Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Connector Types| A Comprehensive Guide

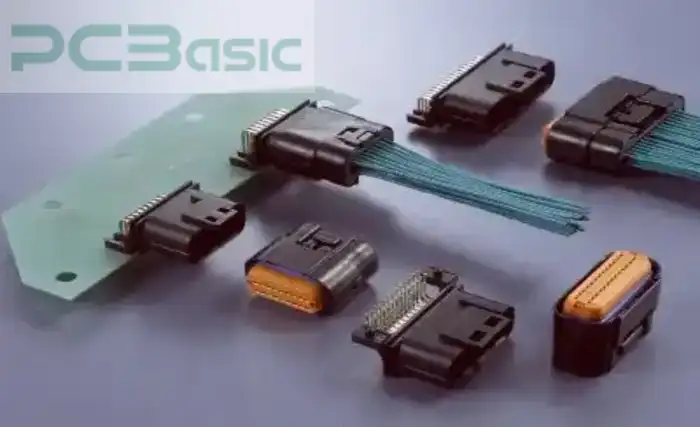

PCB connection is one of the most crucial aspects of electrical and electronics engineering. They are used to connect smaller sections of a particular circuit board. PCB connectors ensure that power and signal or data transfers are well articulated.

Engineers and designers must familiarize themselves with various PCB connector types. These connectors are useful for the general functionality and performance of practically all electronics.

Now let us focus on the features of the connectors used in PCBs, as well as their types.

PCB connector is a hardware element that connects different parts of an electronic circuit. It is used to join different points on a printed circuit board to have the ability to transfer either signal or power between the joined points.

PCB connectors are classified in different sizes and shapes depending on the required demand. If you connect wires to a board, connecting two boards or connecting cables, the right PCB connector makes the job run smoothly. First of all, they are needed for integrating and connecting the circuits of numerous types of electronics.

It is very important to understand that there are many PCB power connector types. Engineers must know all these and also the applications that are associated with them. This assists them to determine the most appropriate one to use for the particular project that they have.

By going through these categories, engineers can easily identify the ideal connector for their application.

There are four main PCB connector types.

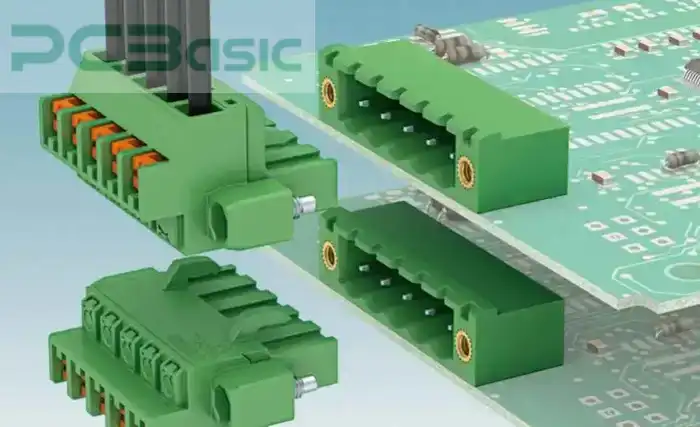

Board-to-board connectors make direct PCB connections between two circuit boards PCB power connector types. It has sub-types which are the mezzanine, coplanar, and the stacking type of vertical conveyor systems. Usually, they’re found in places where space is a problem. These connectors are used where numbers of PCBs are to be interconnected without any warrant of complicated wiring. Due to their small size, they are ideal, especially in the telecom and electronics industries.

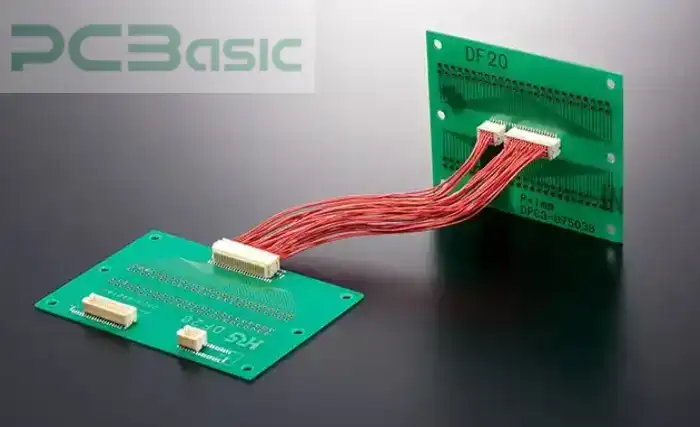

Wire-to-board connectors mate individual wires with PCB while wire-to-wire connectors connect one wire with another wire. They are widely used in outlets such as those that require direct electrical connections. These connectors then provide relevant firm connections with the PCB wire connector types and the board respectively. It deals with microcurrent loads of various kinds thereby making it suitable for automotive and industrial applications.

This is a type of connector which connects one cable to another cable. They are normally fitted in areas where easy wiring maneuverability is necessary. Some have locks for the security of the connection to ensure that nobody else previews the webcams. Many come with locks to keep the connection secure. They are used in home appliances and networking devices, among others. These connectors ensure that signal integrity is maintained as is the case for longer cable distances.

Board-to-cable connectors connect a cable to a PCB. It has features of wire-to-board connectors and cable-to-cable systems, which enables it to offer the best of both worlds. Often used in circuits that require devices capable of constructing and breaking PCB connections with ease, electronics employing flexible circuits predominantly use these connectors. Board-to-cable connectors are long-lasting and offer a stable signal transfer. It is very essential in areas such as computing and telecommunication.

PCB connectors can be specified by the application.

Backplane connectors connect more than two PCBs, but usually, the number is greater than two. They enable a high data transfer rate with faster performance and also enhance power delivery. It is used in servers, telecom equipment as well as in data centers. These connectors are particularly important with systems that require repeated updates or even physical alteration in hardware.

Jacks are found in most computers or devices that deal with sound and visual signals in the form of audio and video connectors. It is usually found in home theatre systems, gaming consoles, and other professional audiovisual equipment. These connectors provide an optimum sound and vision quality and there is no interference at all.

Automotive connectors are tough. It can withstand high or low temperatures as well as constant and continuous vibrations. For that, they are responsible for establishing dependable lines for everything from the engine to the controls to the infotainment. Safety and performance in most of today’s cars depend more on these connectors.

Card edge connectors are those that are fixed on the edge of a circuit card. They provide high-density connections. You will come across them in computers and other devices that may need easy swapping or enhancement.

Circular connectors are highly reliable and they also can be used in various applications to make sure they are strong. Most of them are round-shaped which helps in preventing them from wearing out due to environmental factors. These are used in aerospace, military, and heavy industrial applications machinery.

D-sub connectors can easily be identified by their D-shaped metal shield. They are commonly present in computers and many other types of industrial equipment. They act as proper connectors for the supply of power and datability.

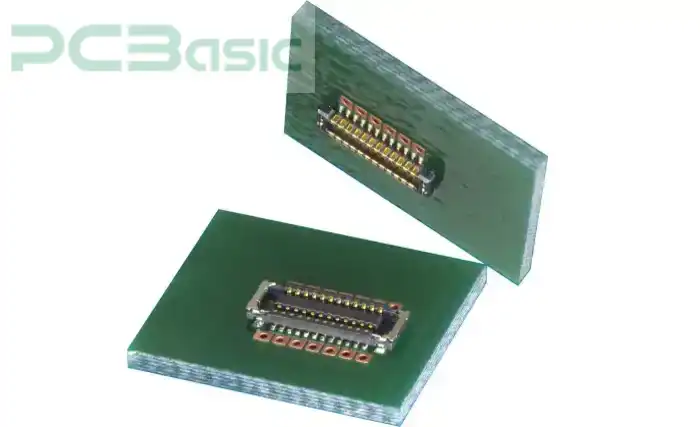

As for FFC and FPC connectors, it is possible to note that they are suitable for usage in compact devices. They offer easy means of interconnecting the circuit boards. You will come across them in mobile phones, laptops, and other devices that require compact devices since space is limited.

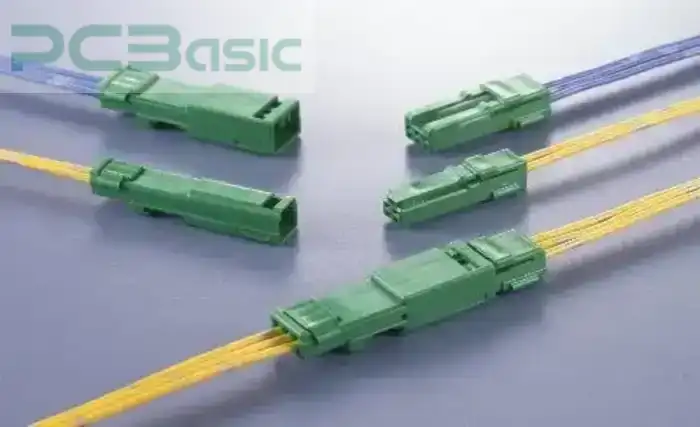

Fiber optic connectors, on the other hand, convey data in light. They are fast and have security as a core aspect of the communication between the devices. These connectors are used in Internet structures and many types of medical imaging apparatus.

Ethernet connectors are used in networking as a common tool. These people inform computers, routers, and switches for high Internet speed. You will meet them in homes and offices to enable the availability of stable networks.

Solar connectors connect solar panels to inverters among other related devices. They are designed in such a manner that will enable them to withstand outside environments. These connectors have really important functions in solar energy systems, thus, making renewable energy more affordable.

PCB Power connectors transfer power from one component to the other or right to the concerned device. They are in almost every electronic product that you use. These PCB Power connectors ensure that the power is well-regulated and that there is a power supply without eventualities.

High-frequency signal transmission is done by RF coaxial connectors. Some examples can be found in communication systems as in antennas and satellites. These connectors are very important in reducing signal loss.

USB connectors are everywhere. They deal with data connectivity and energy for such products as smartphones, tablets, and computers. USB remains a relevant standard, with new standards that provide for higher speeds and better power delivery.

Memory sockets join memory to the motherboard and are also referred to as memory connectors. It is found most commonly in computers and servers as well as in any application where you need to have some extra memory that is easily expansible.

Thanks to sockets, it and its components are easy to install and replace if needed. They do not use soldering and as such they can be used in a prototype design and the production of large quantities.

Terminal PCB connector types are many and their main function is to connect wires in electrical circuits. They do not require a lot of work to be put up and they can also hardly be serviced. Terminal PCB connector types are used in industrial control systems and power distribution systems among others.

It will be essential to look at a few various types of modified PCB connectors, that have been designed for specific requirements and uses.

High-frequency PCB connectors enable signal transfer of high frequencies without distortion or loss.

● High-Frequency PCB Connectors are used in:

● RF amplifiers

● Radiofrequency (RF) systems

● Microwave devices

● High-speed data transmission

● Mixers

● Oscillators

● High-speed data interfaces

The reason for using rugged and waterproof connectors is to face severe weather conditions for the PCB assemblies. Some of the above environmental factors include high and low temperatures, vibration movement, dust, and dampness.

These connectors are necessary for items like:

● Outdoor electronic devices

● Industrial automation systems

● Military equipment

The goal of miniaturized PCB connector design is to reduce the size. This tiny dimension enables a smaller board and higher component density.

These connectors are essential in:

● Wearable devices

● Smartphones

● Portable electronics

Challenge: Minimizing size without affecting electrical performance or efficiency.

Solutions:

● Advanced manufacturing techniques

● High-density contact configurations

● Use of smaller wire gauges

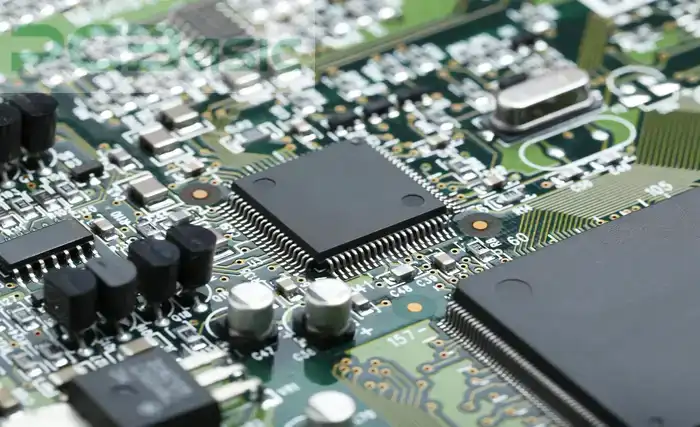

With just a small footprint, high-density PCB connectors can hold a lot of PCB connections.

Advantages and Applications:

● Essential in limited space and high-density interconnections

● High-performance computing

● Data centers

● Telecommunications equipment

Improvements in manufacturing processes and materials science contribute to the development of PCB connector designs.

Performance, stability, and cost have all improved as a result of these developments.

Connectors with improved qualities are being made from materials such as conductive polymers, high-temperature plastics, and specialty alloys.

High-quality connections are produced effectively through the use of advanced manufacturing techniques. These methods consist of automated assembly, precise machining, and laser cutting.

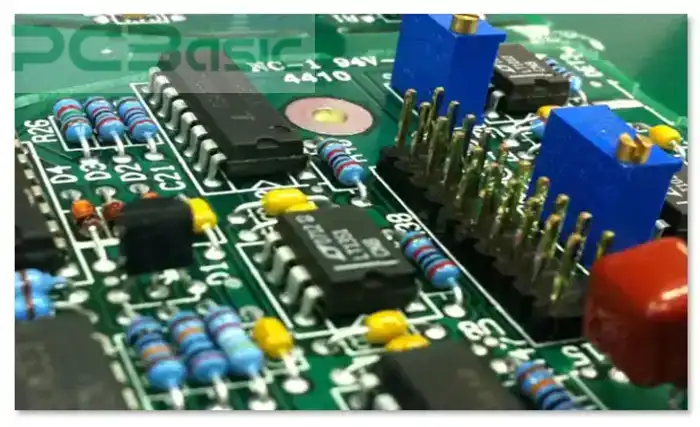

SMT mounting is a kind of PCB surface placement of connectors in which connectors are directly mounted.

Several benefits of the above method include:

● It has a slightly smaller size and is much denser in terms of its component concentration.

● It is faster in production and assembly compared to THT connectors.

● As can be seen, fast manufacturing means a decrease in the time required for production.

● On the other hand, it is generally attributable to lower manufacturing costs, particularly through automated assembly processes.

● The most common technique of mounting is where the connector leads are passed through holes provided in the printed circuit board connector types.

● One of the crucial advantages of THT connectors is that they have a better mechanical connection than SMT connectors.

● Most of the THT connectors are generally larger and require more time for their manufacturing and connection.

● SMT, as well as THT components, are mounted on a single PCB through hybrid mounting methods.

● Circuit board hybrid mounting is applied in complex electronic circuits with different sizes and kinds of components.

It is important to take the following factors into thought while choosing PCB connectors:

● The specificities of the electronic tool being used; include performance, operations, and environmental aspects.

● How well do the connectors interface with the other components in the circuit?

● The required signal integrity, voltage, and current.

● What type of connector it is, the size and the shape of the connector, and how it needs to be mounted.

● Other environmental considerations, for example, are the vibration, humidity, and operation temperature of the system.

● The cost of the connector and the availability of its suppliers.

PCB connectors enable the interconnection of various parts in electrical circuits. To be useful in the construction of efficient and dependable electric devices, it is important to know the different types of PCB connectors and their applications.

Assembly Enquiry

Instant Quote