Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Explore our factory through a 360° Virtual Tour

Take a one-minute journey into our smart factory. Discover our advanced equipment and powerful production capabilities. Start your immersive factory tour now.

-360° Virtual Tour

A leading PCBA manufacturer specializing in fast SMT assembly for small and medium batches, trusted by industries including industrial control, smart home, medical, automotive, IoT, and more.

Online Quote

Upload PCB File

Order Review

Payment

Real-time Fabrication Tracking

Delivery

Confirm Received

PCBasic offers high-quality PCBA solutions across various industries, including medical, aerospace, military, industrial, telecom, LED, electronics, and more.

How to Order PCB Assembly Services on PCBasic?

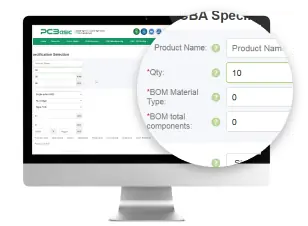

Enter the quantities to instantly get a PCB assembly quote. If you’re not sure about the number of unique parts, SMT pads, or through-holes, you can leave those fields blank.

Enter the quantities to instantly get a PCB assembly quote. If you’re not sure about the number of unique parts, SMT pads, or through-holes, you can leave those fields blank.

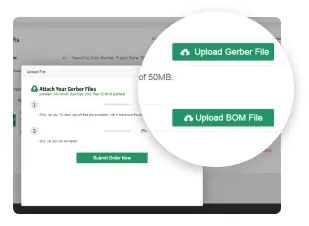

Upload your Gerber files, Bill of Materials (BOM), and Centroid files so that we can provide you with a faster and more accurate quote.

Upload your Gerber files, Bill of Materials (BOM), and Centroid files so that we can provide you with a faster and more accurate quote.

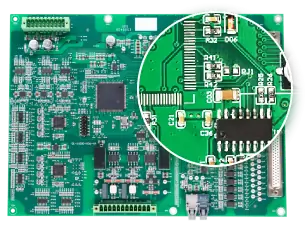

During production, we will send sample photos for your confirmation. If testing or programming is required, please provide the testing method or programming plan in your quotation request.

During production, we will send sample photos for your confirmation. If testing or programming is required, please provide the testing method or programming plan in your quotation request.

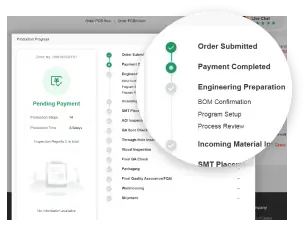

During production, you can view the order process and progress in the PCBasic dashboard. If you have selected a testing service, you can also view the test report files there after the tests are completed.

During production, you can view the order process and progress in the PCBasic dashboard. If you have selected a testing service, you can also view the test report files there after the tests are completed.

Our PCB Assembly Solutions

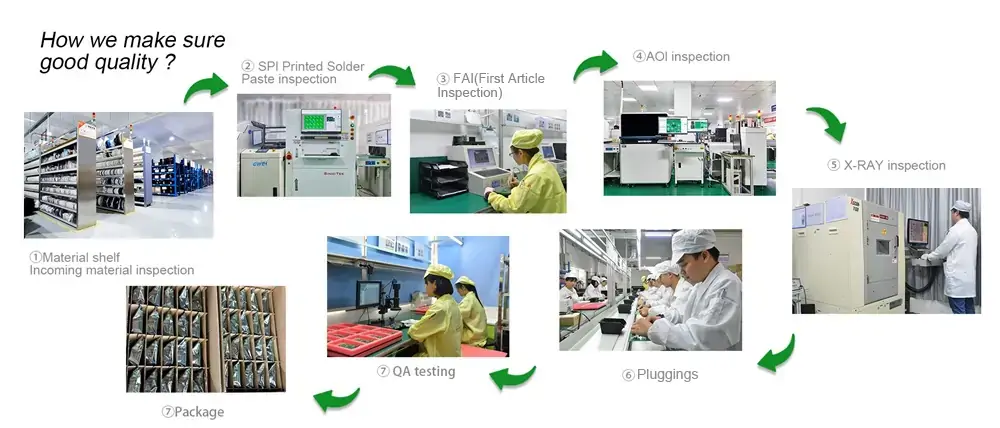

Our fully automated SMT line includes 9 inspection processes to ensure the highest quality for you.

Prevent process defects caused by material issues during production and avoid efficiency losses due to non-compliant quality of refurbished materials.

Detect solder paste printing defects to prevent them from entering the next process.

Check for any errors, omissions, or defects in the PCBs to prevent them from flowing into the next process.

Verify the accuracy of the placement process on the production line and ensure each component's parameters are within standard limits.

Conduct random inspections of all production processes to ensure compliance with the work instructions.

Inspect the solder joints of components that are invisible to the naked eye to ensure the reliability of BGA solder balls.

Inspect finished PCBA according to the IPC-610 inspection standard.

Conduct strict inspections before shipment, along with barcode scanning verification, to prevent defective products from being shipped.

Strict inspections are carried out before shipment, with scanning and verification to ensure no defective products are shipped.

Established in Shenzhen, China, in 2011, PCBasic boasts more than 10 years of hard work and innovation in the field of PCB & PCBA manufacturing. The considerable expertise in printed circuit boards and decades of industrial experience grant PCBasic the confidence and strength to overcome challenges and deliver the best-in-class PCB & PCBA solutions, making it one of the leading PCB & PCBA manufacturers around the globe.

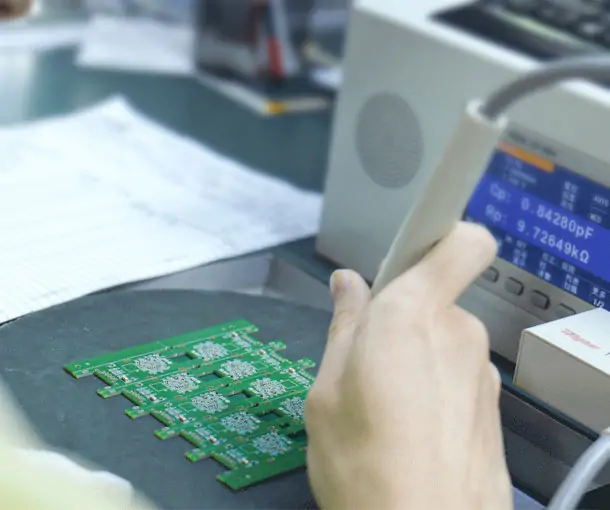

PCBasic is dedicated to delivering exceptional PCBA quality control through our comprehensive inspection process, utilizing advanced equipment across our facilities and extensive partner network. We ensure meticulous attention to every detail, guaranteeing the highest standards of quality for each assembly.

PCBasic prioritizes rigorous compliance to ensure the highest quality and safety of our PCBA products. We partner with third-party certification bodies for regular testing and certification, meeting all necessary standards.

Choose us for your PCBA needs and experience global market success with a trusted and certified partner.

PCBasic proudly holds a range of industry certifications, ensuring the highest standards of quality, reliability, and compliance in PCB and PCBA manufacturing.

At PCBasic, we encourage customer visits, providing a chance to tour our cutting-edge facilities and see our PCB and PCBA manufacturing capabilities in action.

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Asking QuestionsView All

Asking QuestionsView All

Customers' Feedback