Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

In the realm of electronics manufacturing, time is of the essence and efficiency is paramount, while precision is non-negotiable. Enter Turnkey PCB Assembly – a comprehensive solution that has revolutionized how businesses approach the production of printed circuit boards (PCBs). This system is not just about assembling PCBs, but also about simplifying the complex orchestration of logistics, procurement, and manufacturing into a seamless, efficient process.

Before choosing a Turnkey PCB assembly manufacturer, you should make sure that PCBA works flawlessly and make a PCB prototype. You need a trusted Partner, so about PCB assembly, in the definition of PCBasic.? Let's take a look together!

Turnkey PCB assembly involves the complete assembly process of the PCB board from start to finish, done by the PCB manufacturer. The term "turnkey" means that the project contractor handles the design, Components Sourcing, and assembly, and the project will not be handed over to the customer until the test is passed; this service of PCB manufacturers is different from just creating a bare board or connecting parts on board that need more time, and customers have to do a lot of work for board assembly.

About PCBasic

About PCBasic

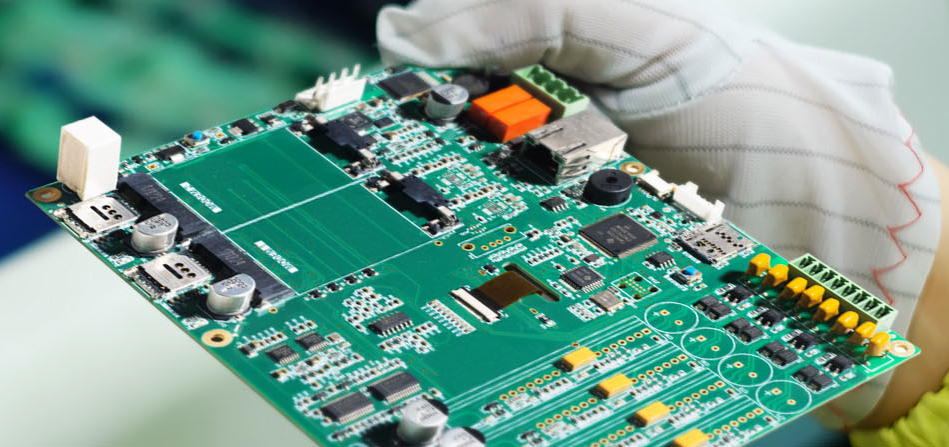

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Many PCB suppliers provide this service at reasonable prices. When someone buys PCB components individually, he has to pay shipping, making production reaction expensive. But you will use low-cost production if you have a complete turnkey assembly.

Making the board individually do all steps of PCB assembly will take more time to manage, from component sourcing to final assembly. But all actions are done on one platform if you get complete turnkey assembly. Since it reduces communication and quotation. As a result, the entire project assembly time decreases.

This process also simplifies the supply chain for businesses. There is a streamlined supply chain for enterprises. They can manage and have proper accountability for the parts location process, vendor control, and handling of the assembly process from start to finish. The one unit getting assembly services helps make project-related discussion and logistical management easy.

When a single entity is responsible for the entire PCB assembly process, it's easier to maintain consistent quality. This centralized control over the production ensures that each step meets certain standards, reducing the likelihood of errors and defects.

Turnkey PCB Assembly Process

Material is managed in the first step of turnkey PCB assembly, with the components used according to the requirements gathered. The main features are PCB boards, electronic components, and assembly materials.

After getting the components needed, manufacturing started, involving bare board creation according to design; the main steps in PCB fabrication are etching, laying, and drilling.

There are two main methods used for component assembly on manufactured boards. The first is surface mount technology or SMT, and the second is through-hole technology, or THT. Automated assembly instruments perform the SMT and THT to ensure proper and accurate component placement.

Different tests are done on the board to check the quality and measure parameters. Functional tests confirm that electronic circuits are operating according to the required parameters. During quality checking, it is found that if any defect exists at any assembly phase, it can be solved.

After clearing tests and quality measures, the board goes to the final assembly phase. Integration of the board is made up of large assemblies, connecting different components and ensuring the final product works accurately.

The finished product is accurately packed to prevent damage during transportation. The assembly services fulfill the requirement to deliver products to customs at a given time. These are transportation requirements, fulfilling the legal parameters, and fast delivery.

Selecting the appropriate partner for turnkey PCB assembly is crucial. Factors to consider include:

Get service with a high level of experience and good customer reviews about their benefits. The experienced service providers can handle any difficulty and the required parameters of the final assembly.

Before getting the services of any manufacturers, check their capabilities and skills to handle that project. Get their scale and operating size details to confirm they can fulfill your project demands. Also, check if the technical features and instruments used for project creation are the latest or older.

For PCB assembly, quality is considered the main factor. Ensure that manufacturers have required certifications like ISO 9001. If that company provides all the necessary accreditation, it means they fulfill the required standards and quality factors.

They also have a proper communication platform for customers. So they can update you regularly about your products. With customer support, users can get details at any project phase and, if needed, ask to make changes.

PCBasic, as a PCBA factory with more than ten years of experience, has developed a series of intelligent production management systems for better turnkey PCB assembly quality. Turnkey PCBA manufacturing will give your project a faster turnaround time.

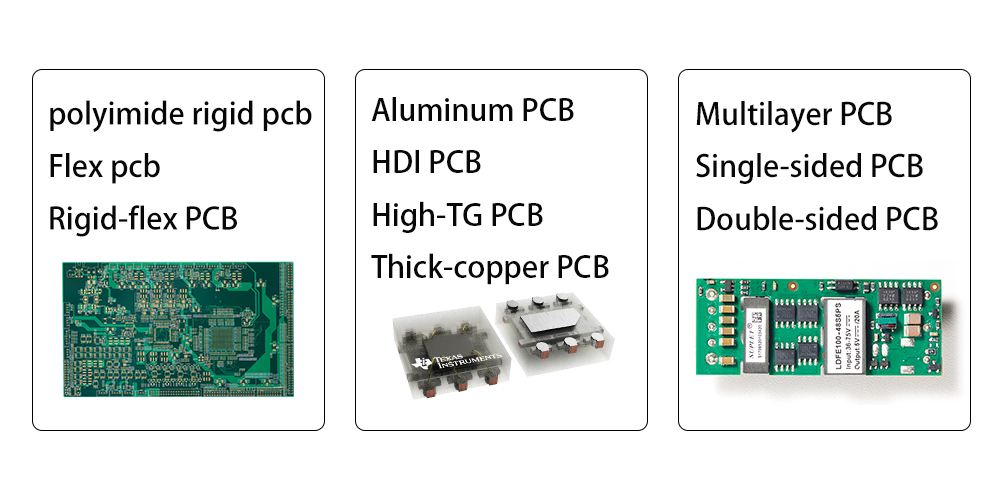

• Layers: single-sided, double-sided, and multi-layer circuit boards.

• Material properties: FPC, PCB, FPCB.

• Downstream applications: industrial control boards, medical instrument boards, aerospace, power boards, smart home boards, etc.

• PCB surface treatment: Thick-copper PCB, Rogers PCB, Aluminum Pcb, etc.

• Specially printed boards: glass substrates, ceramic substrates, etc.

We provide a full range of turnkey pcb assembly services, you also don't need to worry about the cost increase, we have long-term high-quality cooperation with many suppliers, and have a price advantage when purchasing components, so we can guarantee low price and high quality!

During the entire turnkey Pcb assembly process, we will keep in close contact with you, and if there is any problem, we will confirm with you as soon as possible that the production will continue.

In the PCB assembly project, choosing a professional and excellent manufacturer is an extremely important part.

We have been efficiently providing high-quality circuit boards and high-quality, intelligent electronic turnkey PCB assembly services to customers all over the world from Shenzhen, China.

PCBasic has approximately 200 employees. As a leader in mid-to-high-end rapid

production in the field of turnkey electronic PCB assembly. We can offer

state-of-the-art and limitless capabilities for your prototype PCB or PCB assembly. Speed, technology, service, and quality are the core concepts

that PCBasic has always adhered to.

Fast Quote

Competitive Pricing

PCBasic has accumulated more than 15 years of experience in turnkey Pcba, and has long-term cooperation with many suppliers, so we have a relatively intuitive price advantage.

You only need to submit the information, we will provide you with the most competitive price within a few minutes.

Choose PCBasic, we offer you the best turnkey electronics service.

15+ years experience

Self-developed MES System

We have been developing intelligent systems for turnkey pcb assembly since 2016, and now we self-developed PCB Assembly MES system, with layer-by-layer quality control and confirmation, eliminates defects from the source.

We have also developed Intelligent material racks, and First-piece tester, etc.As long as it is helpful to turnkey pcb assembly, we will take the time to study it.

As shown in the figure, this is our First-piece tester, import the bom table and material coordinates of the circuit board, and then the corresponding test program can be generated.

100% Quality Assurance

100% Quality Assurance

Regarding quality certification, PCBasic has ISO9001/IATF16949/ISO13485 certification.

We control the quality very strictly, and make reasonable use of our MES system for control. From the expected to the delivery of the test, it is closely linked and strictly controlled.

As shown on the right, this is the push-to-talk button on our pick and place machine. Press the button, and the corresponding IPQC personnel's wristband will respond and vibrate so that the quality control of the pcb assembly can be carried out the first time.

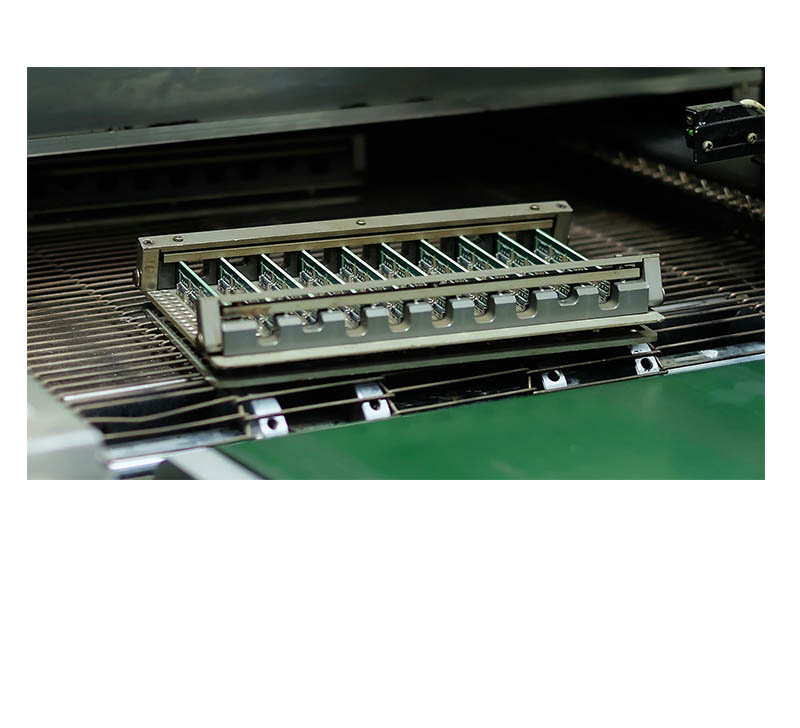

We have 8 SMT production lines, including sample lines and high-volume lines.

From proofing to mass production, we can do it for you.

PCBasic will always accompany you and provide you with turnkey PCBA services.

The main application use cases of PCBasic's PCB/PCBA services are Automotive, Medical, Military, IOT, Smart Home, industry Control, Aerospace etc.

Seeing this, are you curious, what is the "MES" system, and what does it do?

This is our self-developed intelligent system, because we attach great importance to the quality issues in the PCBA process and are also committed to continuous innovation. Obviously, in the era of big data, having an intelligent production system is the best choice.

The MES system can bring together all the data in our production process so that we can complete the PCB assembly more efficiently and with high quality. The MES system enables real-time data viewing, and for PCBasic, real-time data access not only drives board production but also drives the entire development process.

We continue to invest in technology research and development and have successfully developed a series of intelligent production management systems, which enable our PCB assembly to improve efficiency and quality, With self-developed MES systems, sample patch systems, intelligent material rack, SMT fault detection system, advanced intelligent ESD electrostatic protection systems and LCR incoming inspection systems.

We have a dedicated stencil mesh department, no need to outsource to other manufacturers, we can make the suitable steel mesh according to your project. Our engineers will make the stencil program according to the form you give, and then use the stencil laser machine to make the stencil.

Product testing is required in the PCBA process, which is the control of the quality of PCBA products. During product testing, sometimes a jig is needed, and the jig can help testers work better.

In order to provide you with a quick quotation service, please provide us with the BOM and Gerber of the project.

The BOM should include Supplier and Part, Reference Designator, Package Type, etc. Gerber is best to send us all the Gerber files of your CAD program.

1. For PCB: indicate quantity, Gerber file technical requirements(material, size, copper thickness, board thickness, surface finish treatment etc).

If you're ready to produce your design, try our quote tool to upload your BOM file and Gerber. If you want to know more about PCB Assembly industry information, contact us online or by email in the lower right corner.

Regardless of BOM file size, you can get a complete turnkey quote in no time.

Turnkey PCBA assembly is an advancement in the circuit board assembly industry.

We leverage all of our manufacturing and supply chain expertise to bring you a complete one-stop service.

Turnkey PCB Assembly is the best service for electronic businesses that want to develop and grow their electronic manufacturing techniques. It helps reduce costs and increases efficiency by using fewer resources on one platform and having quality products. Since it involved the manufacturer's discussion with different electronic production suppliers and provided the required project to users. The selection of the correct assembly service provider at the start of the design process ensures that error-free board assembly is delivered at a given time. Working on the DFM review and testing stages of turnkey minimizes the expenses of related products.

You are welcome to visit our factory anytime, our address is Floor 2-3, Building E, Jianshi Industrial Park, Huangpu Road 52#, Xinqiao Street, Baoan District, Shenzhen, China. If you are inconvenient to visit the site due to various circumstances, we will also provide you with an online video introduction at any time.

PCBasic: We provide professional turnkey PCB assembly service, including PCB fabrication, components purchase, SMT/DIP assembly, product testing, Three-proof paint printing, and other value-added services.

PCBasic: We have a self-developed MES system and First-piece tester, which makes us a smart factory.

PCBasic: We will provide the most affordable price and hope that we can become a long-term cooperative partner.

PCBasic: Of course, our MES system will update the production data in real-time, and you can check it at any time as long as you need it.

PCBasic: Our factory is

located in Building E, Jianshi Industrial Park, Shajing, Shenzhen, Guangdong,

China. Welcome to visit us.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.