Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Overview of a PCB Module

In modern electronic product design, compactness, efficiency and high performance have become the basic requirements. The core of achieving these key indicators lies in the application of PCB modules.

As the "heart" of electronic systems, PCB modules are widely used in smartphones, new energy vehicles, industrial automation equipment, and many other fields.

So, what exactly is a PCB module? Why does it occupy such an important position in modern electronic devices?

A PCB module refers to a fully assembled and functionally tested circuit board unit that has all the hardware circuits required to perform a specific function. It is on the basis of a bare PCB, which includes only circuit traces and substrate material.

Through the SMT and insert DIP process, the various electronic components such as resistors, capacitors and connectors are mounted on it. After assembly, the module undergoes rigorous testing and verification to ensure that it can operate independently and deliver stable performance.

PCB module is a fully functional, plug-and-play system unit. Engineers or product developers only need to integrate into the overall system, and there is no need for secondary development of the functional unit. This modular design method not only greatly reduces the circuit design, schematic drawing, component selection, soldering testing and other cumbersome processes, but also effectively reduces the incidence of development errors and improves the reliability and consistency of products.

PCB modules have several key characteristics that make them valuable in electronics manufacturing and product development:

• Compact Design:

Every PCB module is designed with size optimization in mind. Through reasonable layout of circuits and components, the entire module is as small as possible, which is easy to be embedded in various terminal equipment. This compact design not only saves space inside the device, but also helps to enhance the overall design's beauty and cleanliness.

• Function-Specific:

Each PCB module is designed to perform a specific function. For example, there are modules dedicated to power conversion, which are responsible for converting voltage from one level to another. Because the design focuses on a single task, the performance of modules is often more stable and efficient, suitable for critical roles in complex systems.

• Time-Saving:

Traditional development requires multiple steps: circuit design, component selection, PCB layout, soldering, and testing. This process is time-consuming and error-prone. By using a well-developed PCB module, developers can skip most of these steps. They only need to connect the module into their system and handle basic software integration. This significantly reduces development time, accelerates prototype verification, and shortens time-to-market, making it an efficient solution for product teams.

There are many types of PCB Modules available on the market today, each designed to meet specific application needs.

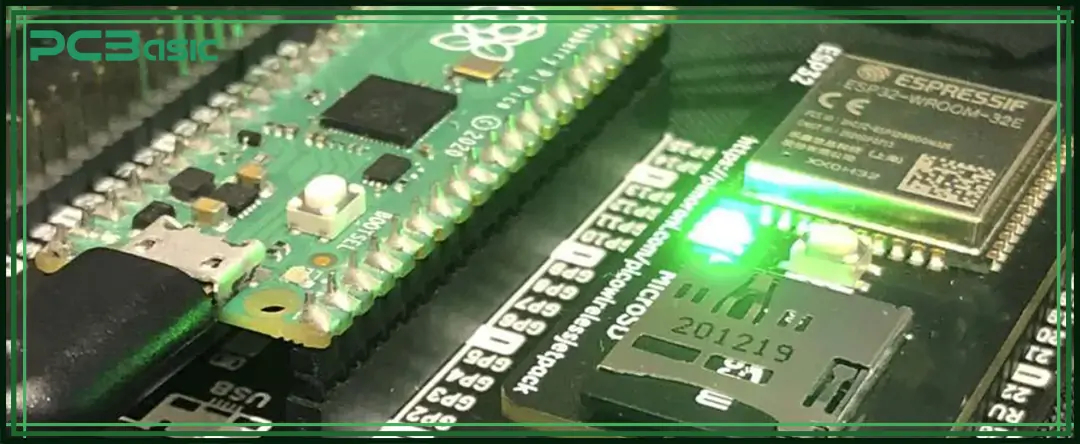

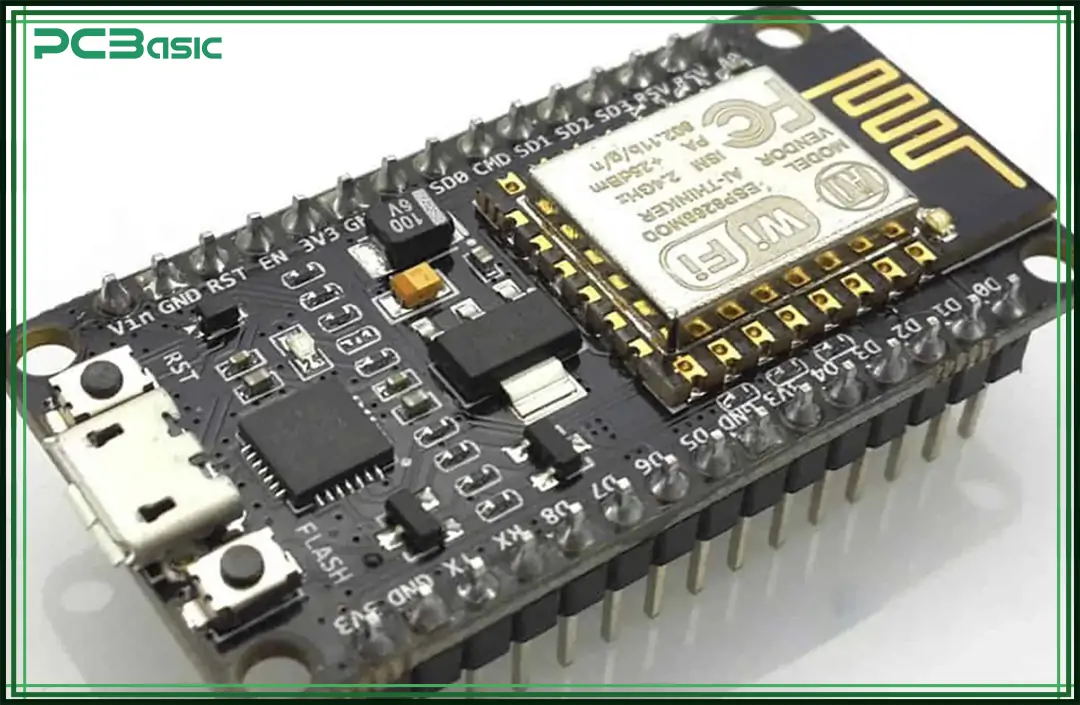

• Wi-Fi Modules:

The Wi-Fi module is a kind of PCB module that integrates wireless communication chip, RF circuit and antenna. It is widely used in smart home devices, remote monitoring systems, wearable devices and others. By connecting via standard interfaces such as UART or SPl, devices can easily join a local network or access the internet for remote data transmission and control.

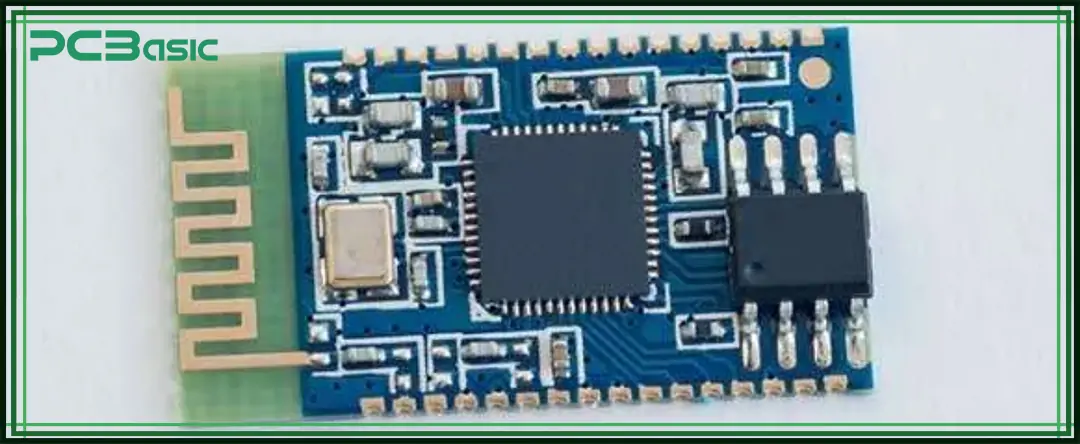

• Bluetooth Modules:

Bluetooth modules are designed for short-distance data transmission between devices, making them ideal for smart wristbands, wireless earphones, remote controllers, and more. These modules typically contain a Bluetooth chip, antenna, and protocol stack, allowing developers to implement pairing, connection, and data transfer via simple serial communication.

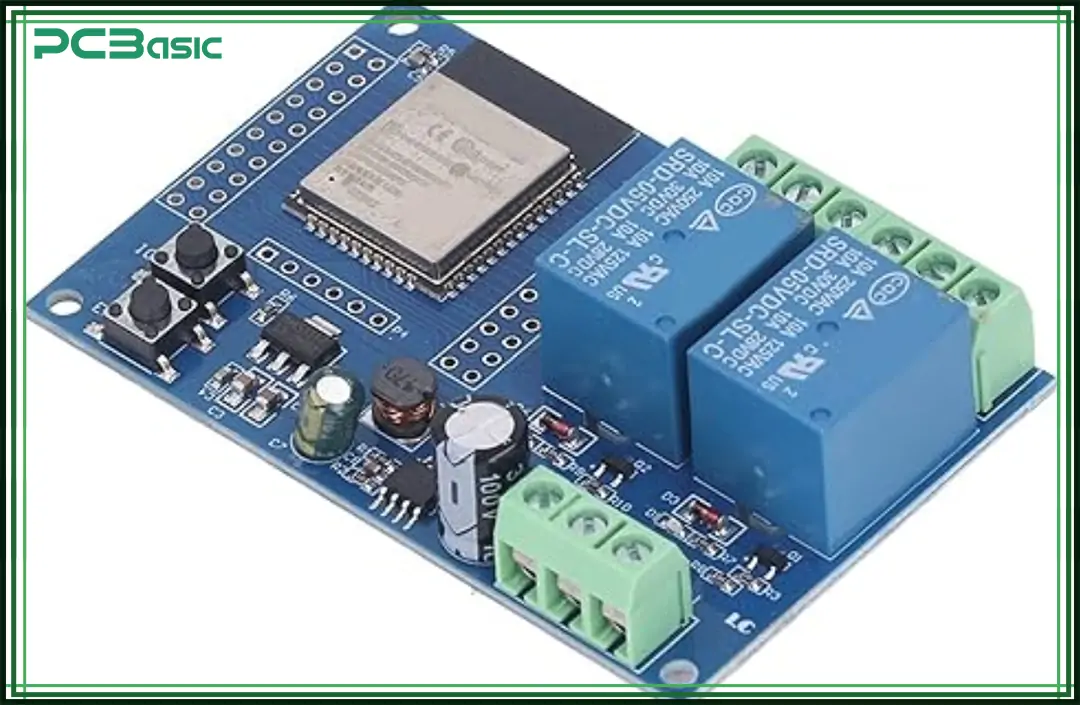

• Power Modules:

Power modules are used to convert input voltage into a stable output voltage, ensuring reliable operation of the overall system. Common types include DC-DC buck converters, boost converters, and LDO regulators. These modules integrate inductors, capacitors, control ICs, and protection circuits, eliminating the need for engineers to design complex power sections themselves. They are especially suitable for applications requiring high precision and stability in power supply.

• Sensor Modules:

Sensor modules incorporate a variety of sensors for detecting physical, chemical, or biological changes—such as temperature, humidity, pressure, acceleration, light, or gas concentration. These modules often include signal conditioning circuits and communication interfaces (I2C, SPI, UART), making it easy to read and process data. They are widely used in environmental monitoring, wearable devices, industrial control systems, and smart agriculture.

• Motor Driver Modules:

Motor driver modules allow control over motor operations such as start/stop, direction, and speed adjustment based on commands from a main controller. They typically include driver ICs, power inputs, and PWM signal inputs. These modules are essential in applications like robotics, 3D printers, electronic locks, and robotic arms, offering ease of use and reliable performance in automation projects.

Whether you're developing a simple smart home appliance or designing a complex industrial control system, there is a suitable PCB module available on the market to meet your functional needs. These ready-to-use modules significantly speed up prototyping and mass production.

In the product development stage, the use of PCB modules has significant advantages, not only to improve development efficiency, but also to effectively control costs and risks.

• Reduced Time to Market:

Since PCB modules come pre-assembled with all components soldered and fully tested before shipment, users can immediately integrate them into their systems. This eliminates the need for time-consuming in-house circuit design, assembly, and testing of individual PCBs.

• Lower Risk:

Using mature PCB Modules means that most of the critical circuitry has already been professionally designed and tested by the supplier. This significantly reduces the chances of failures caused by incomplete designs or poor soldering.

• Standardization:

Many PCB modules follow standard form factors and interface protocols, making it easy to connect with other modules or mainboards without customization.

• Cost-Effective:

In large-scale production, using PCB Modules significantly reduces the time and resources needed for in-house R&D and testing.

PCB modules are subversive in the development of electronic products. With their compact design, exclusive features and time-saving features, PCB modules have been used in a wide variety of industries. From smart devices to industrial controls to embedded systems, choosing the right PCB module can not only simplify the development process but also improve product stability and speed of time to market.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.