Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is an SMT Stencil?

The manufacturing of PCB boards involves a lot of processes, including making a board and different techniques for component connections. An SMT stencil is used for the PCB assembly process. SMT stands for Surface Mount Technology, and SMT stencils is now considered as the main tool of PCB board production. In this method, solder paste is applied to the board for connection of SMD devices or components. This process involves making a quality board.

Here we will learn how this process is applied and its features. Let's get started.

A PCB stencil is a stainless steel foil that has holes made with lasers according to the leads or pins of components connected to the PCB board. This process helps to apply solder paste on the PCB board. After that, the PCB board faces different processes such as the connection of SMDs, soldering, automated optical imaging, through the hole, and at last, wave soldering.

The connection of SMD components on the PCB board is sensitive work since they are small in size and need proper accuracy and handling. So an SMT stencil is the best option for the connection of these components on boards without any error or inefficiency.

SMT stencils are made according to the PCB structure, and solder paste is applied on the board. When it dries, connect components on boards.

An SMT stencil is a thin metallic sheet that is employed for the SMT process and helps provide the best SMT soldering. Using this method, we can apply solder paste to PCB board SMD pads that help to perform errorless reflow soldering processes.

Designing Process

● Different tools for designing SMT stencils are available, such as CAD, which can be used for making the PCB layout. This designed layout comes with pad configurations at a proper location that helps to apply solder paste. In this step, different dimensional features of the stencil, such as thickness, diameters, and layout according to board component connection, are defined.

Select Required Materials

● There are different materials used for stencils based on applications and project demand, but the most commonly used are nickel or steel. The thickness of this material is in the range of 0.1mm to 0.25mm.

Etching Process

● The design made in the first step was used to cut stencils with the use of a high-accuracy laser. If the stencil material has a coating of photoresist, the chemical etching process is used for cutting according to design.

Stencil Cleaning

● Removing the dust particles on the surface of the stencil makes it clean.

Stencil Surface Treatment

● The polishing of the stencil surface is done to remove solder paste sticking and make it reliable for a board where it has to be used.

Inspection and packaging

● In this last step, a final inspection is performed to check that all dimensions are according to the requirements and make the packages for delivery.

Here are some main advantages of using SMT stencils:

1. The use of SMT stencils with solder paste reduces the chances of short circuits, and if there is no SMT, you will have a high chance of short circuits on your board.

2. The use of SMT stencils with laser cutting provides uniform layers of solder paste on board without gaps and provides smooth soldering.

3. SMT stencils provide smooth pad walls for the proper design of the board, and each board manufactures such a type of layout.

4. The other benefit is that it provides errorless and smooth apertures for the board.

5. This process also provides the accurate location of the pad at the required point, and it helps provide accuracy at the time of printing the laser-cut stencil used.

|

SMT Stencil Type |

Details |

Advantages |

Shortcomings |

|

Framed SMT Stencil |

This type of stencil is fixed with a frame and stretched to provide accurate printing results. |

Durable, reliable, used for bulk production, and comes with a smooth aperture |

It is high-cost compared to frameless stencils and has less flexibility for different projects. |

|

Frameless SMT Stencil |

This stencil is not fixed with a frame and has reusable features for different frames. |

Cost-effective, covers low space, used for low-volume production |

It shows low accuracy since it is manually applied and needs flexibility for different circuit connections. |

|

Prototype SMT Stencil |

This stencil type provides customization features based on CAD or Gerber files of prototypes. |

It reduces the time for the PCBA process and errors at the time of printing. It does not need any frame and is used for manual processes. |

It is not used for bulk production, and since it needed some changes frequently. |

|

Electroformed SMT Stencil |

This stencil type is based on nickel and the electroforming process used for making this stencil. It is normally used for µBGAs. |

Its main features are pitch and high accuracy. Good for printing and durable nature. Used for complex types of boards |

Since it involves complex manufacturing processes that make it costly. It is not used for low-volume |

|

Kapton Stencil |

Kapton materials are used since it is best for performing the hand-soldering process. |

It is best to use for hand printing and is also flexible for prototyping. |

It is not reliable as metallic stencils provide features and do not have features to handle bulk volume production. |

A stencil is a thin sheet made with different metals, such as aluminum or stainless steel. It has small apertures that help to print the design on the board.

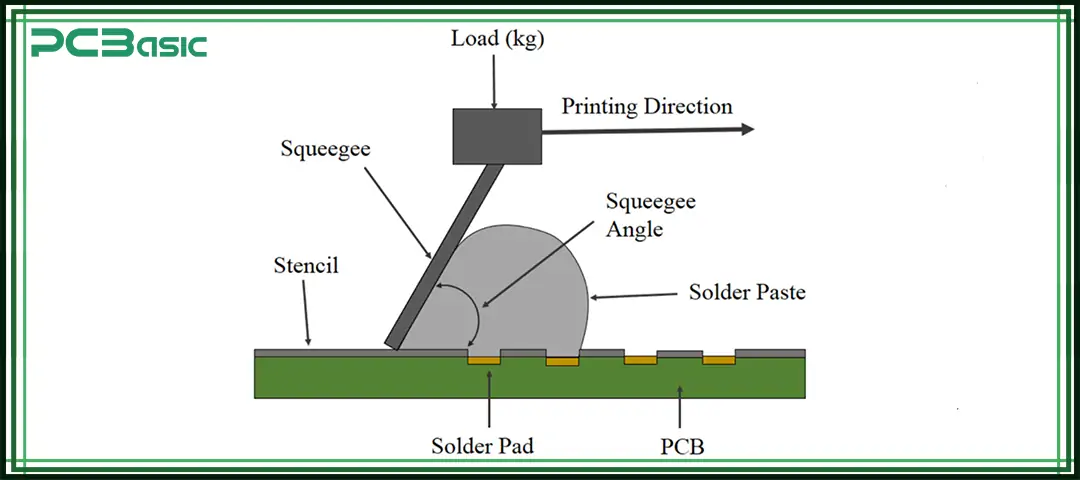

For application on board, the stencil is configured on the upper surface of the board on the frame. Then solder paste is applied to the stencil smoothly. From passing through the apertures, solder pastes get dimensions according to the design on board. The quantity of applied paste is controlled through small-sized holes and helps to provide an accurate soldering process for the board.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

● First of all, check the thickness of the stencil, which must be according to the connected components, packaging type, and size, as well as the space between the pins of components.

● Use materials that come with durability, longer working life, and hardness with corrosion resistance. Normally stainless steel and copper are used for laser-cut SMT stencils. Stainless steel is used since it provides a longer working life and has hardness features, while copper provides good electrical conductivity features.

● Before selecting a stencil, you must check the dimensions of the board. Normally, stencils are selected based on board shape and space, such as line width and line spacing.

For PCB assembly with other factors, the importance of the SMT stencil cannot be denied. It has features for controlling deposited solder pastes on board and helps to connect components on board properly. If the accurate type and dimensions of SMT stencils are used, that helps to make our board with quality and according to project requirements. This process has now become an important backbone for getting quality solder paste deposition for the SMT process.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.