Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Get PCB Prototyping Services from PCBasic

Printed circuit board (PCB) prototyping is a crucial step in the development of electronic devices. With PCB prototyping, engineers can design, manufacture, and test initial versions of PCBs to verify their functionality and prepare them for mass production.

As a leading China PCB and PCB assembly manufacturer, PCBasic offers comprehensive PCB prototyping services to ensure speed, accuracy and reliability. With more than 10 years of PCB manufacturing and prototype PCB assembly experience, PCBasic is your trusted partner for custom PCB solutions.

PCB prototypes refer to a small number of circuit board samples made according to the preliminary design scheme, mainly used to verify the function and performance of the circuit design. At this stage, the designer tests various parts of the board to ensure that each component is working properly and to find possible design defects. This is a very important step, as through prototype testing, problems can be detected early and a wider range of errors can be avoided in later mass production.

Specifically, prototype testing can help designers optimize circuit layout and check signal integrity, power distribution, and thermal management to ensure that the board can operate stably in real-world applications. After confirming that there are no problems with the design and ensuring that the PCB board assembly meets the standard, the prototype circuit board will lay the foundation for mass production, making the production process smoother.

Working with a professional PCB manufacturer like PCBasic ensures that every prototype board is precisely tested and validated. Reliable manufacturers can not only help ensure the accuracy of the design, but also speed up the development and time to market of the product, because they have extensive production experience and advanced equipment to respond quickly and provide high-quality prototype boards. This provides customers with great assurance in subsequent mass production, ensuring that the final product meets the expected standards.

PCB prototyping is a crucial step in the development of electronic products, especially in different fields of application, to ensure the accuracy of the design, the reliability of the performance and the stability of the product.

Automotive Electronics: In the automotive industry, advanced driver assistance systems (ADAS) and in-vehicle infotainment systems place high demands on PCB quality and performance. With PCB prototyping, the design team can verify the function of the circuit board and ensure the stability and safety of the system, especially in harsh driving environments.

Medical Devices: The medical industry relies on precise and high-performance devices such as diagnostic tools and wearable health monitoring devices. PCB prototyping helps to ensure that the board can meet strict medical standards and can work stably in the human environment to ensure patient safety.

Industrial Control: In industrial automation systems and sensor applications, PCB stability and reliability are critical. Through PCB prototyping, manufacturers can ensure that the circuit board can operate in high load and complex environments to ensure the accuracy and efficiency of the system.

Aerospace: Navigation systems and communication modules in the aerospace sector require extremely high reliability and precision. Through PCB prototyping, engineers can simulate working conditions in various extreme environments to ensure the stability and safety of the circuit board in special environments such as air and space.

PCBasic has extensive experience in these areas and its prototype PCB assembly services meet the highest quality and performance standards.

PCBasic provides comprehensive services to meet the needs of different types of PCB prototyping, ensuring that every project can be completed efficiently and accurately.

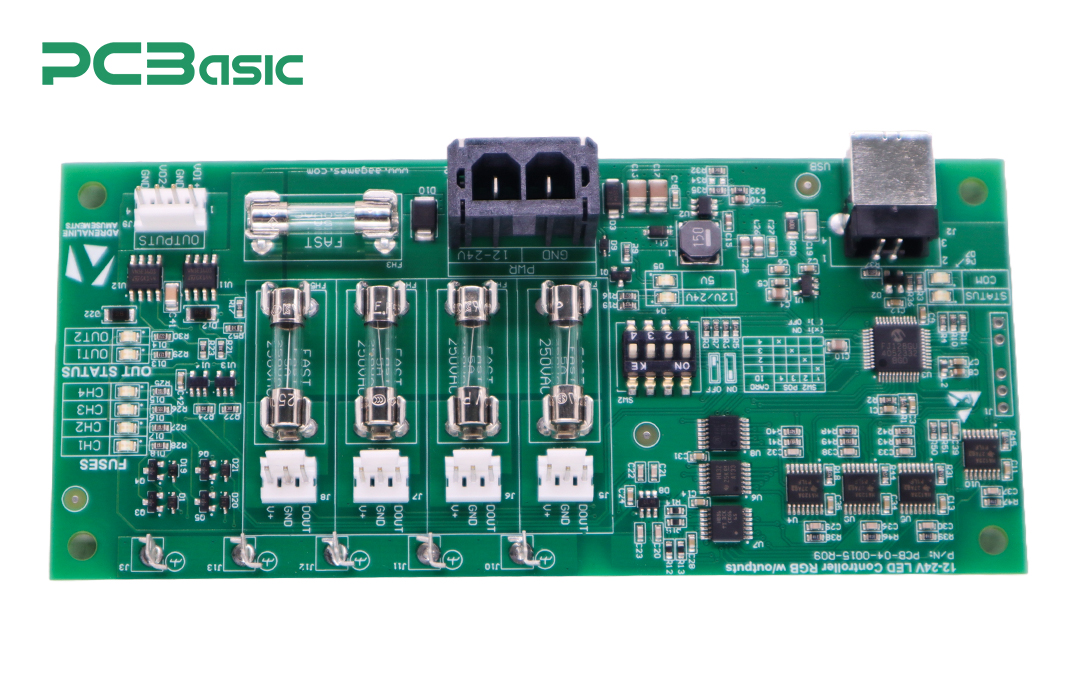

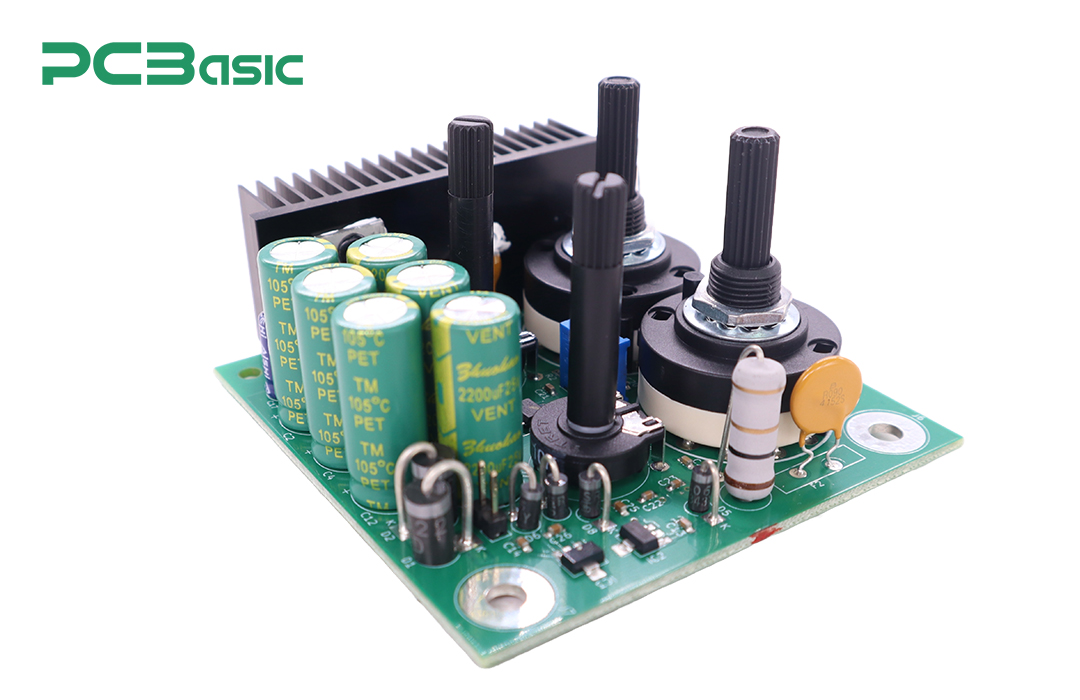

PCBasic focuses on providing custom PCB design and manufacturing services. Whether it is a simple single-layer board or complex multi-layer design, they can be precisely designed and produced efficiently according to your specific needs.

In the process of rapid development and testing, speed is also one of the core competencies of PCBasic. It utilizes advanced manufacturing processes and intelligent management systems, such as CRM, MES, ERP, to optimize production processes and ensure fast delivery. For small orders, PCBasic can typically complete the PCB prototypes within 12 to 24 hours, greatly reducing the development cycle and helping customers test and validate designs more quickly.

PCBasic uses the latest technology and precision equipment in PCB prototype manufacturing to ensure the accuracy and high quality of each prototype. Their factories in Shenzhen and Huizhou are capable of handling both rapid small-batch prototyping and large-scale production demands, fully meeting the diverse needs of customers.

In addition, PCBasic provides complete one-stop PCB design and assembly services, from the initial circuit design, PCB layout to the automatic installation and assembly of components, the entire process is controlled by a team of experienced engineers to ensure seamless design and production. Each component can be accurately integrated to achieve optimal electrical performance and guarantee the reliability and stability of the final product.

When you choose PCBasic as your PCB prototype and assembly partner, you get a lot of advantages and guarantees.

1. No minimum order quantity

With PCBasic, you don't need to worry about the minimum limit of the number of orders. Whether you need a small number of sample tests or a smaller production batch, PCBasic has the flexibility to meet your needs. You can order any number of boards according to the needs of your actual project.

2. Free Assembly Fee for First Prototype

For start-ups, small businesses, or individual developers, PCBasic's first prototype free assembly fee service is a special benefit. This means you can test your design and verify functionality without risk or additional assembly costs, making it ideal for companies with limited budgets.

3. High Quality Standards

PCBasic is committed to providing high-quality products and has received several international certifications, including ISO9001, IATF16949, ISO13485 and UL, to ensure that products meet the highest quality standards in the industry during manufacturing. These certifications represent PCBasic's expertise in quality management, manufacturing processes, and safety, and you can choose from its services with confidence.

4. Advanced Technology

PCBasic is equipped with advanced automated optical inspection (AOI), reflow soldering and X-ray analysis, flying probe testing and other technologies that accurately inspect the quality of each circuit board, ensuring that both soldering accuracy and overall design meet the highest standards.

5. Dedicated Support

PCBasic has a dedicated team of more than 30 experienced engineers who are ready to support your project. Whether in the design phase or during the production process, you have access to 24/7 technical support to ensure that the project is progressing smoothly and any unexpected problems are resolved.

PCBasic is recognized as one of the best PCB prototyping services providers for reliability and efficiency. Empowering the PCB assembly services, it serves a variety of industries with its quality and modern technology. From one prototype to large-scale production, every project gets what it deserves with PCBasic!

Choose PCBasic for your next project to experience the best in PCB prototype fabrication service, custom designs, and fast delivery. Transform your ideas into reality with one of the most trusted names in the industry!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support