Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Flying Probe Tester: Maintenance and Repair

The quality and functionality of printed circuit boards and PCB assemblies are critical to electronic products, which are a primary concern in the production process. Therefore, it is extremely important to detect them during the production process. Flying probe testing is a very flexible and cost-effective test method used by manufacturers to detect defects in a bare board or PCB assembly.

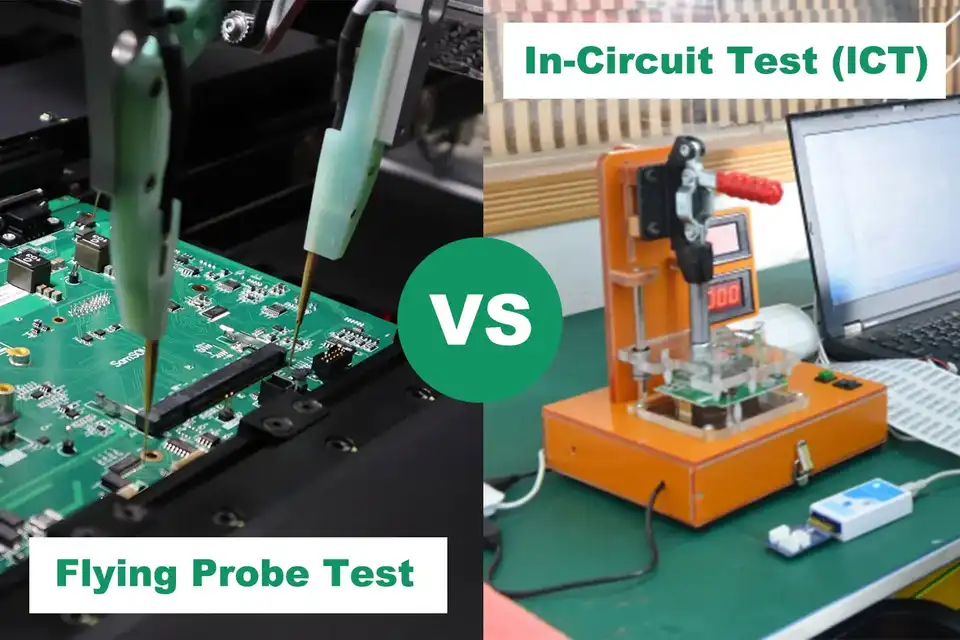

Compared to traditional ICT testing, the flying probe tester offers greater flexibility, especially in low to medium volume production. However, like any complex device, a flying probe tester requires regular maintenance and repairs to ensure it works efficiently.

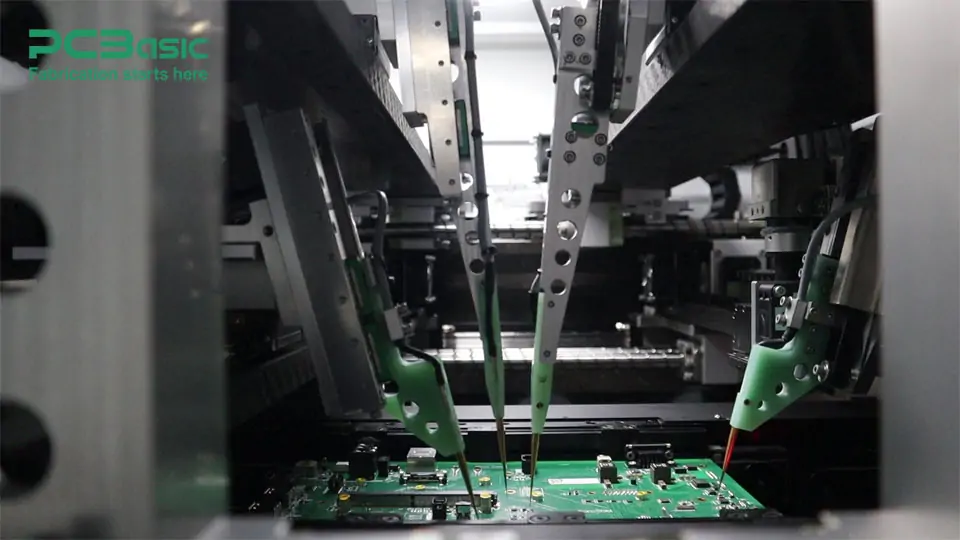

In PCB manufacturing and assembly, flying probe testing is a non-contact testing method for electronic boards that can test open circuit, short circuit, component orientation and other problems in electronic located in the circuit board, especially, for SMD components. In this method, a flying probe machine tests the connection by contacting test points on the test area of a circuit board with a series of test probes.

A software program in the flying probe tester controls the motion of the probes and the test points to be tested. This method is generally used in prototype or low-volume situation because it may be not cost-effective to build dedicated test fixtures for ICT testing.

Both flying probe testing and ICT testing are used for quality control in PCB assembly, but they differ in their methods and features. ICT testing uses custom ICT fixtures to contact circuit boards with test points. Each fixture is tailored to a specific design and board type, making it ideal for testing large numbers of identical boards in mass production.

In contrast, flying probe testers offer a more flexible and cost-effective solution for low to medium volume production. The flying probe tester can be quickly adjusted to suit different board designs and sizes and provides extremely accurate test coverage, even on boards with complex designs or irregular test points. Flying probe testing is especially important for side board that require frequent design changes.

Let’s compare flying probe vs ICT in a chart below.

|

Feature |

Flying Probe Testing |

In-Circuit Testing (ICT) |

|

Cost |

More cost-effective for low-volume runs |

Expensive due to test fixture setup |

|

Speed |

Slower, more time-consuming |

Faster, ideal for high-volume production |

|

Flexibility |

Highly flexible, easily reprogrammed |

Limited flexibility, fixed test fixture |

|

Testing Coverage |

Limited test points, less thorough |

Comprehensive testing of all components and connections |

|

Suitability for Prototypes |

Ideal for prototypes and small batches |

Not suitable for prototypes due to high setup costs |

|

Risk of Damage |

No risk of damage to components |

Risk of damage to SMD components from bed nails |

|

Best Use Case |

Low-volume, custom boards, quick turnarounds |

High-volume PCB assembly, mass production runs |

In order to ensure the efficient operation of flying probe testers, regular maintenance is essential.

Regular Inspection: One of the most important maintenances of the flying probe machine is to regularly inspect whether the flying probes are worn. If necessary, probes can be cleaned with a recommended cleaner to ensure a clean connection during testing.

Test Program Updates: As circuit designs change, manufacturers need to ensure that flying probe tester programs can handle new test points, SMD components, or other changes on the board.

Calibration: Over time, components in testers may change position, resulting in inaccurate test results or undetectable defects. Calibration is performed regularly according to manufacturers’ guidelines to ensure accurate contact testing and test coverage.

Problems with flying probe testers may require repair. Common problems include probe failure, test head alignment problems, or test procedure problems. Here are some common steps in the repair process:

Diagnosing the Problem: The first step in repairing a flying probe tester is to diagnose the problem. Check the display of the machine for error messages and make sure all the probes are in the correct position. If the flying probe does not make proper contact with the test point, check whether the probe is worn or the positioning system of the machine is faulty.

Replacing Probes: If the probe is damaged or worn, replace the probe. Make sure the new probe is the same type and size as the original probe.

Recalibrating the System: After completing the repair, recalibrate the flying probe tester to ensure that it is working properly. Calibration ensures that the tester is aligned with the test point and accurately evaluates defects in PCB assembly.

PCBasic offers a full range of assembly services, including two-sided, three-layer and multilayer PCB assembly, flexible board (FPC) assembly, HDI high-density interconnect board assembly, and high-frequency board assembly. At the same time, PCBasic also provides SMT and DIP hybrid assembly, providing precision electronics assembly, automated production line assembly and PCB assembly services for various package types.

Through the introduction of advanced flying probe testing, PCBasic ensures the high-quality standards of every circuit board to meet the needs of various electronic products, including medical, communications, consumer electronics, aerospace and other industries, providing customers with better quality and more reliable products.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.