Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: A Leading PCBA Manufacturer for Flexible Circuit Boards Assembly

Flexible electronics, also known as flexible circuit boards or Flexible Printed Circuit Boards (FPCs), have transformed the electronics industry. These new elements are built and used to bend, twist, and fold which makes them suitable for novel and cutting-edge devices where the mass of parts and space is at an utmost limitation. PCBasic focuses on high-standard manufacturing of flexible circuit board types, serving a wide range of industries, including consumer electronics to medical devices.

This article will provide a detailed overview of flexible circuit boards, including the material, advantages, and manufacturing process. Also in this article, we will showcase the professionalism of PCBasics, and how that professionalism will result in a better PCB build.

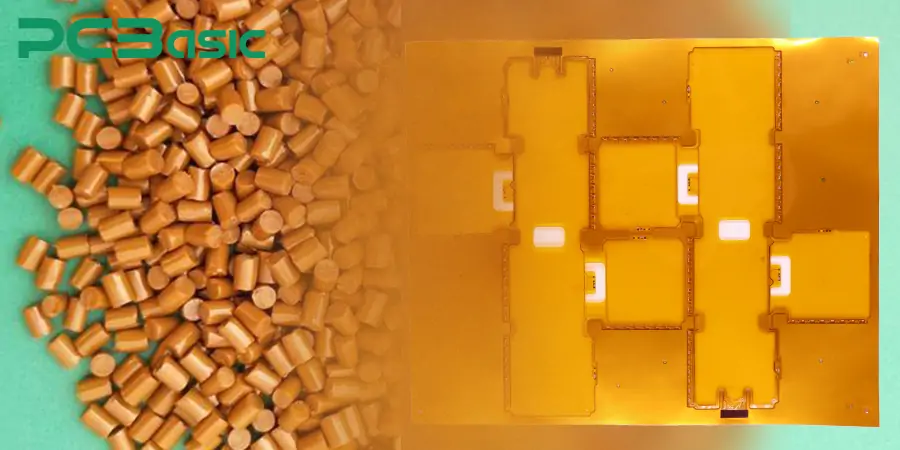

A flexible PCB is a kind of printed circuit board (PCB), which is made of flexible materials such as polyimide or polyester. In contrast to conventional and rigid PCBs, these PCBs can take on different shapes and can easily fit into crushed and small spaces. This edge makes it increasingly attractive for modern electronics applications like smartphones, wearables, aerospace technology, etc.

Commonly used materials in flexible circuit boards include a thin insulating polymer film, conductive copper traces, and protective coatings. Their unique design enables them to move dynamically, thus minimizing the need for connectors and wires, simplifying assembly, and improving reliability.

The majority of the performance of a flexible circuit board will be based on the materials used. So, here are the three biggest materials:

Polyimide (PI): With great heat stability and mechanical strength, polyimide is well known for being the most common Flexible PCB material. High temperatures resistant, suitable for demanding applications.

Polyester (PET): PET is an inexpensive, excellent material with good electrical properties. However, it exhibits less thermal resistance than polyimide, and hence not very useful in high-temperature applications.

Liquid Crystal Polymer (LCP): An excellent choice for high-frequency (5G) devices due to their low dielectric loss and high moisture resistance.

The right material is very critical for flexible circuit boards. Here’s a closer look at the three materials:

Polyester (PET) is a cheap material that is used in a lot of low-cost and low-performance applications.

Key Properties:

1. Thermal Resistance: Capable of working up to approximately 105 °C

5. Price: Cheapest of the three materials.

Advantages:

For consumer electronics with moderate heat requirements.

Disadvantages:

Does not work well under high-temperature applications.

Applications:

Cheap electronics: Calculators, TV remotes, etc.

Strong thermal and mechanical properties made polyimide the most widely used flexible circuit board material.

Key Properties:

5. Cost: Moderate.

Advantages:

Excellent mechanical flexibility.

Disadvantages:

Absorbs moisture.

Applications:

Scientific instruments and industrial machinery.

LCP is a high-performance material with excellent electrical and moisture resistance properties.

Key Properties:

5. Price: Most expensive of the three materials.

Advantages:

Lightweight and durable.

Disadvantages:

Limited availability.

Applications:

|

Material |

Thermal Stability |

Durability |

Flexibility |

Moisture Resistance |

Cost |

Typical Applications |

|

PET |

Up to 105°C |

Moderate |

Good |

Average |

Low |

Consumer electronics, such as remote controls and calculators |

|

PI (Polyimide) |

Up to 260°C |

Strong |

Excellent |

Good |

Medium |

Aerospace, medical devices, high-end electronic equipment |

|

LCP (Liquid Crystal Polymer) |

Up to 240°C |

Extremely strong |

Good |

Excellent |

High |

5G devices, RF modules, high-performance medical equipment |

While flexible boards have advantages, they have disadvantages as well. Let us go through them:

Advantages:

Lower cost: Fewer connectors and wires simplify the process.

Disadvantages:

Less breathing space for repairs: The repair operability of flexible circuits is much worse than conventional PCBs.

All the hurdles aside, the advantages of flexible circuit boards are far superior to the disadvantages.

Flexible circuit boards are manufactured with very high precision. Here is a step-by-step guide:

Material Selection: Based on the application requirements PI, PET, or LCP material can be selected.

CAD: To enhance performance, design the layout of the circuit with CAD.

Copper Lamination: A thin layer of copper material is provided to the base material with heat and pressure.

Etching: In this stage the excess copper is to be removed to have the needed circuit pattern.

Drilling and Plating: Make vias and coat each layer with conductive material for internal connections.

Pre-Applied coverlay: Place an additional layer for going to protect the circuit against environmental factors.

Quality Assurance and Control: Test boards to ensure that they meet relevant standards and specifications.

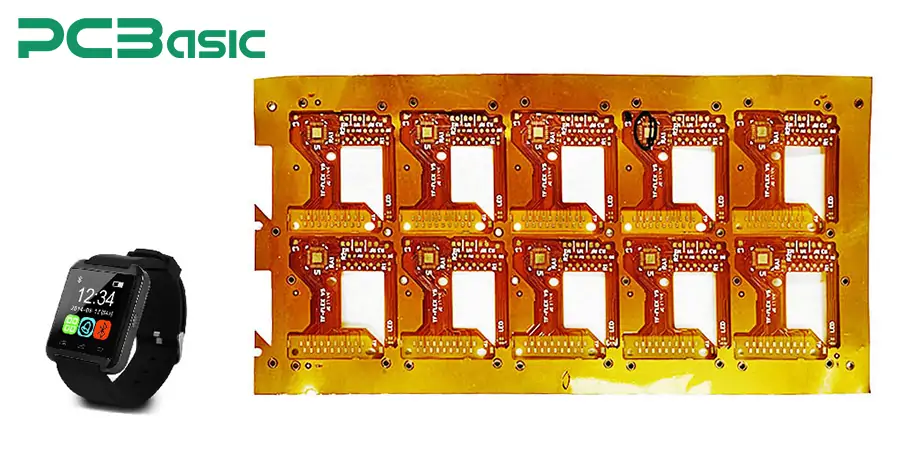

Consumer Electronics: Flexible circuit boards are found in smartphones, tablets, smartwatches, and many other electronics. Such electronics tend to restrict the manufacturer however by using flexible circuit boards, these electronics end up being more portable and lightweight.

Medical Devices: In the field of medicine, flexible circuit boards are found in devices that usually have compact spaces. For example, hearing aids and imaging equipment. Another thing is that their toughness and ability to endure repeated flexing make them ideal for implants and wearable health monitors.

Automotive Systems: Flexible PCBs are used by the automotive industry in advanced driver-assistance systems and sensors. They are even resistant to vibrations and harsh conditions, making them reliable when incorporated into cars.

Aerospace and Defense: Flexible circuit boards are extremely crucial for aerospace applications whose size and weight are one of the top priorities. Satellites, drones, and avionics systems offer very high reliability in extreme conditions.

PCBasic is a trusted name in the PCB industry that provides complete flexible circuit board Assembly services. The most comprehensive approach of any provider, our teams of experts work in partnership with our clients, utilizing state-of-the-art proprietary design and manufacturing methods that deliver solutions specific to the client's needs.

Professional Equipment: All work is done on commercial-grade tools to guarantee precision and effectiveness.

Quality testing: All product is quality tested.

Custom Solutions: Supports industries from automotive to medical devices.

Affordability: Cost-efficient product without compromising the quality.

Whether it's a few boards for prototyping or large-scale production, PCBasic will be the partner in flexible circuit board assembly.

Flex circuit boards are revolutionizing the electronics industry due to their capabilities. These advanced components are creating new opportunities in design and function—from smartphones to aerospace systems.

Here at PCBasic, we are proud to be at the cutting edge of flexible PCB technology. By adopting industry best practices and a focus on quality, we not only provide groundbreaking integrations, we help guarantee they are implemented to the highest standards. If you need a trusted company for your flexible circuit board supplier, reach out to PCBasic. Let us help you bring your ideas to life with cutting-edge PCB solutions.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.