Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Top 5 Leading Flex PCB Assembly Manufacturers

With the rapid development of science and technology, electronic products are evolving in the direction of miniaturization, lightweight and high performance. For example, the mobile phones and electronic watches we usually use are developing in the direction of smaller and thinner. As these electronic devices, whether smartphones, wearables, medical devices or automotive electronics, get smaller and smaller, the size, performance and layout requirements of their internal circuit boards become higher and higher.

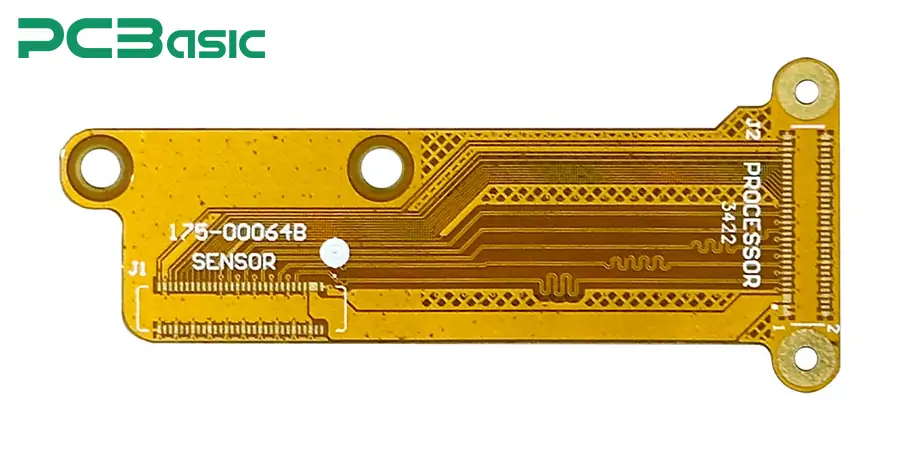

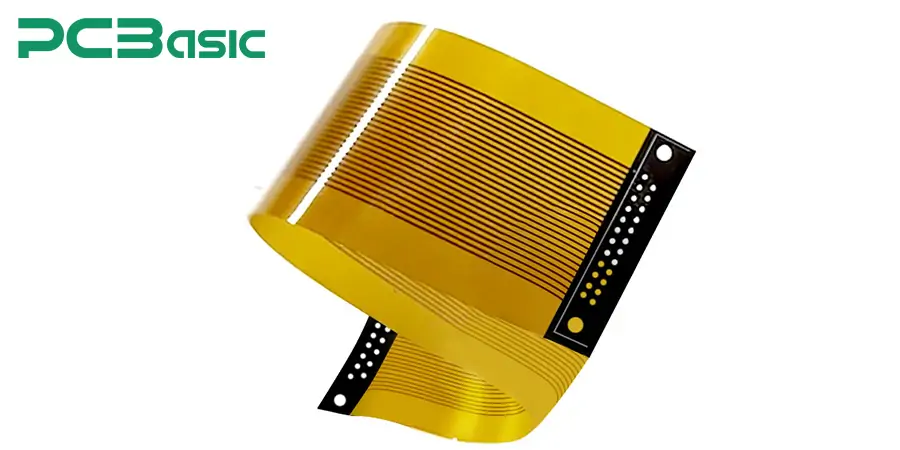

Then, in order to meet these needs (complex circuit design and space constraints of compact devices), flex PCB appeared. Flex PCB Assembly has become an important breakthrough in the electronics industry. Flex PCB can not only bend, fold, but also fit a variety of irregular structures. The emergence of flexible PCBs with such characteristics greatly improves the freedom of circuit layout and the flexibility of product design.

In this article, I will discuss some knowledge about flex PCB assembly and recommend five excellent and leading flex PCB assembly manufacturers for you. They can provide excellent flexible circuit assembly, flex PCB SMT assembly, flex assembly and other services.

Flex PCB assembly refers to the process of installing electronic components on a flex PCB. Unlike traditional rigid PCBs, flexible PCBs are designed to bend and fold, and can adapt to small spaces or application scenarios that require dynamic movement. The flexible circuit assembly process is ideal for compact designs, enabling higher component density, improved performance and increased durability. These characteristics of flexible PCB assembly make it play an important role in industries such as aerospace, medical and automotive.

Good bending: The "flexibility" of flex PCB is named for its excellent flexible design, which can bend and has a good space limitation adaptability, especially suitable for micro and small equipment.

Space saving: with the above article, the flexible PCB can save space, which reduces the complexity of traditional wiring, and effectively reduces the volume of the equipment.

Reduced probability of failure: Because flexible circuit assembly reduces the use of welds and connectors, potential points of failure are reduced.

Flex PCB SMT assembly plays a key role in improving board performance, increasing production efficiency and reducing manufacturing costs. Flex PCB SMT assembly enables precise component installation on flexible PCBs to improve product performance and manufacturing efficiency, and:

Higher electrical performance

Flexible PCB SMT assembly uses surface mount technology (SMT) to mount components directly to the PCB surface. This method shortens the signal transmission path and reduces signal delay and electromagnetic interference (EMI), significantly improving electrical performance.

Better thermal management

Because flexible PCBs use thinner substrates, the heat dissipation efficiency is better than that of traditional rigid PCB, especially in devices with high heat dissipation requirements (such as LED lighting and smart wearable devices).

Higher component density

Flexible PCB SMT assembly supports smaller component sizes (such as 01005, 0201 packages) and tighter component layouts, which can meet the development trend of miniaturization and lightweight electronics.

Flexible bending to save space

Flex PCB can be bent and folded according to the equipment structure to achieve three-dimensional wiring, make full use of space, suitable for small or irregular installation areas. This characteristic makes it widely used in medical devices, automotive electronics, wearable devices and other compact electronic products.

Optimize material utilization

There is no need to drill holes on the PCB in the process of flex PCB SMT assembly, which reduces the waste of materials in the drilling and welding process and saves production costs.

Next, I will introduce the top 5 flex PCB assembly manufacturers, each of which has its own advantages:

|

Manufacturer |

Key Strengths |

Application Areas |

SMT Technology |

|

Unimicron Technology |

High-performance Flex Board solutions |

5G, Automotive, Medical Devices |

Advanced SMT ensures precise soldering |

|

TTM Technologies |

Strict quality control for reliable products |

Aerospace, Defense, Communications |

Precise SMT for high-end equipment |

|

Zhen Ding Technology |

High-density Flex Circuit Assembly for complex layouts |

Smartphones, IoT, Wearables |

Professional SMT for intricate designs |

|

Simmtech |

Focus on signal stability and high-frequency applications |

Semiconductors, Data Servers, High-frequency Devices |

Advanced SMT ensures stable performance |

|

PCBasic |

Cost-effective solutions with efficient SMT processes; flexible production scaling and fast delivery |

Consumer Electronics, Industrial Control, Medical Devices |

Precision SMT improves soldering quality and reduces lead times |

1. Unimicron Electronics

As the world's leading flexible PCB manufacturer, Unimicron is focused on delivering high performance flex board assembly solutions. Unimicron has:

Flex PCB SMT Assembly: Unimicron uses advanced automation equipment with high precision operation.

Professional Flex PCB Design for Assembly Guide: the design process is constantly optimized according to this guide.

Rich experience in flex PCB cost control: meet the needs of large-scale production.

Unimicron's flex Assembly solutions are widely used in 5G, automotive electronics and medical devices.

2. TTM Technologies

TTM Technologies is a leading flex circuit assembly provider serving a diverse range of industries. Its advantages include:

High precision flex PCB SMT assembly for aerospace and defense systems.

Professional flex PCB Design for Assembly Guide to help customers optimize circuit design.

An efficient manufacturing process that reduces flex PCB cost and ensures high quality standards.

TTM Technologies is known for its rigorous quality inspection methods to ensure excellent product reliability.

3. Zhen Ding Technology Holding Limited

As the world's top flexible PCB manufacturer, Zhen Ding has the following advantages:

Advanced flex PCB SMT assembly technology for high density integration.

Dedicated flex circuit assembly solutions for the smartphone, wearable devices and Internet of Things (IoT) industries.

Focuses on controlling flex PCB cost by optimizing the process to ensure high cost performance.

Zhen Ding has always been committed to innovation, ensuring that the flexible circuit assembly of complex circuit boards is seamless.

4. Simmtech

As a leading flexible PCB manufacturer, Simmtech focuses on providing comprehensive flex circuit assembly services for the semiconductor and data server markets. Its advantages include:

Advanced flex PCB SMT assembly technology to improve circuit board performance.

A professional flex PCB design for assembly guide to optimize circuit layout and reduce error rates.

With effective cost control strategy in mass production, further reduce the cost of flex PCB.

Simmtech's solutions are particularly suitable for equipment requiring signal stability and high frequency performance.

5. PCBasic

As a trusted flexible PCB manufacturer, PCBasic is focused on providing cost-effective flex PCB assembly solutions. Its advantages include:

Affordable flexible circuit assembly services to meet production needs of all sizes.

The complete flex PCB design for Assembly Guide to ensure optimal circuit layout.

Efficient and intelligent SMT process to minimize flex PCB cost and improve production efficiency.

Flex board assembly expertise for complex and compact designs.

With its advanced manufacturing technology, PCBasic is a trusted partner for many customers around the world.

How to choose a reliable flexible PCB manufacturer? The following points are for reference.

1. Look at experience

Excellent flexible PCB manufacturers should have a wealth of flex PCB production experience, they can handle complex circuit design and difficult projects such as: multi-layer flexible PCB, rigid-flex PCB, etc.

2. Look at supply chain management

The quality of flexible PCB must be high by high-quality substrate, such as PI, PET and so on. Therefore, a qualified flex PCB manufacturer should have a stable material supply chain, while supporting customers to select the right materials to optimize costs.

3. Look at technical strength

Flexible PCB is light and strong bending, which makes its production process very demanding. Therefore, an ideal flexible PCB manufacturer should have precision laser cutting, precision drilling, line etching and laminating processes to ensure the dimensional accuracy and electrical conductivity of each flex PCB.

4. Look at testing and quality control

Since flexible PCBs are often used in high-reliability products (such as medical devices, automotive electronics, smart wearable devices, etc.), rigorous quality testing is particularly critical. High-quality flexible PCB manufacturers should have a complete test process, such as: AOI testing, X-Ray testing, flying probe testing, functional testing, etc.

5.See industry certifications and standards

Quality flex PCB manufacturers should meet industry standards and have the appropriate certifications, such as ISO 9001, IPC-6013, RoHS certification and UL certification.

Looking for a high-quality flex PCB Assembly service? PCBasic focuses on precise and cost-effective flexible circuit assembly solutions to meet your project needs.

Contact us today for an instant quote and experience top-notch flex PCB assembly service!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.