Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > PCBasic: A Top PCBA Supplier for Power Supply Board Assembly

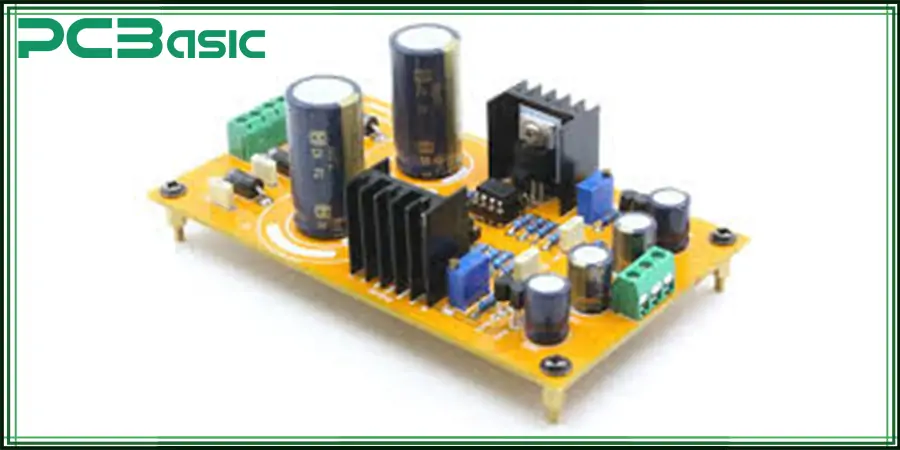

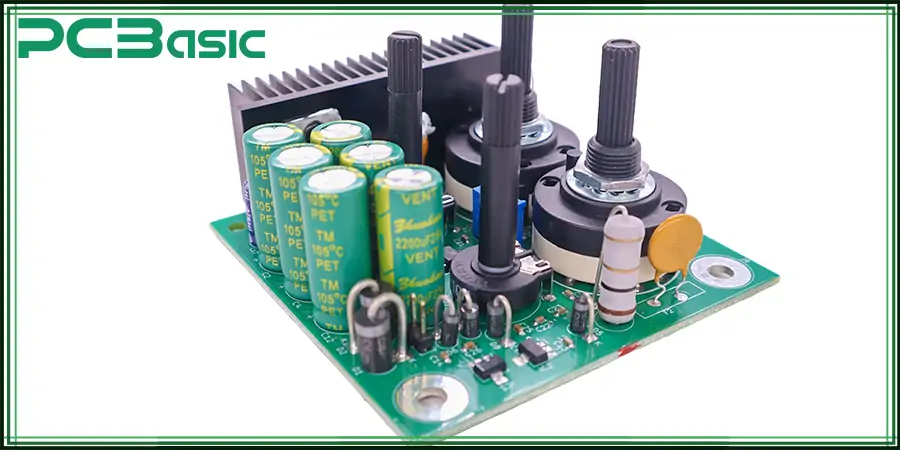

Ever wonder how power is circulated and regulated within connected devices such as laptops, smartphones, and desktops? The power supply board plays a significant role in ensuring the robust transfer of power in all electronic devices at home. PCBasic, a leading supplier of power supply boards, has invested more than 15 years of experience in manufacturing and assembling premium universal power supplies. You can never go wrong with our power supply components. We strive for perfection in our production and assembly process.

This post, therefore, delves into the details of the power supply board you need to know to help you make an informed decision when dealing with power supply circuit boards this year. Let’s get started!

A power supply board is a special electronic component engineered to transform and regulate power to electronic devices. Typically, a power supply circuit board plays a significant role in regulating and controlling power from its incoming source to the targeted connected devices and their motherboard for safe use.

Additionally, power boards are designed with labeling to specify the amount of operating voltage and current each board can hold for proper use in various electronic systems. They are also characterized by protective features such as fuses, which act as protective gear against power overload and prevent harm to power supply components.

Needless to say, these boards are composed of various essential components, facilitating their main function in power supply. Here are some of the components most associated with custom power supply:

Transformers help by stepping up or down voltages, especially in an AC power supply circuit board. Therefore, step-down transformers help mitigate the incoming power to the electronic components to suit the circuit's requirements.

However, you'll only need step-up transformers if you're using high-powered electronic components. The step-up transformers will provide the necessary power voltage for your project.

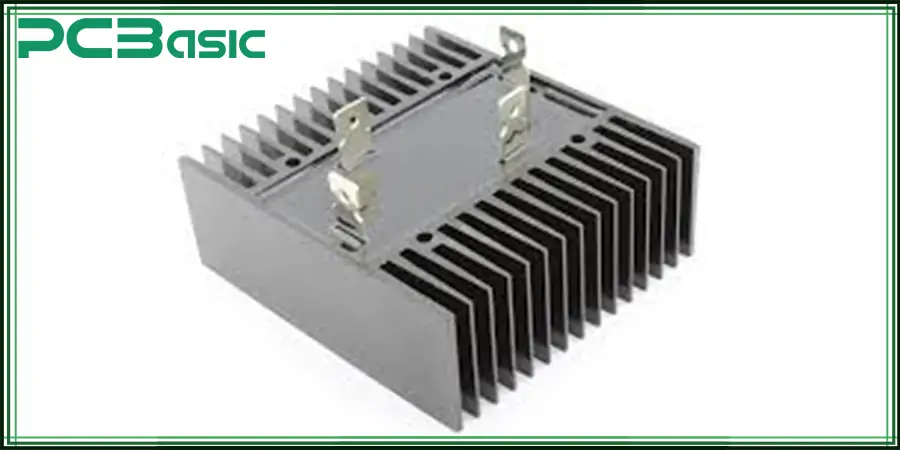

While transformers help in step-up and down, rectifiers, on the other hand, help in voltage conversion from AC voltage to DC voltage. Thus, this power supply component ensures the circuit functions well on the required DC voltage.

Capacitors and inductors fundamentally act as filters to lessen ripple and voltage voices in electronic devices, leading to a seamless and more robust DC output.

Now you know what a power supply circuit board is and the essential components that encompass a power board, right? But how are they assembled for the fishing products? Let’s find out!

Power supply board assembly is considered significant in the manufacturing of electronic components. Generally, the assembly process of a power supply board entails combining different electronic components onto a PCB, commonly known as a Printed Circuit Board, to form an operational circuit for a particular purpose.

Are you aware that well-executed power board assembly processes not only promote the efficacy of electronic devices but also play a monumental role in ensuring their longevity in use?

The first assembly process of PCB manufacturing involves careful planning and designing, often including choosing the appropriate materials needed for PCB production. Some of the popular components needed before the assembly process begins include the following:

· Resistors

· Capacitors

· Microcontrollers

Here's a breakdown of the power supply board assembly process:

Printed circuit board production begins with solder paste application after planning and designing have been considered. Solder paste application is vital in PCB assembling for Surface Mount Technology (SMT).

This stage involves the following:

· Placement of stencil over printed circuit board followed by solder paste application.

· Dispensers and solder paste are used to strengthen the application.

The solder paste application stage helps strengthen the connection between the printed circuit board and the other components used in the assembling process.

Once the solder paste application is done, placement of the components on the board follows suit. The placement of components on the board is a meticulous process that involves the following:

· Surface Mount Technology is used, where pick-and-place robots precisely place components on the board.

· Manual insertion is used to insert a hole through the insertion of the components onto the board.

It is advisable to ensure precision at this stage, as it will determine the proper functioning of the final printed circuit board.

Reflow soldering is crucial after placing components on the board to establish a firm connection between them. Therefore, a printed circuit board passes through a reflow oven with a certain temperature profile in reflow soldering.

This will involve:

· Preheat

· Thermal soak

· Reflow

· Cooling

After the above sub-processes have taken place, the solder paste will undergo the following: melting, solidification, and the creation of strong solder joints.

Inspection and quality control come after reflow soldering to examine the quality of the printed circuit board for use in homes or businesses. This stage ensures the PCB assembly process is executed according to PCB manufacturing standards.

Therefore, cameras and software detect flaws in the assembly process, such as solder bridges or misalignments of the solder joints. X-rays are also conducted to examine hidden solder joints. Conversely, trained technicians perform manual inspections to check for any common mistakes.

Final checking accords complete confidence in the entire printing circuit board assembly process. Therefore, PCBA is announced as ready once the final checking has been implemented. This is done in the following ways:

· Final visual checking

· Function testing of the board to ensure its operational features are effective.

After the final inspection, this gives room for PCBA packaging and shipping.

Here are some core applications of a universal power supply board:

· Used in communication systems to offer robust DC to circuits, including towers, switches, routers, and cellular.

· Power boards aid in efficient energy transfer, especially in vehicles, boats, and aircraft.

· Used in high-powered medical equipment for power precision during implants, surgeries, etc.

PCBasic’s, as a leading power supply supplier is dedicated to offering comprehensive assembly services to meet everyone desires and preferences. The following strategies instruct PCBasic’s power supply board assembly services:

Our committed team at PCBasic is characterized by professional and skilled personnel responsible for designing and producing high quality and pocket-friendly power supply circuit boards. Conversely, we are dedicated to meeting every client’s needs and tastes based on their specifications, thus ensuring the nothing but the best.

At PCBasic, we ensure our power supply circuit board goes through strict and thorough quality assurance. Our power boards undergo rigorous testing to adhere to client specifications and international standards.

Understanding the details of power boards in power transfer in electronic components is essential. The power supply circuit board regulates and provides power to the motherboards for safe use. This makes them effective in communication systems, medical equipment, and transportation, among other applications. If you're looking for premium, pocket-friendly power supply boards for your business, look no further; PCBasic has you covered.

Contact us today for power supply circuit boards!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.