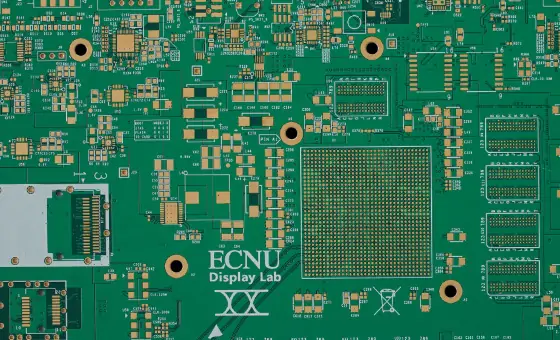

Established in Shenzhen, China, in 2011, PCBasic boasts more than 15 years of hard work and innovation in the field of PCB & PCBA manufacturing. The considerable expertise in printed circuit boards and decades of industrial experience grant PCBasic the confidence and strength to overcome challenges and deliver the best-in-class PCB & PCBA solutions, making it one of the leading PCB & PCBA manufacturers around the globe.

Learn MoreStrictly comply with ISO9001, IATF16949, and ISO13485 standards.

Rapid delivery for small batch products--within 24 hours at the fastest.

PCBasic is equipped with a professional R&D team and possesses a self-invented intelligent production management system.

No MOQ, even can get PCBs free!

With multiple supply chains, PCBasic can offer the best quality at the most competitive prices.

PCBasic guarantees a full refund in case of quality problems.

Serves more than 100 countries around the world

Has over 120,000 global customers in PCB prototype assembly service

Handles 1000+ pieces of PCB design and layout order documents every day

Boasts 96.15% on-time delivery in PCBA service

Discover everything about MCPCB in this guide. Learn what an MCPCB is, its structure, materials, types, applications, and how it compares to FR4 and ceramic.

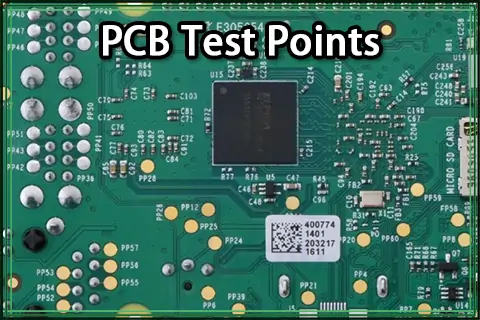

Discover everything about PCB test points: definition, importance, types, PCB testing methods, design guidelines, common mistakes, and some FAQs about PCB test points

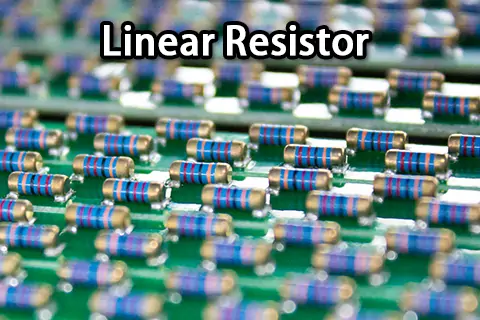

Learn what a linear resistor is, its key types, characteristics, and how it differs from nonlinear resistors.

More Than 100+ Patent Certificates

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.