Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: A China PCB Assembler for Low-cost PCB Assembly

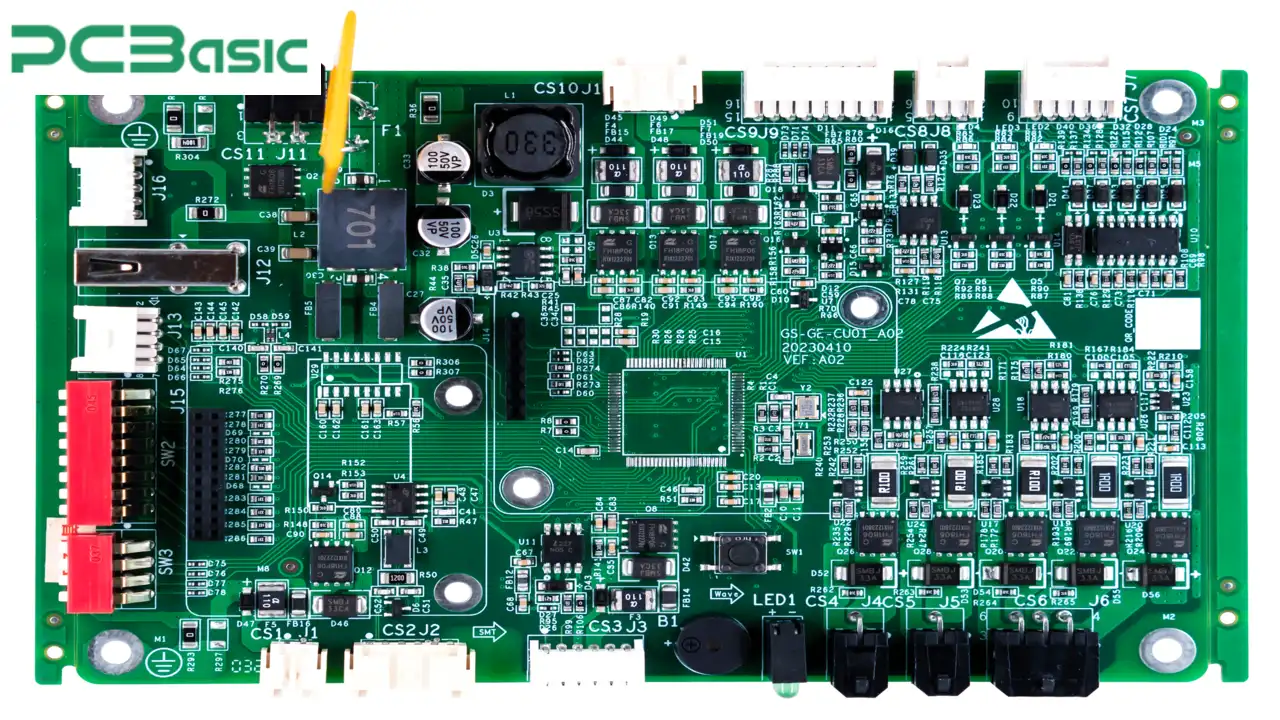

PCB manufacturing and PCB assembly, without them, the whole electronic production will just be ideas, figuring out how to become real working devices. PCBasic is a Shenzhen, China-based PCB assembly manufacturer serving the needs of any business that wants high-quality, low-cost PCB assembly.

Being the industry leader, PCBasic offers an extensive PCBA services portfolio ranging from one-stop solutions, custom PCB design to prototype PCB assembly. The company specializes in providing low-cost and high-reliability solutions to the customers.

Whether it is for small-batch prototype manufacturing or large-scale production, PCBasic can provide flexible and efficient services according to customer demands and become the preferred PCB assembler for low cost and high reliability.

Printed circuit board assembly (PCBA) is a precise process of mounting electronic components onto a printed circuit board (PCB); it is a key step in transforming a bare board into a functional electronic product. Here let’s learn several common items about circuit board assembly.

Custom PCBA

Different electronic products have different designs and application needs, so PCBA needs to be customized according to specific product requirements. With customized solutions, it can ensure that the board perfectly matches the design requirements and functional requirements. For example, for different working environments or specific requirements, customized PCBA can use special materials, enhanced high-temperature resistance, or finer circuit layouts.

Prototype PCB Assembly

Prototype PCB assembly refers to the fact that in the early stage of product development, the PCB assembly manufacturers produce and assemble one or more experimental models of the circuit boards to test using the circuit diagram and PCB layout from the design team. The process is an essential remodeling of a theoretical design into physical hardware with a clear target to validate that the design works, the circuit performs as it should, and the possible design issues are identified.

In prototype PCB assembly, engineers usually choose a small number of boards for assembly rather than producing a large number of boards as in mass production. The components and soldering methods on these prototype boards are relatively simple, and the purpose is to quickly verify the basic function and performance of the design rather than for high-precision production. With this small-batch assembly, the design team is able to detect problems early and make adjustments to reduce the risk of later mass production.

PCB Assembly Cost

The PCB assembly cost is affected by various factors. First of all, the cost of the materials used is one of the important factors affecting the price, especially high-end components and special materials. In addition, the design complexity also directly affects the assembly cost. The more complex the circuit design, the more processes and accuracy requirements are usually required. Finally, testing requirements, such as functional testing, withstand voltage testing, and flying probe testing can also add to the cost, as these tests require additional equipment and time to ensure the reliability of the board.

Founded in 2011 in Shenzhen, China, PCBasic has accumulated over 10 years of experience and has become a leading enterprise in PCB manufacturing and assembly. The company is dedicated to offering a comprehensive suite of solutions to its customers, ranging from quick-turn PCB Assembly services to custom design and one-stop services.

• Quality control: PCBasic attaches great importance to product quality and adopts a series of advanced testing technologies to ensure that the quality of each PCB is up to the highest standards. The company uses AOI (Automatic Optical Inspection), X-ray, SPI, ICT, and flying probe testing to reduce potential defects in production and ensure superior quality of the final product.

• Advanced SMT production lines: PCBasic is equipped with fully automated SMT production lines, using modern equipment and technology to improve the efficiency and accuracy of the PCB assembly. This enables greater speed and precision in the production process while greatly improving product consistency and ensuring high-quality production output.

• Quick Turn PCB Assembly Services: In the face of growing market demands, PCBasic has flexibility in production planning and can effectively respond to the needs of urgent projects. The company is able to complete the production and delivery of products in a very short period of time, as short as 24 to 36 hours to complete the delivery, ensuring that customers can quickly get the products they need at a critical moment and avoid delays due to waiting.

Whether you need small-batch production or high-volume manufacturing, PCBasic’s expertise as a leading PCB assembly company ensures consistent quality.

Designed to serve a wide range of industries and client needs, PCBasic offers a full complement of services. From automotive, medical devices, and IoT to aerospace applications, PCBasic also offers customized solutions because each project has its own needs. PCBasic offers some key services as follows:

1. Custom PCB Design and Assembly

PCBasic offers custom PCB design and assembly services tailored to various industries, including:

• Automotive: Providing highly reliable and durable PCB design and assembly for automotive electronics.

• Medical Devices: Offering precise PCB designs to ensure safe, stable, and efficient electrical performance for medical devices.

• Internet of Things (IoT): Meeting the requirements for miniaturization, low power consumption, and efficient connectivity in IoT devices.

• Aerospace: Providing highly reliable and precise PCB solutions for aerospace applications.

Additionally, PCBasic supports complex PCB designs, including multi-layer boards (up to 40 layers), catering to high-density, high-performance circuit needs.

2. Prototype PCB Assembly

PCBasic provides prototype PCB assembly services with no minimum order quantity (MOQ) requirements, which is ideal for early-stage development. Advantages include:

• Low Cost: Offering cost-effective prototype production for clients needing to validate and test their designs.

• Fast Turnaround: With efficient production processes, PCBasic helps clients accelerate product development, shortening time-to-market.

3. One-Stop PCB Assembly

PCBasic offers one-stop services that cover the entire process from component procurement and PCB manufacturing to final assembly. This service is particularly beneficial for:

• Small-Batch Production: Providing affordable solutions for clients’ initial small-volume production needs.

• Mass Production: Ensuring consistent quality for large orders while optimizing production costs.

Whether it’s small or large-scale production, PCBasic offers flexible, efficient, and cost-effective solutions to ensure projects are delivered on time and meet quality standards.

4. Competitive Pricing

PCBasic delivers competitive prices for PCB boards by minimizing total costs through lean manufacturing processes and economies of scale. Furthermore, PCBasic is also transparent about pricing, so the client knows how much every aspect of the project costs, without hidden costs or a last-minute dust charge.

5. Fast Turnaround PCB Assembly Services

To meet urgent project needs, PCBasic offers fast turnaround services, helping clients complete PCB assembly in a short timeframe:

• Quick Delivery: PCBasic can deliver assemblies without compromising on quality, with some orders completed in as little as 24 to 36 hours.

• Meeting Urgent Needs: For clients with urgent delivery requirements, PCBasic offers flexible production scheduling to ensure products are delivered on time, preventing project delays.

If you want a reliable and low-cost service when it comes to PCB manufacturing and assembly, PCBasic can be your best solution. This outstanding PCB assembly manufacturer focuses on custom designs, engineer-set-up, advanced SMT production lines, and quality assurance, guaranteeing every project observes top-quality conditions. Providing everything from a one-off prototype to mass manufacture, PCBasic offers a complete service that enables it to outperform many competitors in a crowded electronics manufacturer landscape.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.