Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Overview of PCB Slots

Modern electronics are transforming with each passing day, and thus, the demand for efficient printed circuit boards (PCBs) is increasing rapidly. Many advanced PCB technologies, such as flexible PCBs, rigid-flex PCBs, high-density interconnect PCBs, are bridging the gap to fill the advanced requirements of modern electronic designs.

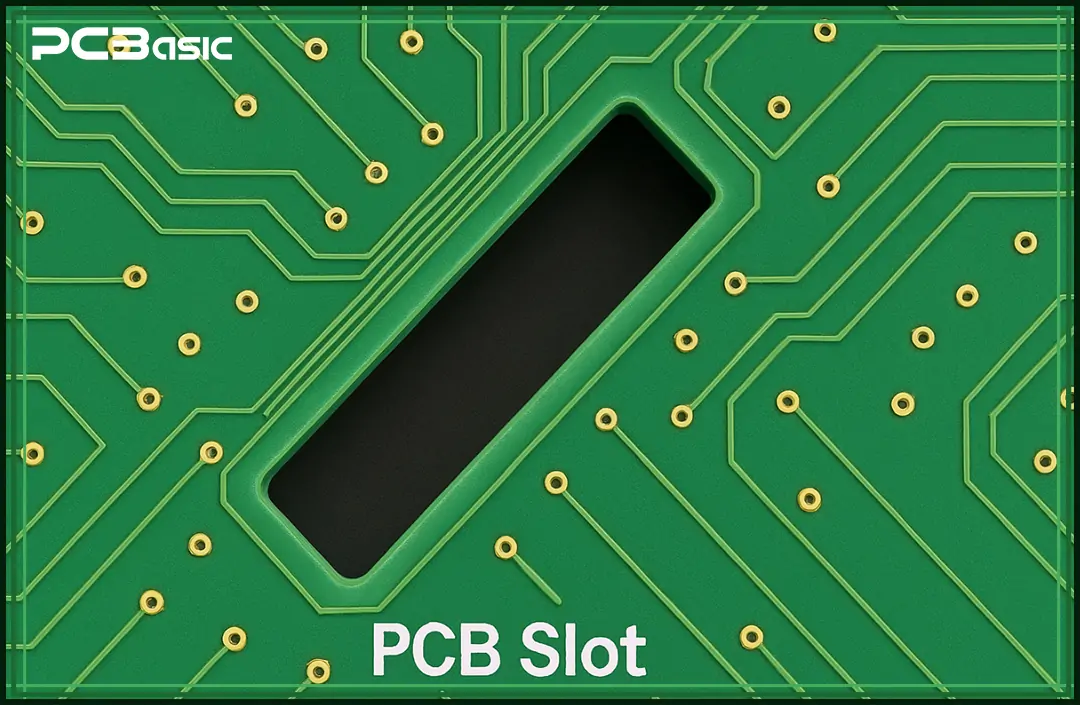

PCB Slots play a critical role by accommodating the design requirements of non-standard lead shapes and providing greater mechanical stability. This article provides an in-depth overview of slot PCB, its types, applications, and how design engineers can optimize slot PCB layout using Eagle software.

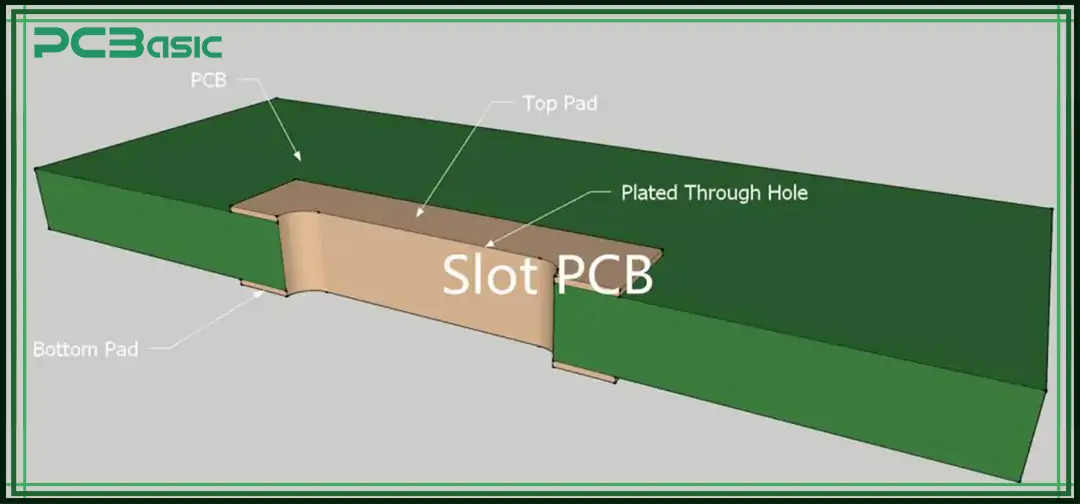

PCB slots are different from standard circular holes in the circuit board. PCB slots are non-circular holes that are used to accommodate specific components with non-standard lead shapes or when greater mechanical stability is required. Unlike standard drilled holes, PCB slots are customized for specific rectangular or irregular-shaped leads. PCB slots can either be plated or non-plated, depending on the design requirement. These PCB slots are also used to provide electrical isolation, greater mechanical stability, and signal integrity, and are sometimes used to prevent circuit failure after continuous operation.

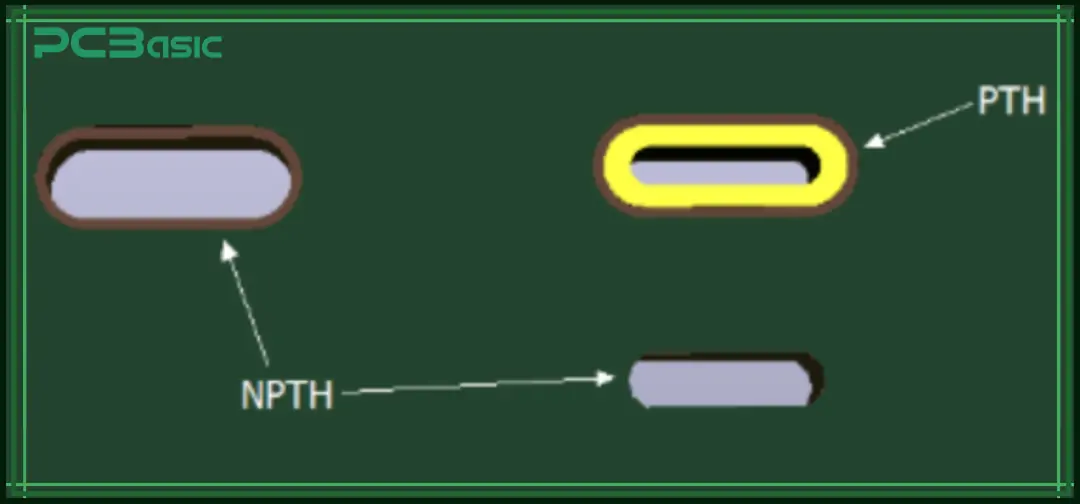

Depending on the design requirement, PCB slots are broadly categorized into plated and non-plated PCB slots.

Plated PCB slots are a type of slots that have conductive copper plating on both the top and bottom layers of the circuit board. Plated slots are mainly used in applications where a PCB needs to maintain electrical connection with non-circular or irregular shape leads. Plated slots are common in multilayer printed circuit boards.

• Why do We Need a Plated PCB Slot in Our Design?

Plated slots become essential where electrical connectivity and mechanical stability are required for non-circular leads.

Non-plated slots are a type of slot that does not have conductive plating, and they do not serve to maintain the electrical connectivity. These slots are primarily used where mechanical separation and electrical isolation are required. Non-plated slots are commonly larger compared to plated slots, resulting in better thermal distribution across the board.

• Why Do We Need Non-Plated PCB Slots in Our Design?

Non-plated slots should be an important design consideration, where mechanical separation, which can contribute to improved thermal performance in specific designs.

Plated and non-plated slots play a vital role in printed circuit board design. These are used in applications where electrical connectivity and mechanical stability are required.

• Electrical Isolation: PCB slots are used in high-voltage applications where slots are made to ensure component-to-component isolation. This is important to prevent a component from getting short-circuited.

• Consumer Electronics: PCB slots are used in consumer electronics, such as gaming consoles and network equipment circuit boards, to provide better thermal management and electrical isolation.

• Power Electronics: PCB slots are commonly used in large leaded components for stable electrical connection. They are also used in high-power relays and switches to provide a reliable connection for high-current switching devices.

• Radio Frequency & High-Speed Circuits: PCB slots play a critical role in RF circuits by minimizing the impedance mismatch and improving signal integrity.

• Mechanical Support: Non-plated slots are used to enhance mechanical stability and structural integrity.

When designing plated slots in PCB, it is important to follow some good practices to achieve optimal electrical connectivity and enhanced mechanical stability.

1. Manufacturer Selection: When designing a PCB slot, choose a PCBA manufacturer that can easily accommodate the plated slot design. PCBasic is a leading PCBA manufacturer and can accommodate any PCB slot design. Please, consult with PCBasic for your specific PCB slot design.

2. Accurately Define Slot Dimensions: PCB slot dimensions play a critical role in determining the optimal electrical connectivity and mechanical stability for your circuit board. It is therefore important to accurately define plated slot dimensions to ensure your PCB design functions accurately.

3. PCB Slot Alignment: Accurately align and position the PCB slot in your design. It is important because any misalignment can lead to poor electrical connectivity and mechanical failure.

4. Design Rule Checks: It is always recommended to check Design Rule Check (DRC) using professional PCB designing software such as Eagle to avoid manufacturing issues.

5. Ensure Proper Copper Plating: Plated slots are used for electrical connectivity, and improper copper plating in slots leads to poor electrical connectivity. To prevent such failures, ensure copper plating is uniform throughout the slot.

PCB slot lengths vary depending on the PCB design requirement and manufacturer limitations. However, a common question that arises frequently is “What is the smallest PCB slot possible”?

Various factors influence the minimum PCB slot size, including PCB material, Manufacturer limitations, and type of slot. However, there is a minimum practical size for a PCB slot taht is between 0.2mm and 0.5mm. Again, the exact minimum is dependent on the design requirement and the manufacturer's capabilities. In the printed circuit board industry commonly 0.2mm is considered the smallest PCB slot. In the PCB industry, typical minimum slot (length, width, depth) values are mentioned below.

|

Minimum Slot Length |

Minimum Slot Width |

Minimum Slot Depth |

|

0.5mm |

0.2mm |

0.2mm (dependent on the thickness of the PCB material) |

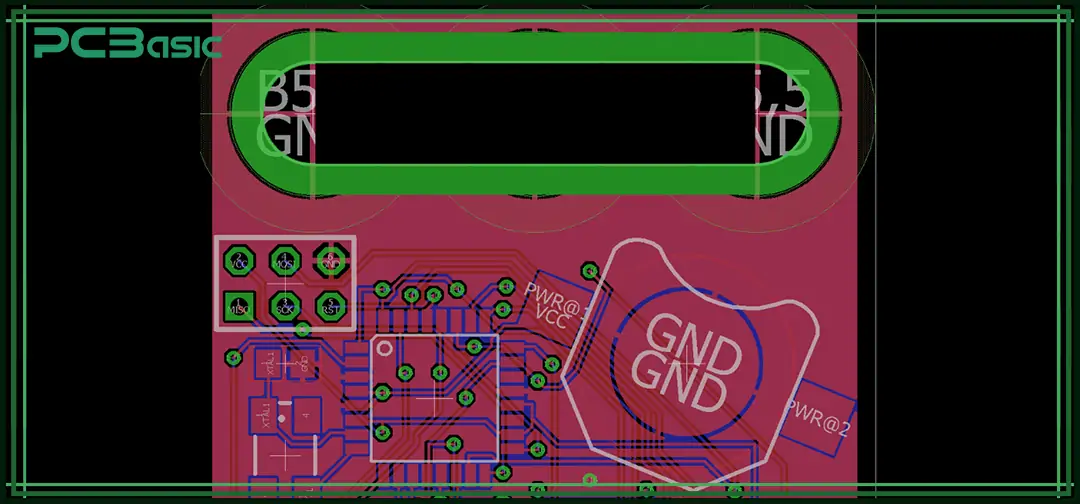

Eagle is a professional PCB designing software platform that enables engineers to design and develop modern electronic circuit boards. To create a PCB slot using Eagle software, follow the below mentioned steps below.

1. Open your PCB design in Eagle software and ensure that the PCB project is opened in the board layout editor.

2. To access the PCB slot tool, select the milling layer in your Eagle software. In the layer setting, make the milling layer visible.

3. Now, draw the desired slot shape using the polygon. For a rectangular slot, you can use a rectangular tool. Enter the desired slot width, height, and depth. Make sure to enter accurate dimensions to prevent any design failures.

4. Now, define a keep-out area to prevent routing copper traces through the slot.

5. It is time to convert your PCB slot into its actual shape. This is done by the cutout tool in Eagle software. Edges of slots are crucial, and it is important to align slot edges with the component footprint.

6. Use the Grid and Measurement Tool to make sure that the slot dimensions are accurate and as per the design requirement.

7. Go to the Tools and choose DRC. Run a Design Rule Check (DRC), which will ensure that the PCB slot is under the PCB design constraints. If you encounter any errors, make sure to resolve them before proceeding further.

8. At this point, the PCB slot is designed, and it's time to generate the Gerber File for manufacturing. You can access the Gerber Files tool by going to the CAM processor and then selecting the export Gerber. Do not forget to include the milling layer in your Gerber files.

9. Get the Gerber files and share them with your intended PCBA manufacturer. PCBasic is a leading PCB manufacturer that accurately handles and manufactures your PCB slot design.

PCB slot is an important feature in printed circuit design because it plays a critical role in maintaining electrical connectivity, providing electrical isolation, and enhancing mechanical stability. PCB slots are mostly used in situations where standard drilled holes are not suitable and non-circular holes are required for accommodating non-standard lead shapes. PCB slots are either plated or non-plated.

Plated slots have conductive plating and are thus used for maintaining electrical connectivity. On the other hand, non-plated slots do not have conductive plating and are therefore used for reducing the mechanical stress across the circuit board. Understanding PCB slots, their types, and applications is critical for design engineers to accurately design PCB slots.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.