Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Solid State Drive (SSD) PCB

In the era of high-speed digital storage, SSDs have revolutionized the storage industry with outstanding performance and reliability. At the heart of every SSD, the SSD PCB hosts and connects all key electronic components for data storage, transmission and management.

In this blog post, let’s take a deeper look at the definition of SSD PCBs, its main components, application advantages, while comparing SSD PCBs with HDD PCBs. At the same time, introduce the professional SSD PCB manufacturing and assembly services provided by PCBasic.

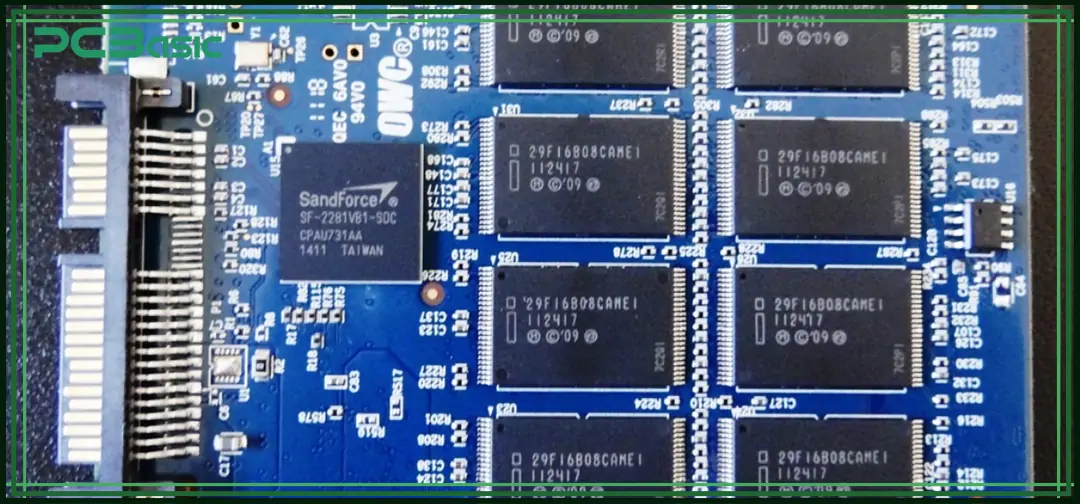

The SSD PCB, or printed circuit board of the solid state driver, is the most core circuit board inside the SSD. It is like the brain and nervous system of the SSD, which is responsible for mounting all the key components, such as the NAND flash memory chip (where the data is stored), the master chip (which controls how the data is read and written), on a board and connected by circuits so that they can work together.

An SSD PCB is mounted with a number of key electronic components that work together as a team, allowing the SSD to read and write data quickly and save files for a long time. Each component has its own responsibility, and the better they work together, the better the SSD will perform. The main components include:

• NAND Flash Memory Chips:

This is where the SSD is really used to store data. All photos, videos, and files are stored in these chips, which is equivalent to the SSD's "warehouse."

• SSD Controller:

Like the "brain" of the SSD, it is responsible for arranging how data is written, where it is read from, how to fix errors, and how to communicate data with the computer. Without it, other chips can't work together.

• DRAM Cache (optional):

This is a fast temporary storage area, equivalent to the SSD's "notepad". It is used to prepare data in advance or temporarily save the information to be processed, which can greatly improve the reading speed.

• Power Management ICs:

Its role is to reasonably distribute the power supply provided by the computer to each component on the SSD PCB, to ensure that each part can run stably, and will not cause data errors or damage due to voltage problems.

• Capacitors and Resistors:

These small devices, although humble, are very important in the circuit. They are responsible for keeping the signal stable and clear, and avoid errors when data transmission.

These components are mounted and soldered to the SSD PCB by high-precision machines, compact arrangement, scientific structure, and finally form a powerful and compact SSD core circuit board.

Although both SSDs and HDDs contain circuit boards, their designs and functions are very different. SSD PCBs are optimized for high-speed storage interfaces and compact construction, while HDD PCBs are used to drive components such as motors and mechanical heads.

Let’s compare their differences in a table:

|

Feature |

SSD PCB |

HDD PCB |

|

Speed |

Significantly faster |

Slower |

|

Components |

NAND flash, controller, cache |

Motor controller, read/write head driver |

|

Durability |

No moving parts |

Prone to mechanical failure |

|

Power Use |

Lower |

Higher |

PCBasic specializes in high-quality PCB manufacturing and PCBA assembly for a wide variety of products in small to medium batches, with extensive experience and mature technical processes particularly in high-speed storage products such as SSDs. We are committed to providing stable, efficient, and customized one-stop solutions for the rapidly evolving solid-state storage industry, helping clients bring products to market quickly and enhance their competitiveness.

Our Core Capabilities Include:

• Professional SSD PCB Design and Layout Optimization

We offer multilayer board designs with high-speed signal integrity for NAND flash, SSD controllers, cache, power management chips, and other critical components. Our expertise includes EMI/EMC optimization, thermal management, and high-density interconnect (HDI) layout—perfect for thin and high-performance SSDs.

• Advanced Surface Mount Technology (SMT) Capabilities

Equipped with 9 fully automated SMT lines, including high-speed pick-and-place machines, fully automatic stencil printers, and 10-zone reflow ovens. We support 01005, BGA, LGA, QFN, and other complex packages, ensuring precise placement and soldering for SSD PCBs of all sizes and structures.

• Stringent Quality Control System

Our quality assurance process incorporates next-generation flying probe testers, inline AOI, X-ray inspection systems, and functional testing. We are certified to ISO 9001, ISO 14001, ISO 45001, and IATF 16949, ensuring consistent and reliable SSD PCB deliveries that meet the highest industry standards.

• Agile Delivery and Engineering Support

From prototype development and small-volume trial runs to medium and high-volume production, we offer full-process services ideal for SSD products with fast-paced development cycles. Our professional FAE team provides BOM optimization, DFM (Design for Manufacturability) analysis, and electrical test consulting, helping reduce development time.

Our Facility and Production Highlights:

• Over 22,000㎡ of factory space, located in Shenzhen and Huizhou with convenient logistics;

• A team of 500+ experienced staff and efficient production management;

• Annual output of millions of units, serving clients across 30+ countries and regions;

• Support for customer-supplied materials or full turnkey services;

• All SSD PCB products come with complete test reports, traceable barcodes, and packaging labels upon delivery.

Clients & Application Fields:

Our SSD PCB and PCBA services are widely used in:

• Consumer electronics (e.g., laptop SSDs, portable solid-state drives)

• Industrial storage devices (e.g., data loggers, embedded systems)

• Enterprise servers and data centers

• Aerospace, military, and other specialized storage applications

We’ve built long-term partnerships with leading SSD module manufacturers, OEM device makers, and industrial solution providers—earning strong trust and recognition across the industry.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.