Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Flying Probe Machine Cost and Efficiency: An Analysis

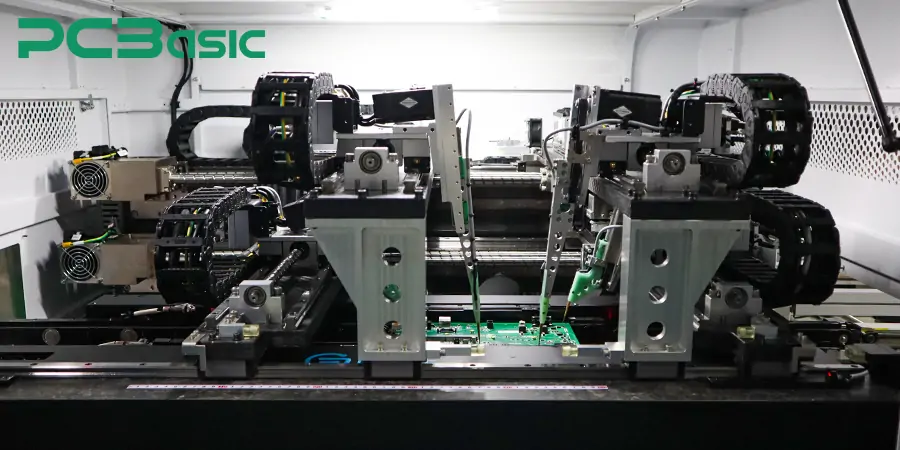

Whether in PCB manufacturing or PCB assembly, testing is an important process to ensure the reliability and functionality of the final product. Today, PCB design is becoming more and more complex, more and more fine, the need for testing is naturally higher. Therefore, in order to meet this demand and provide customers with higher-quality products, PCBasic introduced the flying probe tester machine. This PCB testing equipment is an efficient, low-cost and flexible solution. In this article, we will explore the advantages of flying probe tester in terms of cost and efficiency. Let's take a look!

The flying probe tester is a non-contact automated test system for PCB testing that is capable of identifying electrical faults such as open circuits, short circuits, and component placement errors. Unlike traditional test methods, such as ICT tests that require PCBA test fixtures, flying probe testers use multiple moving probes that "fly" to test points on the PCB (work by moving electrical probes to specific test points on the PCB). If you want to know more about the definition of flying probe machine, please come here. Then, let’s talk about flying probe machine cost and efficiency.

Although buying a flying probe test machine is expensive, the benefits it brings are also very high.

The efficiency brought by the flying probe tester in improving the efficiency of PCB test is significant.

The flying probe tester is ideal for small to medium batch production. The flexibility of the flying probe tester is an ideal solution for low-volume manufacturers who need to test multiple PCBA designs, as it enables quick testing of low-volume production without the need to replace expensive fixtures or make excessive setups.

For manufacturers engaged in high-mix, low-volume production, flying probe machine can handle a variety of PCB designs in different configurations, and are an excellent choice to produce a variety of different PCBS in the production process to save costs and improve efficiency. Welcome to consult PCBasic!

From the above we can see that the flying probe tester is really a good choice to save costs and improve efficiency, and is the ideal test solution for modern PCB manufacturers. From low initial investment to increased flexibility, faster testing and improved accuracy, this approach is cost-effective and efficient for small batch, high-mix production.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.