Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

The journey to manufacturing the correct electronic equipment begins with ordering a prototype PCB assembly. Imagine, after mass production of an electronic circuit board, you realize you made a mistake in the design. And that would mean starting all over the process. Not to mention the financial loss.

You can avoid such costly mistakes by going for PCB prototype assembly services. It lets you scrutinize your circuit board design and subject it to several functional tests. After that, you can launch the mass production of the assembly board without any fear.

The article takes you through the PCB assembly process, why it's necessary, and how to make an order for a PCB prototype assembly.

A printed circuit board assembly has complete components on it. After making new PCB designs or after effecting some changes, you need to confirm that there are no errors. Therefore, that calls for ordering the manufacturing of a sample printed circuit board.

A prototype PCB assembly is thus the testing assembly you order before beginning mass production of the board for commercial purposes.

It’s cheap and convenient to correct errors on a PCB prototype assembly. On the other hand, errors in a whole batch mean wasted time and money.

About PCBasic

About PCBasic

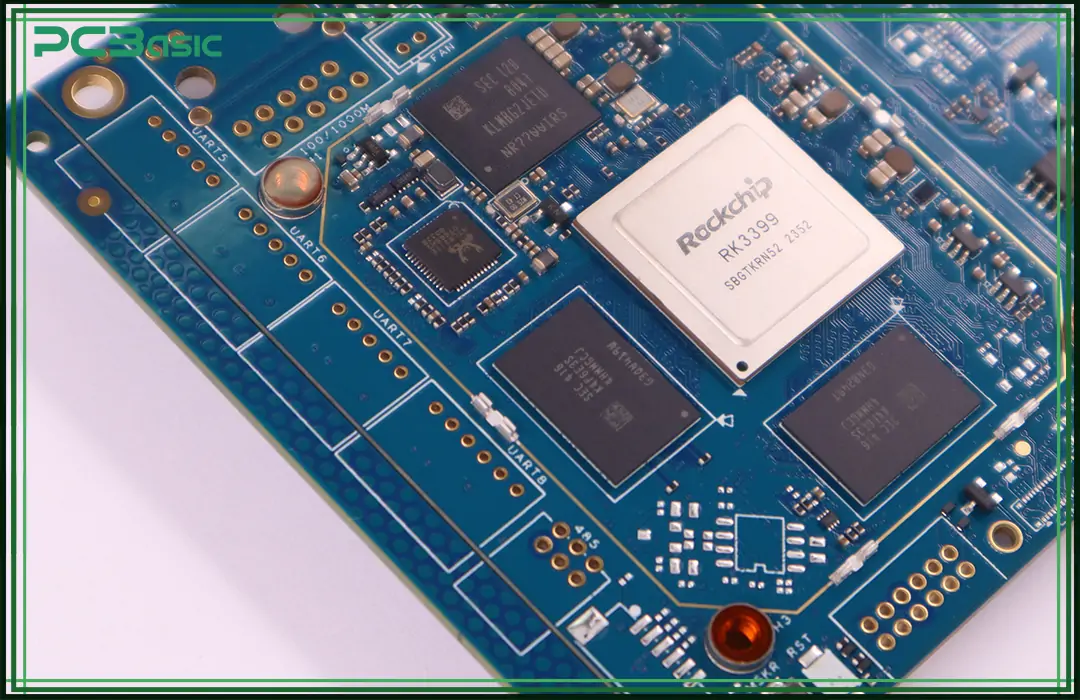

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Collaborating with a reliable company to handle your prototype PCB assembly services bestows you additional benefits:

The design teams test the individual components and the prototype. Whenever they unearth any mistakes, they fix them before reaching the consumer.

Also, presenting a sample before your potential customers is more convincing, which means less back-and-forth communication about the product.

You also benefit from the assistance of the manufacturing team. For instance, our professionals can suggest ways of improving the design to maximize its performance. Also, our prototyping team can point out potential mistakes DRC or you hadn’t spotted before.

One of the outstanding benefits of PCB prototype assembly is cutting down on production expenses. By pointing out errors before going for full-scale production, you avoid paying double the amount for the production of the items.

After running a successful prototype, you can approximate the demands of full-scale production. That is the projected timeline and range of materials it will take.

A design theory may appear convincing on paper. However, prototyping is solid proof of the working of an idea to improve a product.

Many people are claiming to provide top-notch prototype PCB assembly services. However, not everyone is trustworthy. So, take your time and dig deep to verify the claims of each manufacturer.

Here are solid reasons to choose us for your PCB prototype assembly:

After conceiving an idea about new PCB designs, you need to test your product quickly. PCBasic promises you rapid turnaround time for the prototype PCB assembly.

Depending on the number of pieces you order, we can guarantee a quick turnaround time of a few hours to a couple of days. The swift response gives you time to verify the accuracy of the board and venture into mass production as soon as possible.

That’s possible since we tap on the CRM, ERP, MES, and IoT management systems.

We don't just promise rapid turnaround time; PCBasic employs advanced technology in the prototype PCB assembly process. Cutting-edge technology shortens the production process without compromising the preciseness and efficiency of the work.

From the circuit design, assembly, and soldering to the testing and quality control stage, every step taps on the latest technology.

At every stage of the production process, we take stringent measures to deliver top-notch service. However, PCBasic has been in the PCB and PCBA industry for more than ten years.

Thus, during the ten years of operation, our professional team has enriched their skills and learned valuable experiences. Therefore, you can count on us for high-quality PCB prototype assembly services.

As one of the leading PCBA and PCB manufacturers, PCBasic meets the quality threshold according to ISO9001, IATF16949, and ISO13485 standards.

Before shipment of the prototype, our quality assurance team performs vital tests to verify the product.

We aim to tailor the prototype PCB assembly services to our customers' needs. Therefore, we are open, flexible, and ready to customize the production process to reflect your needs. For example, we don’t set any minimum quantity of order for the PCB prototype assembly.

Therefore, you can order a single product, ten, 100, or even more. In addition, before shipping you the product, you can place requests for specific functional tests on the prototype.

First, our team of professionals receives the Gerber design files and other vital instructions from the customer. After receiving the file, we don’t just begin the prototype PCB assembly straightaway.

Instead, we have a dedicated team that uses the advanced DFM tools to verify the functionality of the board. The board house checks on possible issues that might hinder the smooth functioning of the board.

When we notice any missing information or poor spacing of components, we consult with the customer to correct the anomaly in time. The purpose of the design and consultation stage is to identify and eliminate any potential problems that might bring about unnecessary expenses.

PCBasic has been in operation for more than 10 years. Over the years, the company has waded out unreliable suppliers.

On the contrary, we have forged strong ties with reliable manufacturers of top-quality SMT components. So, you can rest assured that we only use high-quality parts in the PCB prototype assembly services.

Although we have reliable components suppliers, we aren’t taking any chances concerning the quality of materials and components.

That’s why we have a strict, accurate, and automated incoming quality control inspection system. The automated IQC system verifies the following on the resistors, capacitors, inductors chips, and other components:

● Components quantity and model number to match the BOM list

● Broken pins, deformed or oxidized chips

● Taking random samples for testing to verify their functionality and accuracy

If the system detects any discrepancy or low-quality components, we discard and return the components.

After verifying quantity, quality, and model number to meet our threshold, the process moves onto the assembly and soldering stage. In the preliminary stage, our PCV assembly team uses the Gerber data provided by the customer to manufacture the bare printed circuit board.

After that, the prototype PCB assembly and soldering involves the steps below:

Here, we tap on the laser cutting stencil technology. That's because it's pocket-friendly and gives efficient results.

Before beginning the assembly, we have to inspect components to verify their quality and if they match the customer's specifications.

After confirming the originality of the parts, they passed on to the baking. Components baking eliminates the bubbles and thus gives efficient results. The baking time varies from component to component. For example, LED requires 4 hours, and ICs about 12 to 24 hours.

The success of this stage depends on using the right solder quality and making the perfect SMT stencil. Therefore, PCBasic uses the Alpha from Japan. Although it is slightly expensive, Alpha tin solder paste is efficient and gives superb results.

Manual picking and placement of components can be slow and straining for the eyes after working for long hours. So, at PCBasic, we use the pick and place machine JUKI from Japan. The machine fits the prototype PCB assembly service because:

● Doesn’t suffer the pressure of work like manual pick and placement by hands

● Picks and places the exact components at a faster speed

Before reflow soldering, the automatic optical inspection machine (AOI) confirms the correct placement of each component. It does that by comparing the Garber data versus the actual placement of parts. After the verification, the reflow soldering begins.

First, we set the correct reflow soldering temperature of 10 degrees. Such heat level is friendly to the components, easy to control, and thus gives optimum results. At the end of the process, the solder solidifies and the components adhere to their respective places.

Once the solder solidifies, the prototype PCB assembly process proceeds to the post-AOI stage. The post-automatic optical inspection stage checks for poorly soldered joints and shots between points.

Often mistakes arise if any movement occurs during the reflow process. Besides using the AOI machine, X-rays can also help check for faults.

The AOI machine has cameras at strategic angles to the board. By reflecting light on the board at high resolution, the machine reveals the nature of the solder joints, whether it’s poor or excellent.

Unlike annual inspection by hand, the automatic process is fast and fits large batch boards and even those with high-density components. If our team unearths any faults, they rectify them quickly. Next is cleaning of the board before proceeding to the through-hole PCB assembly.

Some multi-layered boards call for incorporating through-hole components. The whole assembly may take unique soldering styles such as:

It’s a method where each person inserts a through-hole component into a particular area. That goes on until the last person fits the last component. As noted, the process is time-consuming and tiring.

After inserting all the through-hole parts, a wave of molten solder is passed over the bottom section of the board. When that happens, all the pins sticking out get soldered. The wave soldering technique isn’t ideal for double-sided boards as it can disengage all the previously soldered components.

Before packaging and shipment of the product, it undergoes functional testing. That involves powering and feeding the prototype board with simulated signals.

The experts then note the output characteristics. If it resonates with the predetermined range, the test is successful. Usually, clients spell out the kind of test to run on the PCBA and projected output.

1) Free assembly fee for first prototype order

2) No MOQ request, you could choose the quantity you want

3) PCBasic manages your order from small volume to high volume.

3 SMT lines for prototype PCB assembly (1~10pcs), 12 hours fast turnaround PCB assembly.

1 SMT line for small volume production (11~100pcs), 24-hour fast turnaround PCB assembly.

4 SMT lines for medium volume batch production (>100pcs), 1~3 days fast turnaround PCB assembly.

We could grow from you, and enlarge your market, from prototype to batch production.

Placing an order for prototype PCB assembly is straightforward. Below are the exact steps to follow.

First, you send the Gerber files and the bill of materials about the PCB prototype assembly. Then the PCBasic uses the information to compute the price quotation for the service.

Once you receive the quotation, you confirm the order by making the appropriate payment as requested by the manufacturer. The payment signifies your commitment and thus lets the manufacturer proceed with the PCB prototype assembly process.

The next stage involves the PcBasic engineering team analyzing the PCB layout data. From the analysis, the experts can point out simple mistakes and propose changes to the customer before production commences.

Once the team of experts has analyzed and proposed the changes to the order, they send it back to the customer. When the client is satisfied and accepts the changes, the production commences.

Before shipping out the product, we will send you a sample picture. Then, you study the picture and confirm the board.

After agreeing to the sample picture, we commenced the board assembly production. After that, we follow the customer's instructions regarding the functional test on the prototype.

When the prototype PCB assembly passes the functional test, it reflects the customer's wish. So, we pack it carefully and ship the package to the client via DHL. The shipping may take about 3 to 5 days, depending on your location.

We believe in our production process and team. Thus, we offer a 1-year warranty on the prototype PCBA.

So, are you ready to start your PCB prototype project? We are here to help you from the initial point to the last stage. Make your order for as little or as much PCB prototype assembly you want.

PCBasic doesn’t put a restriction on the minimum order quantity. Besides, we promise you a free assembly fee on the initial prototype order. And did I tell you that we give you a year warranty on the prototype?

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.