Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > CNC Routing Services by PCBasic

Creating a design means you can visualize your idea. Programming CNC routers becomes essential because of difficult design shapes or distinctive metal cuts. Transforming your concept into reality while minimizing mistakes presents itself as a challenge. A great way is CNC routing.

PCBasic operates machines using computers that perform precise cuts on materials. The CNC routing services performed by PCBasic deliver professional-quality solutions for your work needs. CNC routing functions as a valuable technique for producing accurate products that require replication.

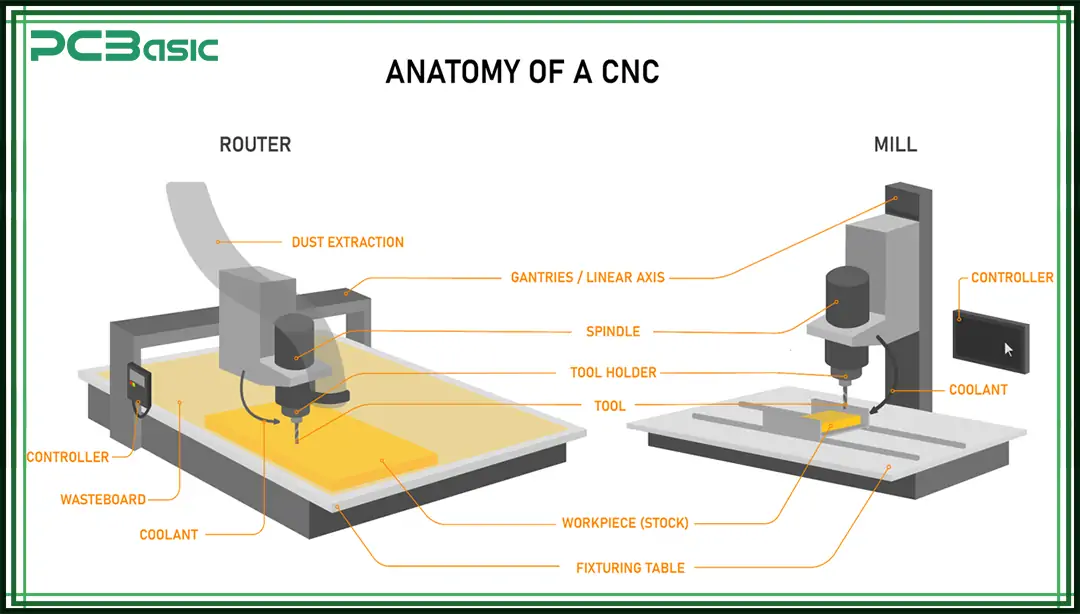

CNC stands for Computer Numerical Control, allowing CNC routing, which is the process of cutting computer-operated machines. A computer program functions as the director that informs the cutting tool about its operations.

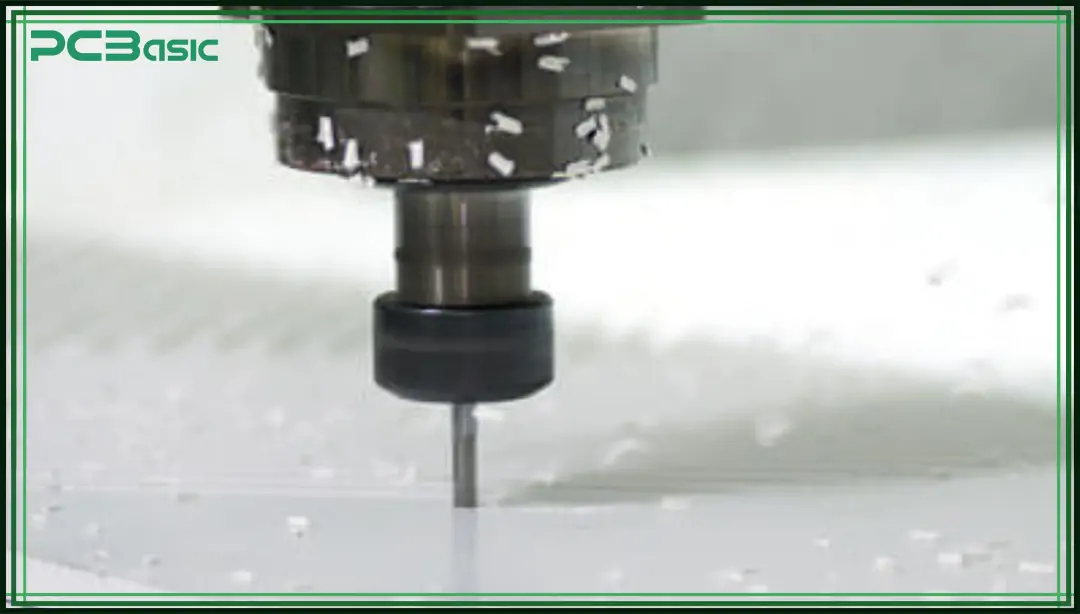

A Computer Numerical Control machine functions as an ultra-precise instrument that interprets digital sketches to perform precise material cutting. The machine contains a rotary cutting component. The instrument operates to cut materials in many different directions. Using this technique provides repeated performance for both fine designs and square corners.

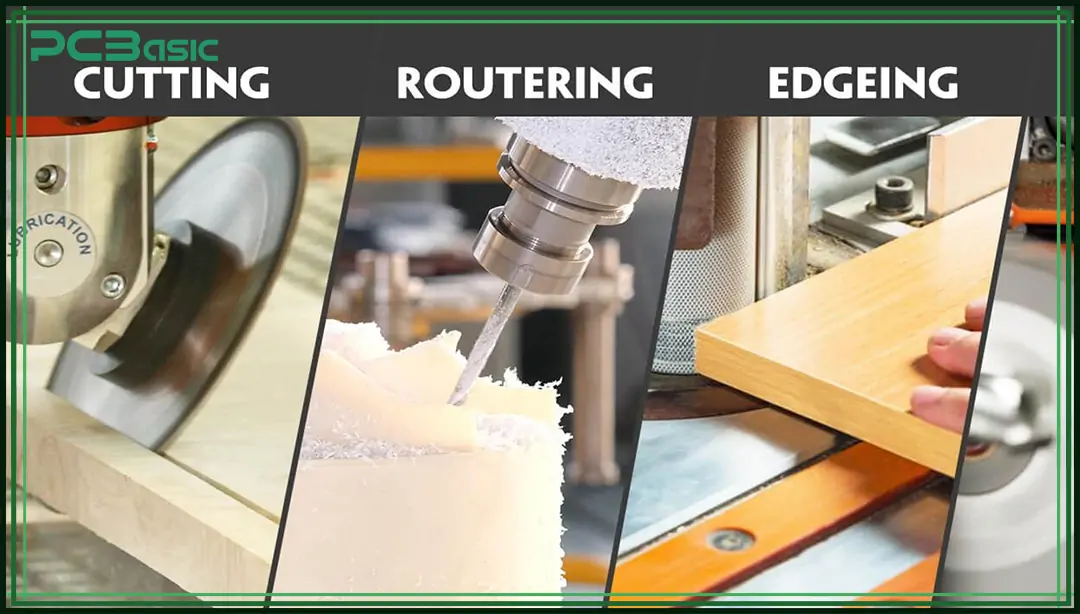

The best CNC machining processes exist in CNC routing, which enables the cutting of different materials. You can cut things like:

Plywood, MDF, and other types of hard wood and soft wood. Through CNC routing users achieve versatility in working with wood materials since the material cuts easily and produces attractive results. The process of CNC wood routing will drive your interest toward making items such as furniture and signs.

CNC routers operate on acrylic as well as PVC and polycarbonate along with numerous kinds of plastic materials while preserving the purity of finished edges. CNC machining suits plastic production because it enables precise cutting and detailed molding of the material.

The processing operation of CNC routing is suitable for cutting both aluminum sheets and aluminum bars. The automotive and aviation businesses benefit from this feature because they need strong lightweight components.

A CNC router produces quick foam-cutting operations that include both hard foam and foam board materials. The machine frequently handles packaging duties as well as sign fabrication and model construction tasks.

The process of CNC routing fiberglass materials requires customized tools and specific procedures which may be required.

CNC routing enables cutting through diverse materials; thus, it serves many different industrial sectors.

Requirements determining why you should choose CNC routing services instead of hand-cutting methods. The following list identifies multiple reasons.

The precision aspect of CNC routers enables them to execute cuts with extremely few dimensions. Your designed cuts will appear exactly identical to the ones you created. Engineers require that parts conform exactly to one another.

Any programmed part design becomes easy to duplicate by CNC machines. A large number of identically produced items easily become feasible because of this benefit.

The combination of CNC routing enables users to produce complex designs, which would make hand craftsmanship unfeasible and extremely difficult. Hand-cutting techniques produce predictable poor outcomes in which complex forms cannot be reproduced exactly the same way during every single attempt.

The rapid performance of CNC machines beats manual drawing operations entirely by saving hours of production time and cutting costs.

The CNC process is precise, so it can achieve maximum efficiency. The automated process results in better material efficiency because the risk of human errors is reduced during manufacturing.

A CNC router produces identical pieces since all its output matches the previous piece. The method protects product consistency across all manufactured items.

The benefits that make CNC routing appealing to numerous users can be found in the following lines.

A combination of its diverse performance along with precise accuracy makes CNC routing services work for many commercial applications in different industrial sectors:

Your business makes regular custom signages and logos together with display items by using wood and plastic materials.

The modern furniture manufacturing industry heavily depends on CNC routing for both its refined decorations and precision fitment of components.

A proper operation requires exact and uniform cuts of each cabinet door and frame component.

Creating exact initial models of products helps in both their testing and their enhancement phases.

The art of building scaled or full-size objects for architectural designs falls under Model Making and Models for Architecture.

The models you create must be precise and detailed before you show them to others.

The process of CNC routing starts with the following detailed sequence to implement engineering designs.

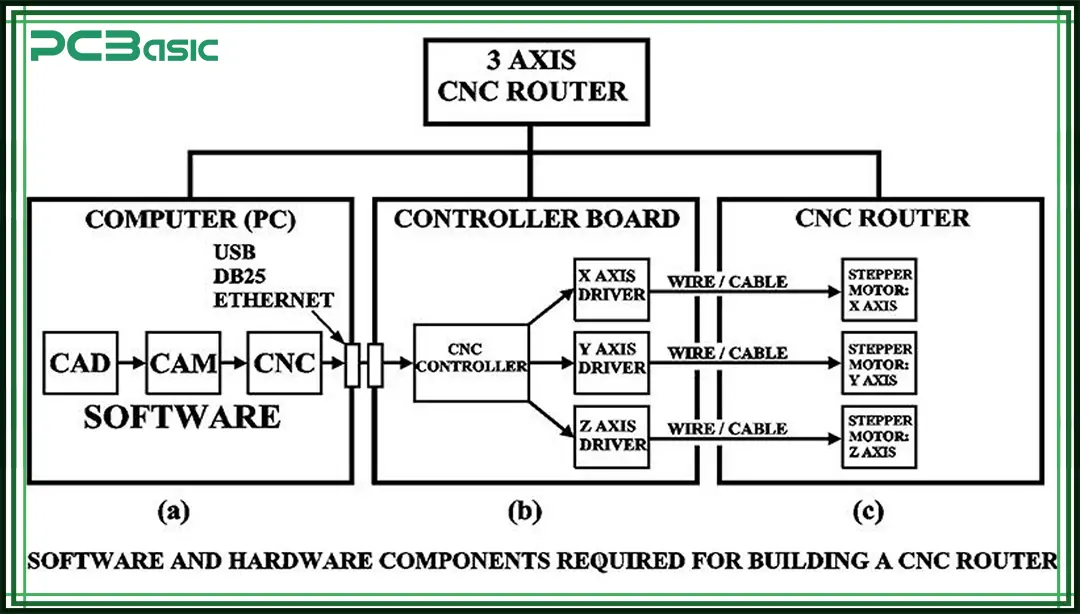

Computer software tools enable you to design your projects through CAD applications. Draw the actual shape and dimensions of the cutting materials you wish to create until this point. Engineers always start with excellent planning according to their knowledge base. The program offers two options for design software including AutoCAD and SolidWorks.

The design work involves drawing the details about dimensions and the positions of any cuts or holes. An incorrect design will result in the same level of incorrectness in the final product. Concentrate on your work while confirming that every aspect of your design matches correctly.

After finishing your design, you should move it to CAM software programming for the next step. The CNC machine receives design instructions through this software program. The CAM software generates all required toolpaths.

An example of a toolpath for a cutting tool. Good toolpaths produce both efficient cutting operations along with excellent results. With the program, you provide instructions for cutting depth and speed operations alongside setting the cutting tool's spinning speed. You can accomplish the ideal design by instructing the tool through different movement settings in your experimentation process.

Before operating it, you need to configure the CNC machine system. You set your material, such as wood or plastic, inside the machine for processing. The material should have a clamp that is secure enough to prevent movement. The correct cutting tool, known as the router bit, becomes your selection at this moment.

The machine offers specialized cutters for processing different materials when making linear or curved cuts.

You will then transfer the program that the CAM software created into the CNC machine's computer system. This computer runs the machine. Before initiating operation, the machine operator checks for safe conditions. A CNC machine needs to press the start button to start the cutting process.

At the first moment, observe how the cutting tool moves to verify its correct placement on the material. All points in this stage work to avoid errors from occurring.

During this period, the machine executes actual cutting operations. A CNC router runs its operations based on the programmed tool path instructions. The router bit operates at high speed as it moves right and down throughout the operation. The device removes material in small portions until it produces your intended shape.

You will observe the machine performing successive shallow cuts before completing a full penetration on thick pieces of material. Watching your computer model transform into a tangible physical item is what makes this accomplishment memorable to you.

Additional work might be necessary on your part after the CNC router is completed. The required finishing steps include clearing away positioning support materials while making the raw edges smooth through sanding and dust removal. Different projects require painters to apply finishes through coatings as finishing steps.

A final touch is essential because it improves visual appeal. Understanding how much work belongs to automation systems and how much needs your manual intervention to achieve the best results represents your key objective. Albeit cut by the machine it is not completely finished at this stage.

Why selecting a vendor for CNC routing matters to your success. Finding the correct partner for your project remains essential since it leads to project achievement. Quality, together with trust, form the leading principles of PCBasic operations. PCBasic offers an ideal solution that suits all your CNC routing requirements.

PCBasic brings substantial experience to the table and comprehends all material behaviors when using CNC routing methods. The team at PCBasic understands all necessary measures to handle your projects with accuracy.

Every CNC cutting service at our facility uses the most up-to-date CNC routing equipment available. Modern CNC machines enable precise and speed-enhanced cuts of different materials.

According to previous statements CNC routing operates effectively for many different materials. The team at PCBasic possesses capabilities and equipment to operate on wood pieces in addition to plastics and aluminum and other materials.

PCBasic approaches every piece of work as a singular entity. Custom CNC Routing Service provides solutions through PCBasic.

PCBasic guarantees high-quality results. The processes established to ensure your parts match exactly what you expect during production run a number of tests.

According to our understanding, the time-sensitive delivery of parts remains our highest business priority at PCBasic. The PCBasic team works toward solving projects promptly while meeting their deadlines.

Our excellent price rates for CNC routing services do not affect the quality of work we deliver.

The selection of PCBasic means selecting an organization that is fully committed to delivering superior CNC services.

The production of exact and recurring parts from different materials achieves the highest standards through CNC routing services. The application enables the creation of signs together with machine parts, and new discoveries about its capabilities emerge daily. PCBasic provides quality-based CNC cutting services along with additional services between them. At every step of precision work, we focus on delivering perfect results for every detail.

Assembly Enquiry

Instant Quote