Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What Is Surface Finish in PCB Manufacturing?

Without question, the easiest way to think about PCB manufacturing (printed circuit boards) is to think about the big parts, such as the circuits, connections, and components. But there's one crucial aspect that plays a major role in how well your PCB performs: the surface finish.

In PCB manufacturing, the copper of the board is exposed and needs protection. Why? For some reason (possibly because it's copper), copper tends to oxidize, so it doesn't perform too well and can interfere when you're trying to solder it later. This copper exposed by laser had a surface finish because it needed to prevent that copper from oxidizing and making the soldering of components onto the board practically impossible. In this guide, we will show you the most common types of PCB surface finishes and shall assist you with which one might be the right fit for your project.

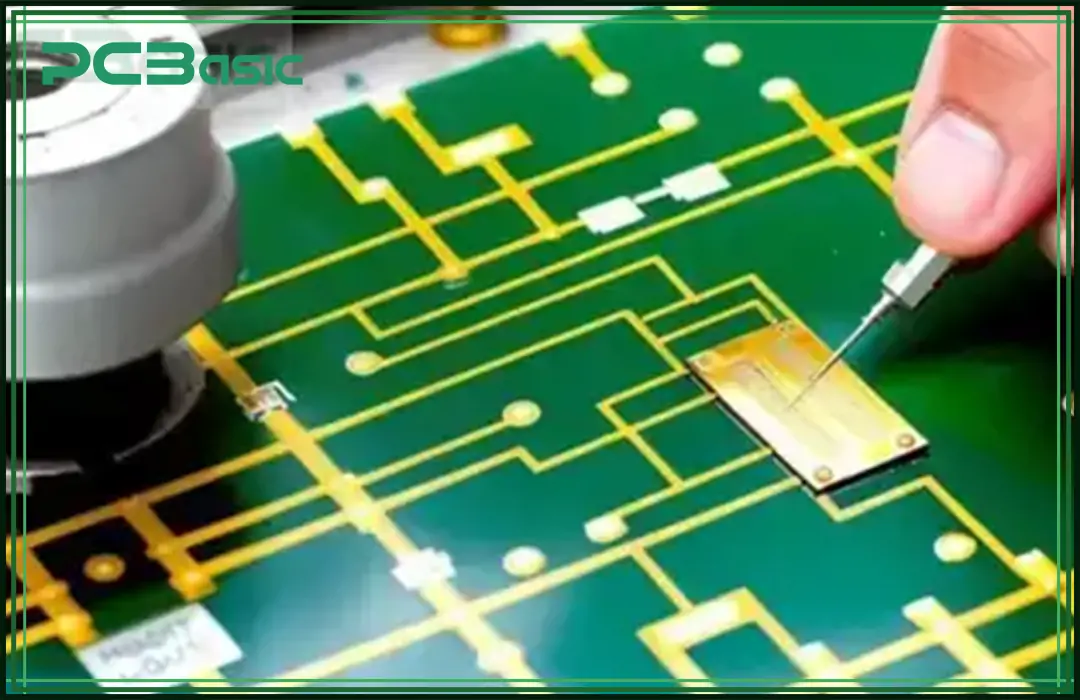

Before anything further, it's worth understanding what surface finishes are. The protective layer refers to a surface finish over copper pads, forming a surface finish layer on PCB. For example, the copper pads of the PCB are locations at which electronic components, i.e., resistors, capacitors, microchips, etc, are soldered. The surface finish keeps the copper from ever reacting with the air to begin the reaction cycle of corrosion. It also ensures that components can indeed be soldered on properly.

Here’s the thing: you might wonder why anyone would put so much work into the surface finish when it comes to making a PCB. Isn't it more important what the circuits are designed like, or the quality of the components? That’s important too but if that surface finish’s not good the overall performance of the PCB could suffer.

Prevents Oxidation:

We mentioned that copper is very oxidizable when exposed to air. Copper can then be oxidized, creating a layer that prevents good electrode conductivity on the copper.

Makes Soldering Easier:

A good surface finish is achieved by a smooth, even surface for soldering. The PCB components are attached by soldering.

Improves Reliability:

In the long run a PCB with a good surface finish applied will be more reliable. The finish protects the board from environmental factors, wear and tear, and damage during the assembly process.

Durability:

Surface finishes are developed to encourage the durability of the PCB. The finish provides protection to the copper from oxidation and wear to allow the PCB to handle multiple soldering cycles and have good performance even in different environments.

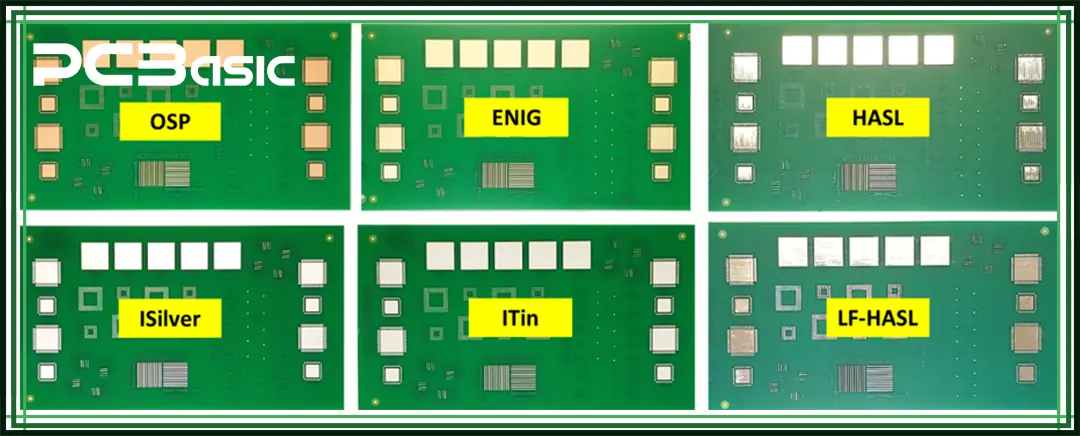

Once you know why the surface finishes matter, we will look at the most common finishes used for PCB manufacturing. There are pros and cons to each type and the optimal choice depends on what your project needs.

One of the oldest and most popular PCB manufacturing surface finishes is Hot Air Solder Leveling (HASL). In HASL (Hot Air Solder Leveling), the PCB is dipped into molten solder containing either tin and lead or just tin (lead-free HASL).

Advantages of HASL:

Cost-effective

Good shelf life

Easily reworkable

Disadvantages of HASL:

Uneven surface

Not suitable for fine-pitch components

Not RoHS compliant (if leaded)

ENIG is a premium surface finish where nickel is applied, followed by a thin layer of gold over the copper pads. The output is a smooth, flat surface that is ideal for complex PCBs with small components and then runs through a controlled process.

Advantages of ENIG:

Flat, smooth surface

Excellent corrosion resistance

RoHS compliant

Disadvantages of ENIG:

More expensive

Black pad issue

The improved version of ENIG is ENEPIG. In this finish, an atomic layer of palladium is deposited between the nickel and gold layers. As well as excellent protection from corrosion, this also makes the finish perfect for wire bonding, an industrial process that is particularly common in high-performance applications.

Advantages of ENEPIG:

Great for wire bonding

Very reliable

No black pad issue

High cost

Less common

|

Feature |

HASL Finish |

ENIG Surface Finish |

ENIGPIG |

|

Cost |

Low |

Medium |

High |

|

Surface Flatness |

Uneven |

Flat |

Flat |

|

Oxidation Resistance |

Moderate |

Excellent |

Excellent |

|

Fine-Pitch Suitability |

Poor |

Excellent |

Excellent |

|

Durability |

Good |

Good |

Excellent |

It’s an organic finish that protects the copper pads with a thin organic layer. It’s the least expensive finish and it’s often used in consumer electronics where there will be a long-term durability disadvantage.

Advantages of OSP:

Very affordable

Flat surface

Environmentally friendly

Disadvantages of OSP:

Short shelf life

Not suitable for complex designs

A Metal finish called Immersion Silver is a thin layer of silver over the copper pads. The price and performance are well in line with this middle range: good electrical conductivity and a smooth surface.

Advantages of Immersion Silver:

Good for high-frequency applications

Flat surface

RoHS compliant

Disadvantages of Immersion Silver:

Tarnishing

Not as durable

Immersion tin is a PCB surface finish process where the copper pads on the circuit board are immersed in a special chemical solution, causing a thin layer of tin to form automatically on the surface of the pads. This tin coating not only covers the entire surface of the pads but also ensures the coating is smooth and uniform. The purpose of this process is to protect the copper pads from oxidation while also providing better solderability during component assembly. It is especially suitable for circuit boards with fine-pitch components that require a highly flat surface.

Advantages of Immersion Tin:

Offers a flat surface ideal for fine-pitch components

Cost-effective for high-volume production

Disadvantages of Immersion Tin:

Susceptible to tin whiskers

Limited shelf life compared to other types of surface finishes

Choosing the right PCB surface finish requires considering several important factors to ensure the board's performance and longevity.

• Component density and type

If the PCB contains many small or high-density electronic components, selecting a surface finish with a smooth surface, such as ENIG or immersion gold, will improve solderability.

• Environmental exposure

If the PCB will be used in humid, high-temperature, or corrosive environments, a surface finish with strong oxidation resistance, like ENIG or OSP, is recommended.

• Budget constraints

Different surface finishes vary in cost. HASL PCB and lead-free HASL are low-cost options suitable for mass production, whereas ENIG and immersion gold are more expensive but offer higher reliability.

• RoHS compliance requirements

If the product must meet environmental regulations, choosing lead-free HASL or other RoHS-compliant surface finishes, such as ENIG or OSP, is necessary.

For cost-effective projects, HASL PCB or lead-free HASL are practical choices, making them suitable for general electronic manufacturing.

For enhanced durability and reliability, especially for long-term use or high-performance applications, ENIG surface finish or immersion gold PCB are preferred, as they provide better oxidation resistance and solderability.

If the PCB design includes fine-pitch components (such as small pads or BGA packaging), a highly flat surface is essential. In this case, immersion silver or immersion tin would be the best option.

Choosing the right surface finish for your PCB is a critical step in the manufacturing process. Whether you’re looking for a cost-effective option like HASL or a high-performance finish like ENEPIG, understanding the pros and cons of each type will help you make the best decision for your project.

With the right surface finish, your PCB will not only perform better but also last longer, ultimately contributing to the success of your final product.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.