Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

In the fast-paced world of electronics manufacturing, surface mount technology (SMT) assembly is a pivotal innovation that has reshaped the way we produce printed circuit boards (PCBs). This article will take you on an in-depth look at the SMT assembly process as well as the pros and cons!

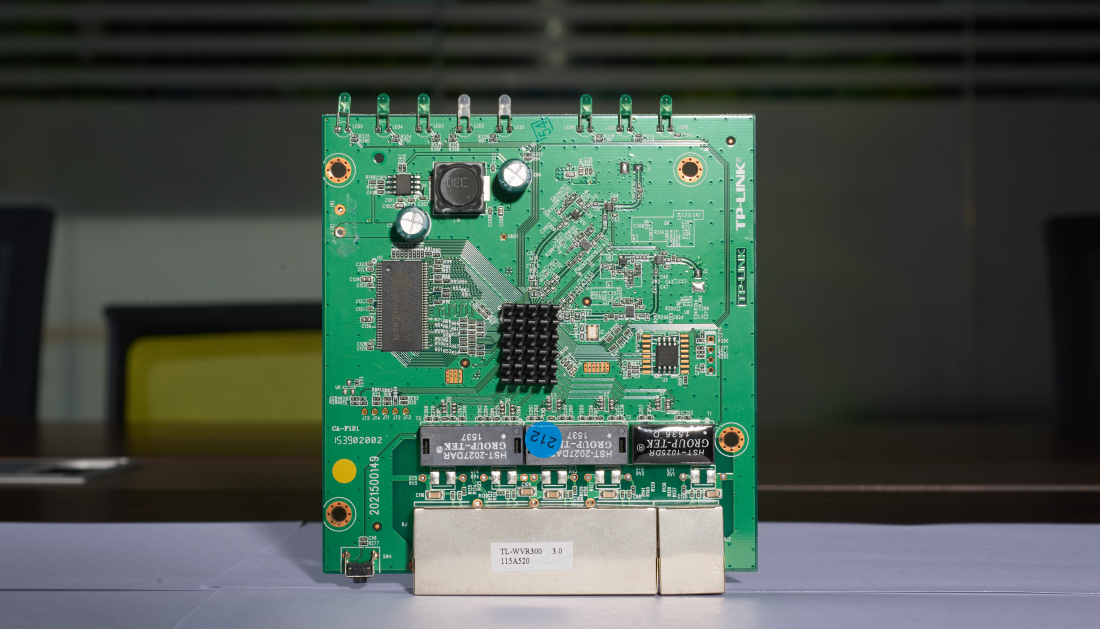

SMT's full name is "surface-mount technology". SMT assembly is the method of correctly placing and soldering the electronic components on the surface of the PCB using an automated machine. With the development of smart technology today, SMT assembly has replaced the traditional through-holes technology construction method of fitting electronic components. SMT assembly allows to increase manufacturing automation so that it reduces the manufacturing cost of PCBs greatly and leads to smaller boards.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

1. High density SMT assembly:

Based on technology development, electronic products becomes smarter and smarter, more and more sophisticated, it required that PCB assembly density need to be greatly improved. And SMT assembly solved this problem perfectly, it makes high density PCB assembly become possible.

2. Lower cost and faster produce speed:

Due to the features of standardization, automation and holeless mounting, smaller-size components mounting reduce a lot of cost than their larger through-hole PCB, reduce drilling and increase the speed of produce.

3. Higher performance:

Using electronic components with short-lead or no-lead, SMT assembly reduce parasitic inductance and capacitance from the leads, improves the frequency and speed performance of PCB. Keep the PCB and components out of heat effectively.

4. Reliable and stable:

Automated production machines ensures that every connection of the components are soldered well, SMT assembly improves the reliability and stability of electronic products.

5.More efficient use of pcb area:

Smaller electronic components and the technology of SMT allow SMT assembly to have a better use on the PCB's surface area.

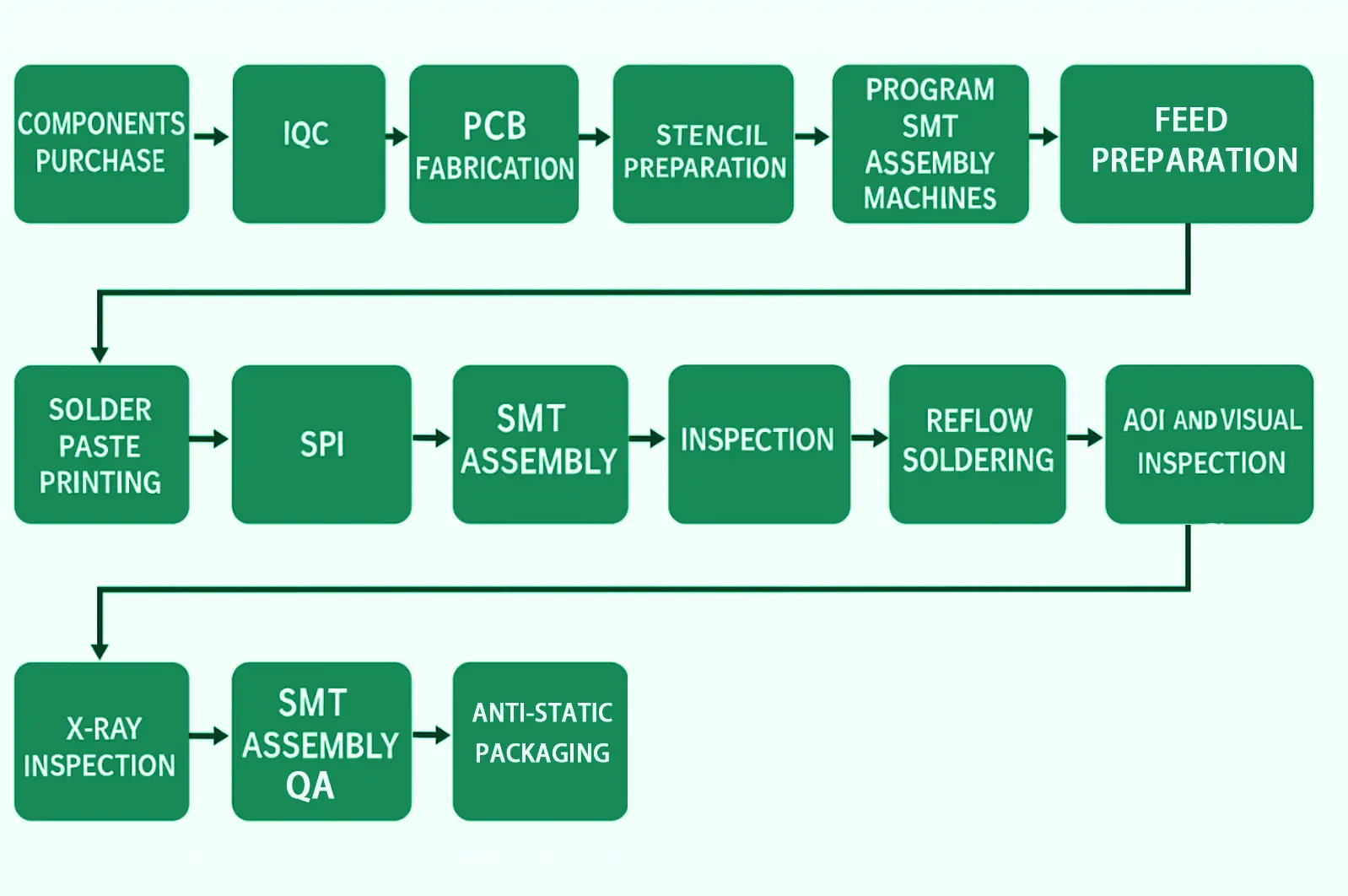

Normally, there are 16 processes in our company.

First, purchase the electronic components in need, IQC (income quality control) ensures every component is in good quality and less errors in feeding.

Secondly, put them into Smart material management system, every material has its own unique QR code to make sure projects produced correctly. When the project starts, we will scan its QR code to get the correct quantity and type of electronic components in need. It helps SMT assembly process will place the correct electronic components on the PCBs.

Third, PCB fabrication. Produce the PCB following the files of PCB requests. Make sure that every components have correct pads on the correct places. PCB fabrication. Produce the PCB following the files of PCB requests. Make sure that every component has the correct pads in the correct places.

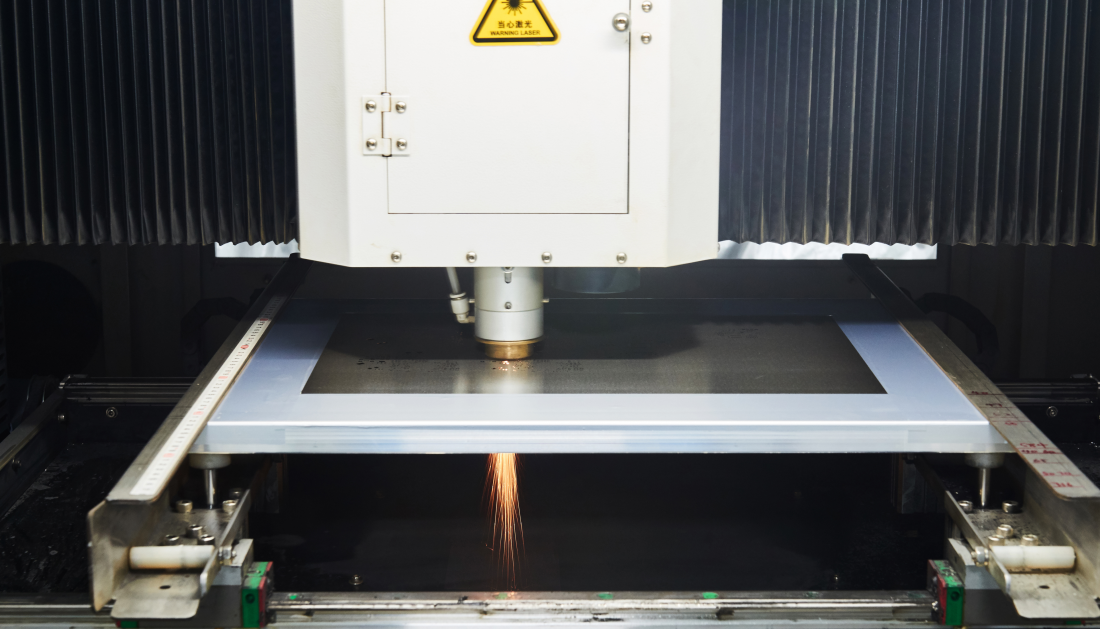

Fourth, stencil preparation; follow your PCB assembly files to make Stencils for the SMT assembly process; we use a Laser Printer to dig holes in the stencils in order to fit the pad on the PCBs. It will help the machines print the solder and paste it on the PCBs' pads.

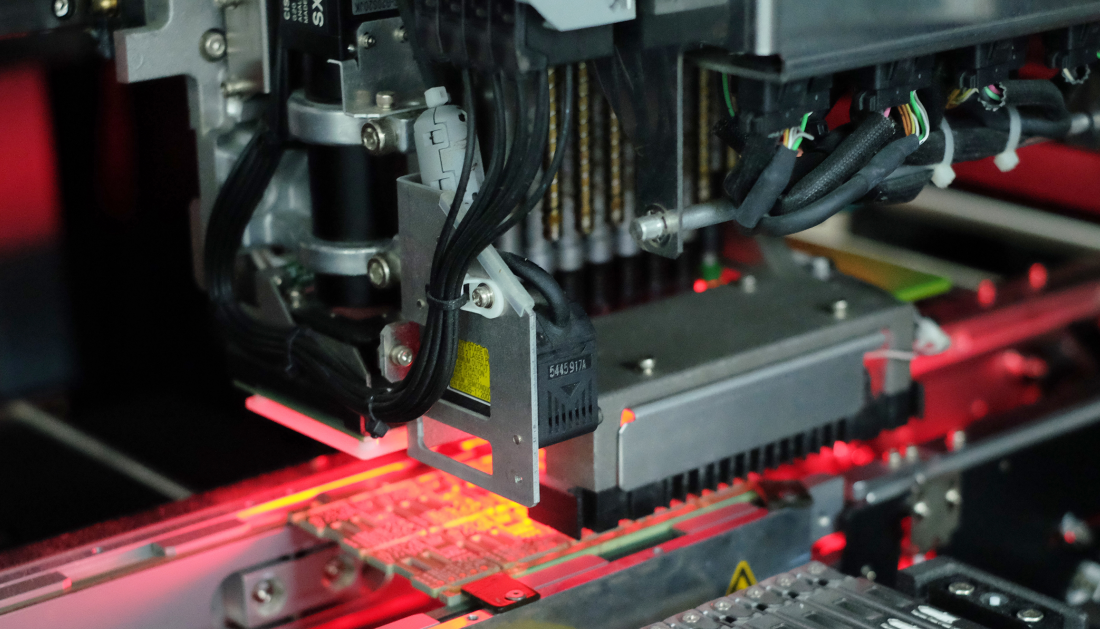

Fifth, program the SMT assembly machines to pick and place the electronic components on the PCB correctly.

Sixth, feed preparation. To get the electronic components from the smart management stock, put the feeds into SMT assembly machines by scanning the QR code of each kind of electronic component; if you scan the wrong QR code, the machines will give you an error. In this way, we have fewer errors than other manufacturers.

Seventh, solder paste printing; solder paste is a mixture of flux and tin; printing machines print the solder paste on the PCB by using a squeegee. It is an important thing to design the thickness of stencil and adjust the pressure of the squeegee, the thickness of solder paste on the PCB depends on them. It will have a great influence on the next processes. So, it needs to be scientific, refined and standardized.

Eighth, SPI (solder paste inspection), One of the important processes for SMT assembly. It is a machine to check the solder paste on the PCB, Solder paste inspection machine adds a laser device for solder paste thickness measurement, through checking Solder paste's printing volume, the height, area, flatness to make sure components soldered better.

Ninth, pick and place electronic components on PCBs through high-speed SMT assembly machines. Each feeder is able to pick and place the electronic components of 0201 and upward. During this step, SMT assembly machines pick the correct components and place them on the PCBs accurately following the program. This process enables fully automated assembly and most SMT assembly machines can place over 40k components per hour.

Tenth, inspect before reflow soldering, check whether the machine printed solder paste well on the PCBs. if well, it will be sent to the next process, if not, PCBs will be sent back to the last process until it passes the checking.

Eleventh, reflow soldering. During this step, the point is to melt the solder paste and make the tin climb on the connections of components, then solidify. After the PCBs leave the SMT assembly machine, it will be sent to reflow oven. It has 10 different temperature zones, which will heat the PCBs and solder paste.

During hot gas soldering, the energy for heating up the solder joint is transmitted by hot gas. This can be air or nitrogen. In the reflow oven, PCBs will be heated to about 235-255℃, which is higher than the melting point of solder paste. Within the temperature, you need to consider the heat resistance of components. Solder paste is melted after heating, and flux helps the tin climb on the connections of the components and then solidify.

Twelfth, the next step is AOI (Automated Optical Inspection). After reflow soldering, check if there is no problem with the solder joint quality. With the development of 3D technology, it is more reliable to use 3D technology to check it than 2D inspection. Cause there are more errors by 2D inspection, through 3D physical optical imaging capabilities, 3D inspection allows to take more accurate measurements and provides an inspection process. As the tin hardens, components are affixed on PCBs, and the SMT assembly process is completed.

Thirteenth, X-ray inspection. After the SMT assembly, if the PCB has BGA and other flat contacts, a matrix of solder balls or terminations will be placed on the body of the component.

The size of the chip is also getting smaller and smaller, and the pins of the chip become more and more, especially the BGA chip that has appeared in recent years, because the pins of the BGA chip are not distributed around the conventional design but are distributed on the bottom of the chip.

There is no doubt that it is impossible to judge the quality of solder joints through traditional visual inspection. AOI can't inspect if the connections of components like BGA are soldered well, so another method is needed to help with the inspection. X-ray equipment can detect it by using the relationship between the penetrating power of X-rays and the density of materials and using the property of different absorption to distinguish materials with different densities.

Therefore, if the inspected object is broken, the thickness is different, and the shape changes, the absorption of X-rays is different, and the resulting image is also different, so a differentiated black and white image can be generated.

Fourteenth, leaning and drying. There are some oil and dirt in the whole production process and they may lay on the surface of the PCB, so the PCB needs to be cleaned and dried before next process. For example, soldering paste leaves behind some amount of flux, while human handling can transfer oils and dirt from fingers and clothing to the surface of the board.

Fifteenth, SMT QA. It is the last step of the SMT assembly process. QA (quality assurance). In this step, we check the PCBs again and test the PCB to test the result of the SMT assembly.

Sixteenth, anti-static packaging. Cause some electronic components are easily damaged by static electricity, preventing static electricity from them, and Anti-static packaging is necessary.

No matter how perfect your manufacturing factory is, it still has some troubles in production. Some of these troubles are caused by nature, the others occur due to manufacturing errors. Surface Mount Technology Assembly (SMT assembly) is one of those processes which experiences such errors, but almost all errors can be avoided.

This phenomenon is caused by bridging across two different components, then lead to electronic short. The reason is that when printing the solder paste, it generates excess solder on pcb and cause wrong soldering on the PCB pad. You could try to make stencil thinner to see whether difference happens.

Due to excessive humidity in the SMT assembly device, it creates these solder balls during the reflow solder process. Those balls may lead to electronic disruptions and some big balls of them will cause functional issues in PCB. Thus, necessary to reduce the humidity and moisture in the devices and please clean the bottom of the stencil as dirt may also build these solder balls.

This error has another name: “Manhattan Effect". It happens when one connection lead of electronic components raise and much higher than another lead, looks like a tombstone on the ground. Thus, this phenomenon got this name. Uneven heat distribution of solder paste is one cause of warping. The other reason is that electronic components aren't placed at correct positions.

It seems to be soldered on the surface; however, it is actually not soldered. When you test its function, sometimes it can pass the test, and sometimes it cannot, and it will show you its bad contact.

PCBasic is a global high-mix, high-volume, and high-speed SMT PCB assembly manufacturer with more than 15+ years of industry experience. Equipped with 8 advanced SMT lines, we provide efficient, stable, and traceable SMT assembly services to customers worldwide.

With factories in both Shenzhen and Huizhou, we can flexibly handle small-batch rapid prototyping and large-scale mass production. From SMT processing to component sourcing, stencil manufacturing, and quality inspection, we offer full-process solutions to accelerate delivery and ensure quality.

Professional SMT Manufacturing Capabilities

• 8 SMT production lines to support flexible order volumes

• Shenzhen factory for small-batch quick-turn services

• Huizhou factory for large-volume production

• In-house stencil factory with stencil delivery in as fast as 1 hour

• In-house fixture production for complex SMT needs

Efficient Material Management System

• One-click BOM import with automatic quotation generation

• Intelligent central warehouse for fast material turnover

• All components are 100% original and genuine, ensuring reliability and supply stability

Strong Engineering & Project Support

• 10+ years of PCB design and project management experience

• Industry-academia collaboration with PhD teams, enabling advanced and complex SMT solution development

Certified Quality Assurance

• Certified with ISO13485, IATF 16949, ISO9001, ISO14001, and UL

• A National High-Tech Enterprise & IPC member

• Holder of 20+ patents in quality inspection and production management systems

• Full range of testing equipment: AOI, X-ray, flying probe, and more to ensure SMT quality

Reliable Technical Support

• Dedicated teams in engineering, quality, and IT working in sync

• 24/7 technical response to support your project efficiently

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.