Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBA Motherboard: What You Need to Know

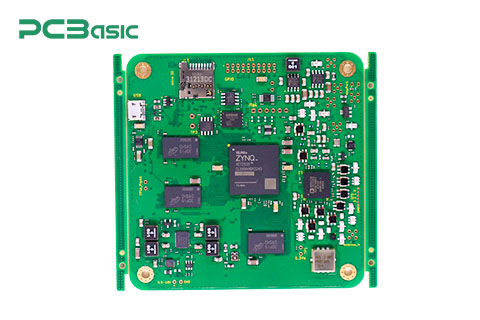

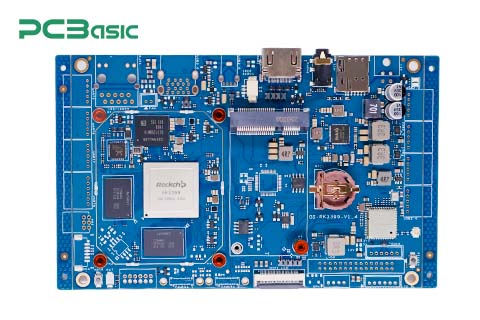

Do you know what a PCBA motherboard is? In popular terms, it refers to the assembled motherboard circuit board. PCBA motherboard is a vital component in modern electronic products, as the core of many electronic products, electronic motherboard PCBA assembly has become an important part of electronic manufacturing. A good PCBA motherboard can guarantee the efficient performance and reliable function of the equipment. From personal computers to industrial machinery, motherboard PCBA ensures that equipment has the circuitry needed to perform complex tasks. Here is an in-depth look at the concept of PCBA motherboards, the assembly process, the advantages of using high-quality assembly, common applications, and how to choose a reliable motherboard PCBA manufacturer. Hopefully, after reading this article, you have gained useful insights into the important role of PCBA motherboards in modern electronics manufacturing.

A PCBA motherboard is a printed circuit board component that is already fully equipped with electronic parts and ready to be integrated into a device. The term motherboard refers specifically to the central circuit board that connects all the electronic components in a device, such as the processor, memory module, power regulator, and communication interface. When the motherboard is called a PCBA motherboard, it means that it has completed the welding of the components and is fully ready to be put into use.

In contrast, a standard electronic board may simply refer to a bare PCB with no electronic components. A PCB is an unassembled version of a motherboard, and it is a key part of the PCBA motherboard process. Once a PCB is filled with elements and properly tested, it can be used as a major component in a variety of electronic devices. The process of converting a motherboard PCB to a fully assembled PCBA motherboard involves multiple assembly and quality control phases, including component placement, welding, and testing to ensure that the PCBA motherboard meets specifications and works properly.

The assembly process of PCBA motherboard is similar to the ordinary PCBA process, but the process of PCBA motherboard is more complex and requires precise control.

After the PCB is produced in accordance with the requirements and the required components are purchased, the next step is the component placement stage. It’s the first step of critical PCB assembly. A PCBA motherboard manufacturer will typically use an automated device to place individual electronic components onto a board, such as a chip mounter, which is capable of placing hundreds of components onto a PCBA motherboard with high precision. Each component is selected according to design specifications, and these components include resistors, capacitors, integrated circuits (ICs), and connectors.

After the components are placed, the next step is soldering. This is a key step in the motherboard PCBA assembly process, and there are two main soldering methods:

SMT (Surface Mount technology) is to solder components to the surface of the PCB and is usually used for smaller and high-density components. This method is efficient and can assemble a large number of PCBA motherboards in a short time. DIP, in which components are inserted through the holes in the PCB and soldered on the other side, is usually used for larger components that require a stronger connection.

After soldering, the motherboard PCBA is checked to ensure that all connections are correct and that there are no defects or cold solder spots.

To ensure that the PCBA motherboard is fully functional, rigorous testing is carried out at all stages of the assembly process. These tests may include:

·Flying probe test: A non-invasive method for checking the continuity of electrical connections and verifying the presence of short or open circuits.

·X-ray inspection: A technique used to detect solder defects, such as solder spots hidden under components, to ensure the quality of the connection.

·Functional testing: Once the PCBA motherboard is assembled, the functional test is performed to verify that all components work seamlessly together to ensure that the final product functions as intended.

These quality control measures are essential to reduce defects and ensure the reliability of PCBA motherboards.

Be sure to choose a high-quality PCB assembly to produce electronic motherboards, because the higher the quality of the PCBA motherboard, the better in terms of performance, durability and reliability. Here are some of the advantages of high-quality PCBA motherboards:

A motherboard PCBA can be called high quality, then all its components must first be properly placed and welded. Such boards have fewer electrical faults and ensure smooth operation of the final product.

The higher the quality of the board, the higher the precision of the component placement and soldering stage, the less the possibility of defects.

The quality of the material and the assembly process can directly affect the service life of the PCBA motherboard. Good soldering and thorough testing ensure that the motherboard can withstand ambient pressure, temperature fluctuations and electrical loads, increasing the durability of the final product.

|

Industry |

Application Areas |

Key Functions |

|

Computing & Consumer Electronics |

Computers, laptops, consumer electronics |

Efficient operation |

|

Telecommunications |

Routers, switches, base stations |

Data processing and communication functions |

|

Automotive Industry |

Engine Control Units (ECU), infotainment systems |

Reliable operation of critical functions |

|

Medical Devices |

Diagnostic instruments, monitoring systems, imaging devices |

Precision and safety in critical applications |

To select a reliable PCBA motherboard manufacturer, first of all, choose a manufacturer with strict quality control processes and related certifications such as ISO 9001, ISO 14001 and ISO 45001. These certifications at least demonstrate that the manufacturer is able to follow best practices and comply with industry standards.

A reliable PCBA motherboard manufacturer must have many years of PCB assembly experience in electronic motherboards and be able to provide solutions during the assembly process, such as, PCBasic.

A reliable manufacturer should have advanced assembly and test equipment such as flying probe testing, AOI and X-ray inspection systems.

Strong communication and customer support are essential when working with motherboard PCBA manufacturers. A good manufacturer will work closely with you to ensure that the PCBA motherboard meets your specifications and requirements.

The assembly process for electronic PCBA motherboards is critical to ensuring the performance, reliability and durability of the final product. It is hoped that by understanding the PCBA motherboard assembly process, advantages, applications and choosing the right manufacturer discussed in this article, you can better choose PCBA motherboard assembly manufacturing services.

If you are looking for a reliable PCBA motherboard manufacturing partner, it is recommended to choose an experienced supplier who can provide high quality assembly to meet your specific needs. Investing in quality PCB assemblies for electronic motherboards will ultimately improve product performance and give you a competitive advantage in the marketplace. Please allow me to recommend PCBasic to you, if you are willing to learn about it, it will not disappoint you.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.