Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Do you know the magic behind bending and flexing electronic devices is Flex PCB Assembly? Flex PCB Assembly is an invaluable cornerstone of modern electronics innovation and efficiency.

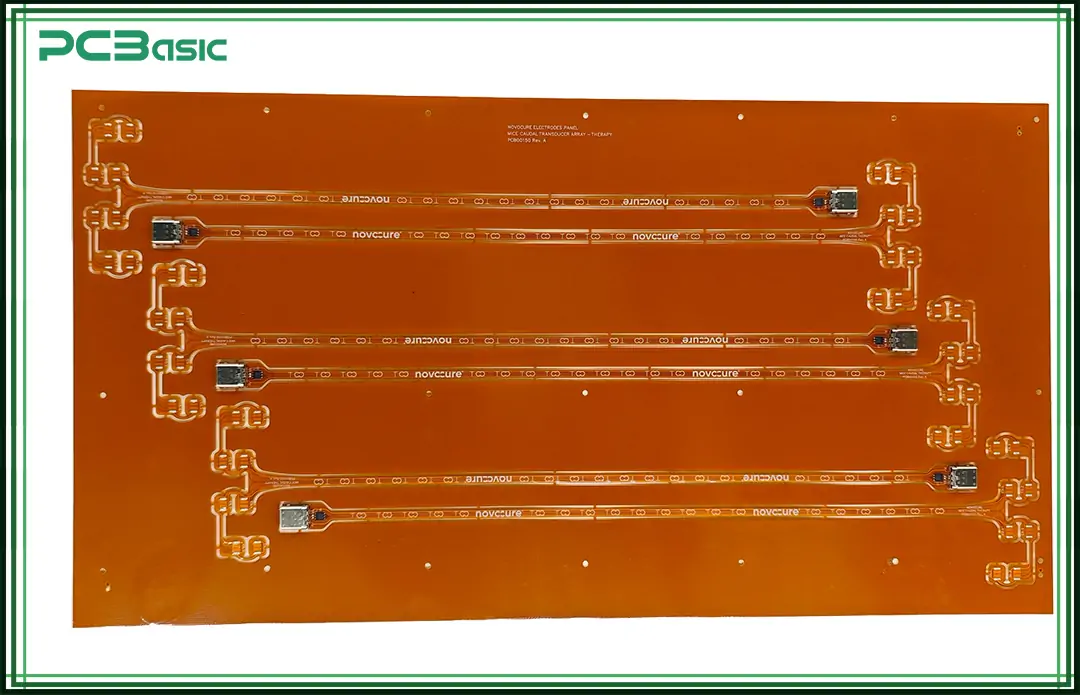

Imagine a circuit board that can twist and turn into your favorite gadget's tiniest spaces. That's what Flex PCB Assembly does. It brings a new level of flexibility to the world of electronics. Component assembly on a flex board is known as flex PCB assembly.

This blog will explore the core of the Flex PCB assembly process. Also, we will discuss the applications, future outcomes, and emerging trends related to Flex PCB. Let us navigate the dynamic landscape of Flex PCB assembly.

Flex PCB, also known as FPC (Flexible Printed Circuit), is a type of circuit board that can bend, fold, and twist. It is made of very thin and flexible materials, such as polyimide or polyester film, making it lighter and thinner than traditional rigid boards.

Flexible boards can be installed in small or structurally complex spaces. They are widely used in mobile phones, laptops, digital cameras, wearable devices, medical instruments, and automotive electronics. FPCs are commonly used to connect different modules and transmit signals, especially in areas where moving parts need to be linked.

Flex PCB assembly means mounting electronic components onto the flexible board. Since the board is soft and cannot be mounted directly like a rigid board, it must first be fixed onto a special carrier board before carrying out operations such as component placement, soldering, and inspection.

Because flexible boards are more prone to deformation, the requirements for equipment and operator skills are higher. This type of assembly is suitable for electronic products that require high circuit density and compact size.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

In the early 20th century, researchers of the Burgeoning Telephone Industry felt the need for alternative layers of conductors to produce flexible electric circuits.

During the same time, notebooks of Thomas Edison proposed coating linen paper with cellulose gum. It gave the idea of outlining circuits on the gum with the powder of graphite.

During the late 1940s, many companies took patents for photo-etching circuits on a flexible substrate.

Flexible Printed Circuit Boards have come a long way since they were first introduced.

Over the last two decades, Flex PCBs have become an imperative part of emerging technologies. Today, you can notice their use in electronics, medicine, IoT devices, and wearables.

Several kinds of flexible PCBs are available in the market. Each comes with its benefits.

The most common ones include:

Single-sided

Double-sided

Multilayer boards

Single-sided flex PCBs are better for simpler systems such as LED lights or LCD modules. Thus providing more excellent sturdiness than their double-sided counterparts and making assembly simple.

Double-sided flexible printed circuit boards (flex PCBs) are flexible printed circuits. They contain two conductive layers separated by polyimide insulation. It is for use in applications where you need access to both sides of traces.

While more durable than single-sided flex circuits, double-sided boards require additional space. It is due to the additional layers.

Here’s a detailed comparison between different types of Flex PCBs.

|

Item |

Single-sided Flex PCB |

Double-sided Flex PCB |

Multilayer Flex PCB |

|

Number of Conductive Layers |

1 layer of copper |

2 layers of copper |

3 or more layers of copper |

|

Plated Through Holes (PTH) |

Not required |

Required |

Required |

|

Structural Complexity |

Simple |

Moderate |

High |

|

Flexibility |

Best (most flexible) |

Moderate |

Lower (due to multiple layers) |

|

Cost |

Lowest |

Moderate |

Highest |

|

Typical Applications |

Simple connections, membrane switches, LED strips |

Camera modules, portable devices |

Medical, aerospace, military |

|

Manufacturing Difficulty |

Low |

Medium |

High |

|

Signal Integrity |

Poor (no shielding or differential pairs) |

Good (supports differential design) |

Excellent (full signal management) |

|

Component Load Capacity |

Low |

Medium |

High |

Using Flex PCBs has a lot of advantages:

• Flexibility: Flex PCBs can bend, fold, and twist, allowing routing in three-dimensional spaces. This is ideal for complex and compact device designs.

• Space and Weight Saving: Compared to rigid PCBs, flex PCBs are thinner and lighter, helping reduce the overall size and weight of electronic products.

• Vibration and Shock Resistance: Their flexible nature allows them to absorb mechanical stress, making them more durable in high-vibration or impact environments.

• Greater Design Freedom: Designers can create innovative configurations and integrate electronics into non-traditional shapes and spaces.

• High Reliability: Fewer interconnections and solder joints mean fewer potential points of failure, improving overall circuit reliability.

• Suitable for Dynamic Applications: Perfect for devices that require constant movement or folding, such as flip phones, camera modules, and wearable devices.

Electronic devices come in all sorts of shapes and sizes. What they all share in common is using rigid-flex circuit boards.

Rigid-flex PCBs allow designers to maximize space utilization and achieve unique form factors. Thus, enabling them to pack more functions into smaller spaces. At the same time, their superior thermal performance makes them suitable for aerospace applications.

Industry Applications: Here are the industrial applications of Flex PCBs.

For years, flex PCBs have become an integral component of automotive electronics. It gives cars and other vehicles more functionality. This industry faces the challenge of creating more intelligent and efficient electronic systems for modern vehicles.

The manufacturer could design electronic systems adapted to the vehicle's contours by incorporating bendable circuits. This approach reduced the electronic components' overall weight. Further, it allows for more creative and space-efficient layouts.

Aerospace is another industry that relies heavily on flexible circuits. The challenge was enhancing electronic components to withstand the rigors of aerospace conditions. Also, it reduces the overall weight of critical systems. The firm achieved a remarkable balance between durability and flexibility.

They do so by integrating bendable circuits into crucial aerospace electronics. Navigation systems, communication devices, and control panels embrace Flex PCBs' lightweight and adaptable nature.

In the medical field, Flex PCBs are not just components; they're lifelines. The challenge was to create advanced medical devices that offered precision and flexibility.

By incorporating bendable circuits into the design of medical devices, the manufacturer achieved a breakthrough in form and function. Wearable health monitors, implantable devices, and diagnostic tools now boasted a level of flexibility earlier unthinkable.

Flex PCBs are the silent heroes behind sleek and innovative devices in consumer electronics. Delve into case studies highlighting their role in smartphones, smartwatches, and other cutting-edge gadgets. The challenge was integrating advanced technology while maintaining a slim and stylish design.

The company achieved a breakthrough in design flexibility by adopting Flex PCB Assembly. These bendable circuits allowed for intricate layouts, fitting seamlessly into the slim contours of smartphones, smartwatches, and other portable gadgets.

Flex circuit assembly requires special skills and equipment due to its flexible materials. Remember, any misstep during production could cause severe damage to the final product.

The choice of materials has an immense effect on both performance and application. The substrate and adhesive used in flexible PCBs need to be strong. They have sufficient adhesion because they will be bent and flexed repeatedly.

A high-performance flex adhesive and a dynamic, high-quality flex substrate can avoid stress-induced failure. Selecting appropriate conductive materials also helps prevent stress-related fatigue. Also, it guarantees that current ratings stay controlled.

Below are the steps to assemble flex PCBs.

First, a flex assembly manufacturer puts together components and materials used throughout the process. It ensures a clean and organized workspace.

Some primary materials include:

Flex PCB

Soldering equipment

Electronic components

Safety gears, etc.

The process helps in minimizing the moisture content inside the flex board. The baking process may last up to 6 hours at 120 °C. However, it all depends on the thickness of the flex PCB. Slim flex boards take less time.

Once the flex board is completely dried, it is time to apply solder paste on its surface. The aim is to create solder pads onto the circuit board. Generally, professionals do it by screen printing the solder past with the help of a stencil.

In this process, PCB engineers make pathways of insulation ink on the circuit. It helps in identifying test points, warning symbols, and components.

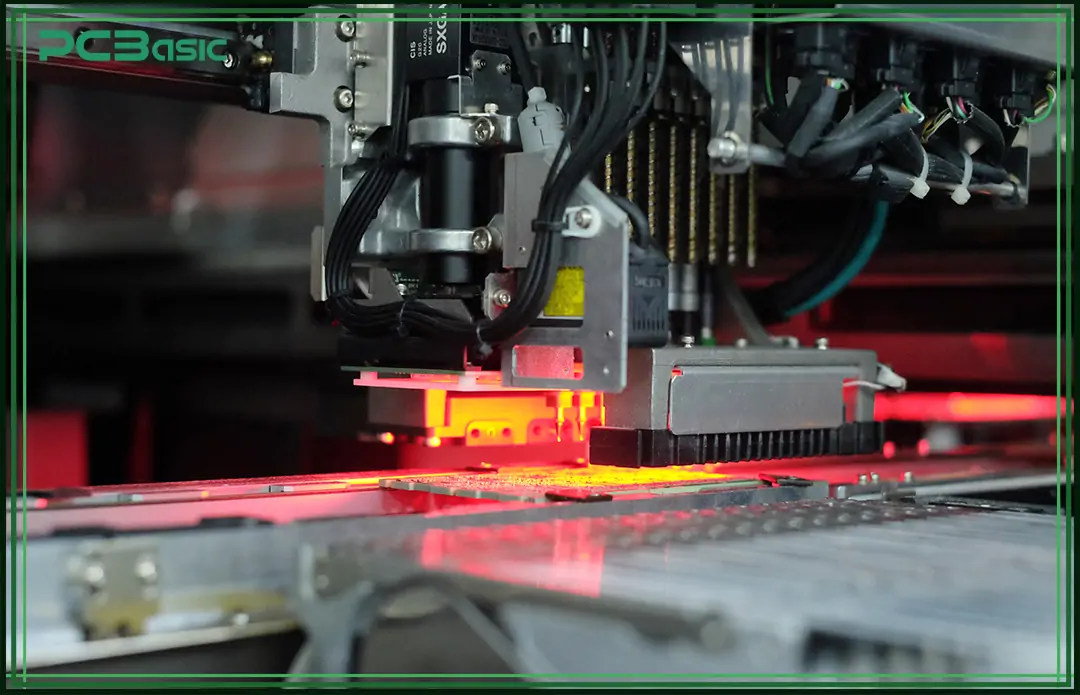

In this step, engineers place all components onto the flex PCB. Generally, it is started with surface-mount components.

Once the components are placed, they are carefully soldered. Minor connections and cold joints need more attention during the process.

In this step, engineers inspect the assembled PCB for all possible defects. It involves checking soldering, component placements, and physical damage.

In the last stage, the flex PCB assembly manufacturer checks if the board is working as intended. They also check for faulty connections and short circuits.

As mobile phone makers add advanced features like cameras, fingerprint sensors, 3D sensing modules, and more, rigid-flex circuit boards are increasingly in demand.

Flex PCBs can reduce costs by supporting such features in smaller volumes compared with their non-rigid counterparts. This happens due to the reduced number of extra connectors/cables needed, plus reduced assembly times, resulting in cost savings.

New materials are revolutionizing how flex PCBs are designed and manufactured. One such material, liquid crystal polymer (LCP), allows thinner PCBs to be produced while being more resistant to moisture and chemicals than their predecessors.

This makes LCP an excellent material choice for electronics that must withstand harsh environments, like aerospace piloting displays or medical appliances with limited space requirements.

Advanced manufacturing techniques are also aiding flex PCB production costs by streamlining production and increasing productivity. This leads to lower unit costs and balanced performance-affordability relationships between substrates and materials. For instance, high-performance materials may come at a higher price point but offer greater durability and miniaturization benefits.

The PCB industry is constantly evolving and progressing at a rapid pace. As an advancement, flex circuit boards can adapt to various shapes and sizes and withstand temperatures without breaking apart or overheating. Unfortunately, the assembly of such boards may be both complex and time-consuming.

Various approaches have been taken to reduce the costs of flex circuit assembly. It includes using polyimide and polyester films that help lower assembly costs while improving end-product quality. Reflow soldering is an additional technique that incorporates preheating components to melt solder and progressively cooling them to form a strong bond.

In satellite applications, flex circuits are ideal for space allocation and thermal performance. Flex circuits can support unique shapes that rigid boards cannot support because of their capacity to absorb vibration and heat.

Many industries are seeing a rise in the use of rigid-flex PCBs. Unlike conventional rigid boards, these boards can bend and flex in specific places, simplifying assembly by requiring fewer interconnects and connectors.

Are you in search of a reliable flex PCB assembly service? Contact PC Basic JS Technology. We are one of China's top-rated PCB assembly manufacturers with customers worldwide.

PCBasic specializes in high-precision, high-reliability Flex PCB assembly, with full-process capabilities from design and fabrication to assembly — fully meeting the customized and high-standard demands across various industries.

Professional Design Capability

• A technical team with over 10 years of PCB design experience, well-versed in the complex structures and application scenarios of flexible PCBs

• Industry-academia collaboration with PhD teams from multiple universities, capable of handling advanced designs and new material integration

Flexible Manufacturing & Rapid Response

• Shenzhen factory focuses on small-batch, quick-turn production, ideal for diversified Flex PCB needs

• Huizhou factory supports medium to large-volume production with strong scalable manufacturing capability

• Self-operated stencil and fixture factories to flexibly meet special process requirements for Flex PCBs

• Stencil delivery in as fast as 1 hour, efficiently supporting prototyping and mass production

• One-click BOM import and instant quoting system, significantly improving order processing efficiency

Comprehensive Testing & Quality Assurance

• Equipped with flying probe testers, AOI, X-ray, functional testing, and other inspection systems for full-process quality control

• Uses only original, genuine components and an intelligent component warehouse system to ensure the reliability and consistency of every PCB

High-Level Certifications

• Certified with ISO13485, IATF 16949, ISO9001, ISO14001, and more

• Fully capable of meeting strict quality standards required by medical, automotive, and industrial control applications

Whether you're in the medical, aerospace, or electronics industry, we can meet your specific requirements.

Contact our sales team now to get Flex PCB assembly quotes.

In conclusion, Flex PCB has a blooming future due to its advantages in various applications. Their flexibility makes them like superheroes in electronics, fitting into tight spaces and bending without breaking. From powering your favorite gadgets to helping doctors with advanced medical devices, Flex PCBs are changing how we live and experience technology.

Looking ahead, their role in aerospace, consumer electronics, and healthcare is set to grow even more. They're on a journey to make our lives easier and our devices smarter.

So, keep in mind that Flex PCBs are the unsung heroes who make it all possible, whether you find the science behind them fascinating or just enjoy cool gadgets. Stay curious because the world of Flex PCB Assembly is full of exciting possibilities!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.