Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > SMT vs. SMD vs. THT: Understanding the Differences

In the field of electronics manufacturing, SMT, SMD and THT are the three key terms that often appear in the PCB design and assembly process. They are often mentioned together, but SMT, SMD, and THT actually represent different concepts. SMT (Surface mount technology) and THT (Through hole technology) are two different ways to assemble a circuit board, while SMD (Surface mount component) is an electronic component designed specifically for the SMT process.

Understanding the differences between the three is crucial for engineers, designers, and those involved in electronics assembly. Next, this paper will explain the definition, characteristics and differences of SMT, SMD and THT in detail. Hopefully, it will help you make more informed decisions when choosing your production process.

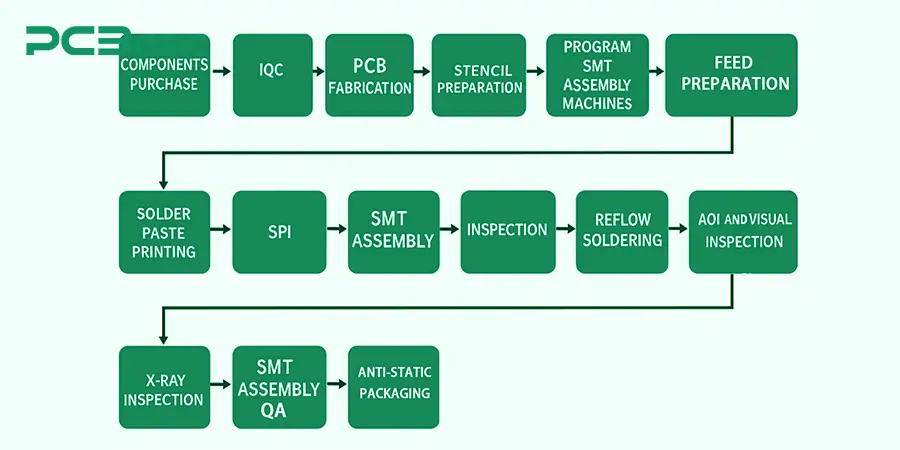

Surface Mount Technology (SMT) is a method of mounting electronic components directly on the surface of a printed circuit board (PCB), including solder paste printing, SPI inspection, original mount, reflow soldering, AOI inspection, X-ray (optional), rework and repair, and functional testing. Unlike through hole technology, SMT enables a more efficient, automated manufacturing process by placing components directly on the surface of the board, which is brushed with solder paste.

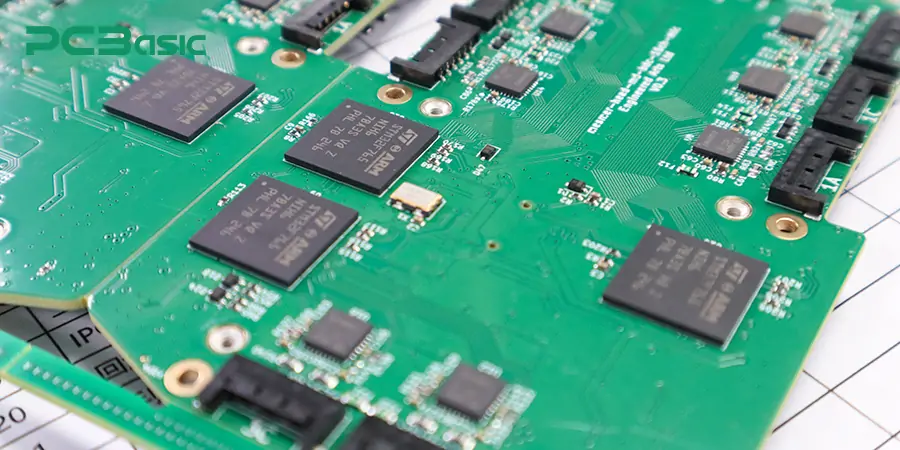

The SMT assembly process is a highly efficient and automated core technology in modern electronic manufacturing. Through surface mount technology, SMD components can be directly mounted on the surface of SMT PCBs without the need for drilling as in traditional through-hole mounting. SMT can achieve high-density and compact circuit design, which is one of its most prominent features. This characteristic makes SMT highly suitable for advanced products in industries such as automotive, medical, consumer electronics and communications.

A complete SMT production line usually includes steps such as solder paste printing, surface mount technology (SMT) placement, reflow soldering and AOI inspection. Compared with THT assembly, SMT production is more supportive of the miniaturization and mass production of electronic products. And through high-precision component placement and reliable soldering connections, the SMT assembly process can achieve long-term stable electrical performance.

Learn more about SMT in our comprehensive article here.

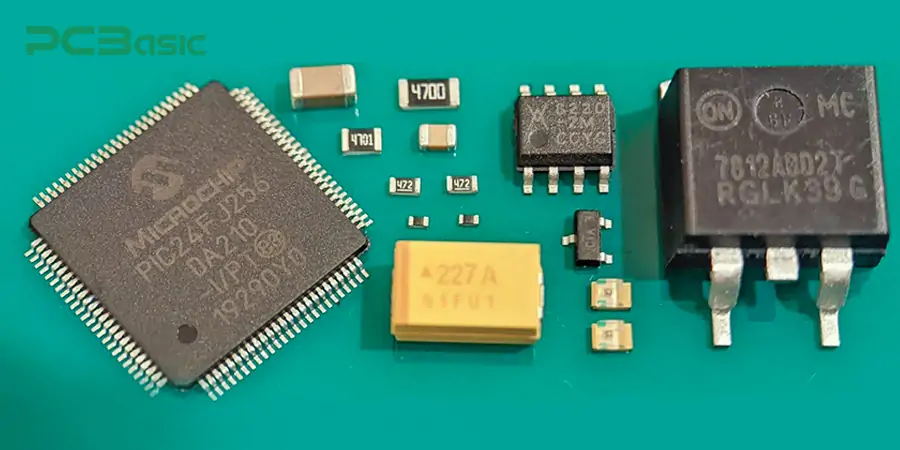

Surface Mount Components (SMD) refer to independent electronic components installed on the surface of a PCB through the SMT process. These components are specifically designed for direct mounting and are smaller, lighter and more efficient compared to traditional through-hole components. SMD components include resistors, capacitors, diodes, integrated circuits (ICs), etc. These SMD components are widely used in modern electronic devices.

Passive components: such as resistors, capacitors, and inductors, are used to control the flow of electrical signals and energy.

Discrete components: such as diodes, transistors, etc., process signals and perform various electronic functions.

Electromechanical components, such as connectors, switches, relays, etc., not only have electrical functions but also perform certain mechanical actions.

Compact size: SMD components are smaller in size than traditional through-hole components, making it easier to design more compact circuit boards.

Superior performance: SMD components are optimized for high-speed operation and are key components of applications such as high-frequency circuits and high-speed data transmission.

Learn more about SMD components in our comprehensive article here.

THT (Through-Hole Technology) is an assembly method in which component pins are inserted into pre-drilled holes on a PCB and soldered on the back. Unlike SMT, THT involves inserting component leads through drilled holes. THT was the main assembly technology before the popularization of SMT.

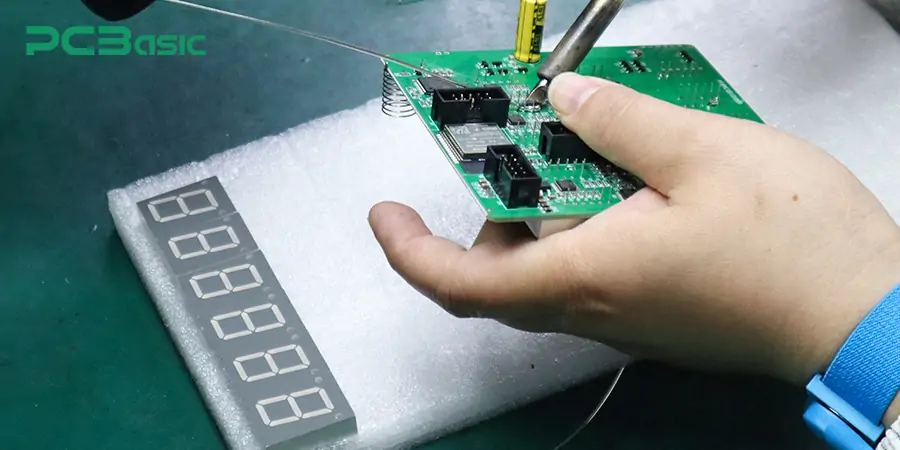

In THT assembly, what is used are through hole components with pins, such as resistors, capacitors, connectors, transistors, etc. These components are securely fastened by THT soldering methods such as wave soldering, selective wave soldering or manual soldering.

The pins of the Through hole components pass through the circuit board and are soldered on the back, which can provide stronger mechanical stability and is particularly suitable for application environments with high shock or vibration. Moreover, the Through hole technology can provide stronger electrical conductivity and heat dissipation performance, and is more suitable for high-current and high-voltage circuits.

For engineers, students or DIY enthusiasts, THT components are larger and easier to operate, making them ideal for prototyping and frequent replacement tests. However, THT requires drilling, which will occupy more PCB space. This limits the freedom of wiring and is not suitable for ultra-small electronic devices.

Learn more about THT vs SMT in our comprehensive article here.

|

Category |

SMT (Surface Mount Technology) |

SMD (Surface Mount Device) |

THT (Through-Hole Technology) |

|

Definition |

A PCB assembly method where components are mounted on the surface |

Components designed for SMT, with no or short leads |

A traditional assembly method where leads are inserted through PCB holes |

|

Type |

A manufacturing process |

A type of electronic component |

A manufacturing process |

|

Component Features |

Small, high-density, suitable for automated placement |

Compact packaging, optimized for high-speed automated assembly |

Long leads inserted through PCB holes, manually or wave soldered |

|

Application Scenarios |

Smartphones, medical devices, automotive electronics, telecom modules |

Used with SMT in a wide range of electronic products |

Industrial equipment, power modules, military/aerospace, educational kits |

|

Assembly Method |

Automatic placement + reflow soldering |

Placed by pick-and-place machines as part of the SMT process |

Manual or wave soldering, slower process |

|

Size & Density |

Supports compact, high-density PCB layouts |

Smaller size, short lead or leadless components |

Larger components, lower density layout |

|

Connection Strength |

Medium mechanical strength via pad soldering |

Strength depends on SMT process and footprint |

Strong mechanical bond, suitable for high-vibration environments |

|

Repairability |

Small components, relatively more difficult to rework |

Same as SMT; depends on size |

Easier to replace or rework by hand |

|

Common Examples |

SMT lines, pick-and-place machines, reflow ovens |

Chip resistors, capacitors, ICs (e.g., 0402, 0603 packages) |

Leaded capacitors, inductors, transformers, power resistors |

|

Key Advantages |

High efficiency, automation-ready, miniaturization-friendly |

Small footprint, enhances performance in modern electronics |

Stable and durable, suitable for high-power or high-voltage systems |

Understanding the differences between SMT, SMD and THT is crucial for circuit board design and assembly decisions. SMT and THT are two different assembly processes, while SMD refers to the electronic components installed on the circuit board through SMT.

In practical applications, design engineers will select the appropriate process based on product characteristics, usage environment and manufacturing cost. For some complex or highly reliable circuit boards, it is even necessary to combine SMT and THT processes to achieve a balance between performance and stability.

Whether pursuing high-speed automation or emphasizing electrical and structural strength, a deep understanding of the differences between SMT, SMD and THT is the foundation for achieving high-quality circuit board design and manufacturing.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.