Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is Quad Flat Package (QFP)?

Are you curious about QFP packages? See how these compact, efficient designs help electronics run smoothly. Learn more about this modern technology for your devices!

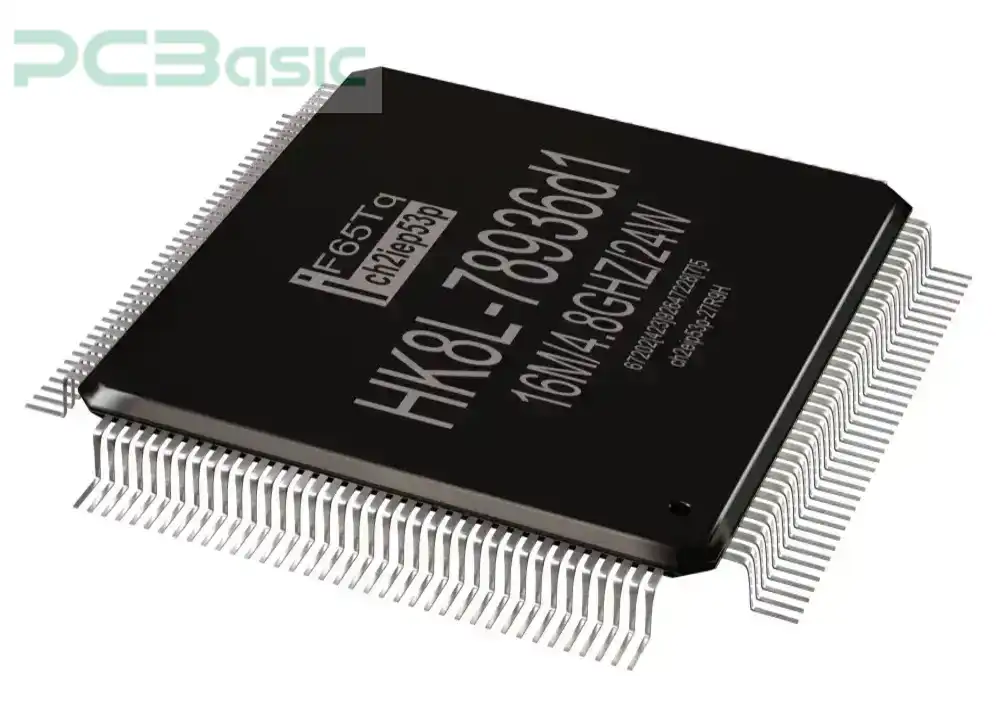

QFP is commonly known as the Quad Flat Package.It's one of the surface-mount packages that are used to house electronic parts, including microcontrollers and processors. QF packages have smooth surfaces, either square or rectangular shapes have protruding leads on every corner, so giving them the name "quad" layout. These leads are systematized into a grid arrangement, making it easy to attach printed circuit board components to them.

The package design finds its application in a variety of circuits, including not only digital logic, such as microprocessors or gate arrays, but also in analog devices like video tape recorders and audio equipment. They come in different sizes depending on the spacing between pins, which ranges from 1mm, 0.8mm, 0.65mm, 0.5mm, 0.4mm to 0.3mm. A maximum total number of 304 pins can be used in a size of 0.65mm.

QFP packages aren’t just used for high-tech things like computers and communication equipment; they can also be found in many different places. These packages are present in consumer electronics, automobile electronics, as well as industrial control systems. If you choose the right type of package then it will enhance your circuit design functions.

QFP packages have a number of essential characteristics. They have a somewhat rough surface, which makes them more reliable. They come with a broad frame that is compatible with matrix lead frames. In order to create small, accurate pitches, the QFP package uses precise stamping tools combined with precision metal bending processes

They are common in the electronics industry, especially for telecommunication gears, consumer electronics, and industrial control PCBs. Some examples of devices that employ these types of packages include:

● Microprocessors

● Digital Signal Processors (DSPs)

● Memory Chips

● Field Programmable Gate Arrays (FPGAs)

● Power Management Integrated Circuits

● Audio and Video Processing ICs

OFP packages come in different types and each package is designed with specific needs. All they provide on their cross-section is because they are very small, thus making them suitable for this purpose. This first paragraph also helps you understand that you ought to make sure that you look at all designs before selecting one; otherwise, you will be stuck with an inappropriate thing as two things cannot be the same.

Here are a few common types of QFP packag

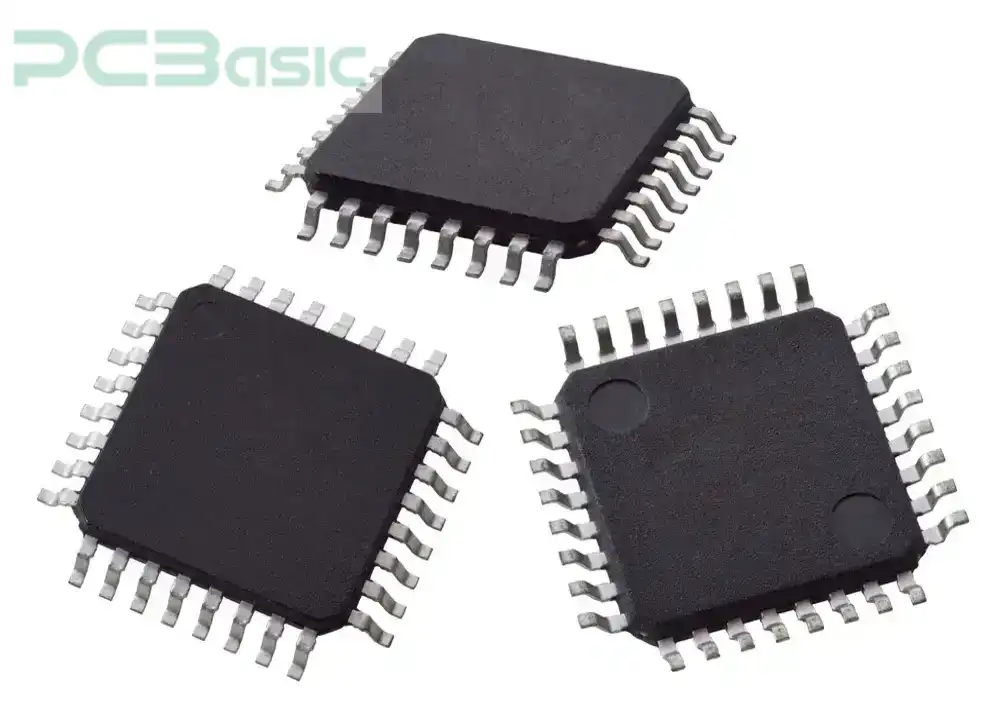

TQFP is a type of surface mount package made to solve different problems for engineers, designers, and component connectors alike. One of its greatest advantages is allowing more components to fit into the same size circuit board leading to smaller and thinner designs and portability improvement. Various types of IC semiconductor technologies can utilize this package particularly well.

As far as shape goes, they have four gull-wing leads on each side which makes them stand out from other packages, such as lqfp vs tqfp, because they are thinner than these two.

Many electronic systems such as computers, video and audio processors, phone and data communicators, Ethernet and ISDN boards, set-top boxes, or automobile electronics can use the Thin Quad Flat Package (TQFP). It ensures that the various performance needs in these industries are satisfied.

TQFP Package Overview

Shape of Package: The TQFP has a square-shaped body with pins arranged horizontally at its base. It can accommodate anything between 32 and over 100 pins.

Arrangement of Pins: The distance between the pins is normally uniform, usually 0.5 mm or 0.8 mm apart. The spacing of 0.5 mm is used for packages with many pins, while that of 0.8 mm is used for those with fewer pins.

Thickness of Package: The thickness of the TQFP package varies depending on its size and requirements from PCBA company, within the range of generally 1.4mm and 1.6mm.

Soldering Pads: Pins on TQFP connect to PCB through soldering pads. These pads can either be leaded or lead-free, whereas the latter is more eco-friendly in compliance with RoHS standards.

Heat Management: A high number of pins can lead to heat build-up, making it difficult to disperse heat. Therefore, FS Technology suggests the use of heat dissipation pads or radiators in dealing with this heat problem.

Installation: Most TQFP packages are installed by SMT (Surface-Mount Technology). During installation, hot air or a reflow oven is employed for melting and heating solder paste to securely attach IC TQFP onto PCB boards.

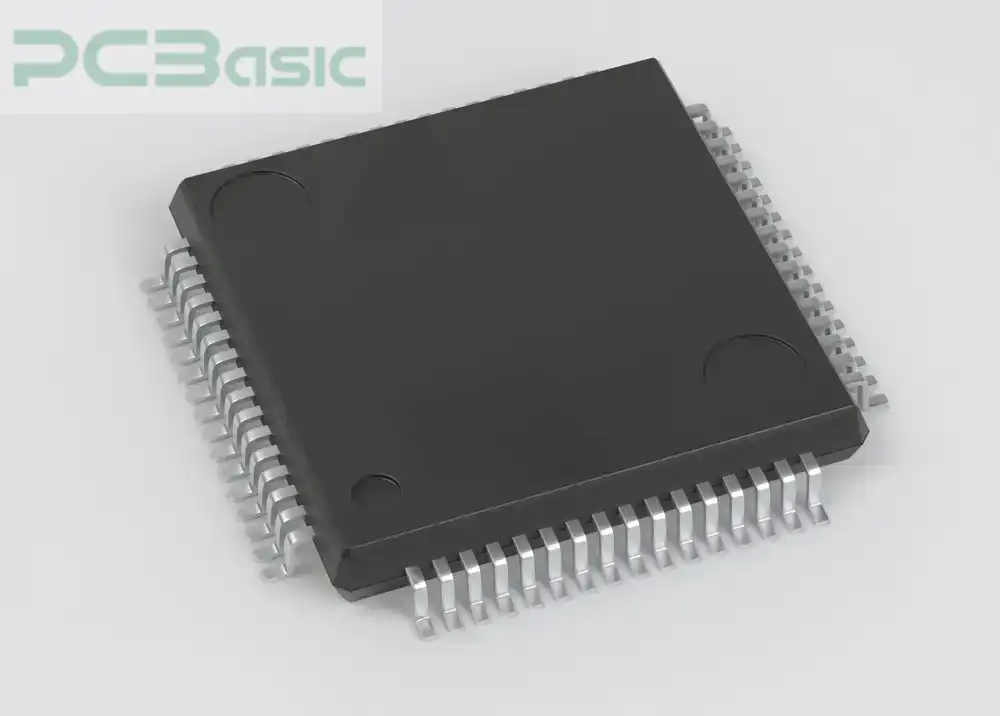

The Low Profile Quad Flat Package (LQFP) is a surface-mount IC package type having pads around all 4 sides. It is made in a way that bears similar advantages exhibited by metric TQFP but with a thinner design and leads with a standard footprint.

The body thickness of LQFP ranges from 1.2mm to 1.7mm hence making it slenderer than other packages. A dot indicates where to start numbering pins, and they are numbered in a counter-clockwise direction.

Avoid placing double-sided packages having exposed pads directly opposite each other during assembly so as not to get stiffened joints that lead to fast wearing out of solder joints in them.

TQFP and LQFP packages bear many resemblances yet they have principal differences.

Height is a key difference between TQFP and LQFP packages. Normally, TQFPs are slightly thicker than LQFPs ranging from 0.8mm to 1.0mm, whereas usually, LQFPs are thinner than TQFPs so that they can be less or equal to 1.0mm. This thickness differential may have an impact on the size of your device design.

Because the LQFP package is lower in profile, hence it helps in better heat dissipation. Thus where heat control is largely critical, it should be noted that LQFP is the preferred option. Memory temperatures during operation are well absorbed by TQFP, and thus, it regards its ability to stay cool over time.

TQFP package is a good fit for applications that do not necessarily require a low profile but would prefer it; nonetheless, space is left for additional functions since they have more thicknesses and are mostly used in microcontrollers and FPGAs (Field-Programmable Gate Arrays).

In contrast, LQFP packages are preferred in small electronic devices like mobile phones, tablets, and other portable devices that call for lightweight designs taking the least possible area.

TQFP and LQFP packages differ in their number of leads, although there are minor variations on lead pitch, also affecting component placement density on a PCB.

Additional Features: The tall design of TQFP (Thin Quad Flat Package) has more pins which can accommodate intricate circuits thus making it appropriate for high-end electronic designs.

Versatile Application: Fitting larger components would be easy owing to its ample space hence ideal for bigger electronic projects.

User-Friendly: TQFP being bigger makes its usage while assembling simple, thus reducing probable errors occurrence.

.These days, we need to save space in our gadgets. For this reason, the LQFP (Low-Profile Quad Flat Package) is the best option as it is slim.

The way this device manages heat is quite impressive as it not only allows fast heat dissipation but also serves to keep the temperatures down.

LQFP is shorter and hence can make a device lighter, which is convenient for smartphones as well as other devices that require a lighter weight overall

With the rapid advancement in large-scale integrated circuits, especially with the widespread use of ASICs (Application-Specific Integrated Circuits), chip pins are becoming more numerous and closely spaced.

To meet this growing need, the QFP (Quad Flat Package) was created as a new type of packaging for surface-mount ICs with smaller pin spacing. The qfp electronics package is designed to handle the increasing capacity of ICs and the need for more input/output connections.

What are the characteristics of your training data?

One major benefit of QFP electronics designs is their high pin density. Pins arranged on all sides can allow altogether a great deal of connections over a small area. This is particularly important in modern electronics, where there is limited space and many connections are required.

Another key advantage of QFP packages is that they can dissipate heat better than older designs such as dual in-line packages (DIP). The larger surface area provided by QFPs allows them to release heat easily, hence preventing the electronic components from overheating.

Designing QFP packages is convenient and very adaptable. Additionally, they connect well with several circuits like microcontrollers, digital signal processors (DSPs), and programmable logic devices.

QFPs are designed to be mounted on the surface of circuit boards. Therefore, their attachment to circuit boards is made easy. For this reason, they are fitting to assembly lines with less cost on manual labor.

The important aspect of QFP packaging is its thinness and low-profile design; however, customers always prefer smaller, lighter, and portable products. However tiny in size, QFP electronics function effectively within them all.

Even though Quad Flat Packages (QFP) are conducive to automation, their structure could make manufacturing complicated. During soldering, there might be issues like bridging or wrong connections due to the close arrangement of pins. Also, special equipment for these packages will increase production costs.

When it comes to prototyping, QFP packages prove to be more difficult compared to DIP (Dual In-line Package) packages. This is because QFPs have their pins placed so closely together that precision placement and soldering must be done.

While QFPs can serve many purposes, they are not always the best option. For instance, if a design needs high thermal conductivity or requires a particular mounting method, it is better to use other packaging options, such as ball grid arrays (BGAs). The right package should suit the application requirements.

QFP packages may accommodate quite a number of pins, but in cases where the pin count becomes very high, the size of the package increases proportionately, leading to large bulkier designs, which may counteract the miniaturization goal for circuits, making them difficult to fit into compact designs using QFPs.

A Quad Flat Package (QFP) refers to a category of surface mount technology (SMT) used in electronic devices. Its body has a square or rectangular shape from which metal leads emerge from all four sides.

The leads come with either a gull-wing shape (curved away) or a “J” shape (curved inwards), which facilitates soldering on circuit boards and inspecting connections.

QFP packages are often preferred due to their excellent thermal and electrical properties. Larger sizes allow for better heat dissipation and, hence, more possibilities for interconnections.

One of the major benefits of QFP packages is that they incorporate many leads. Therefore, handling more input/output pins is much easier when developing advanced circuits.

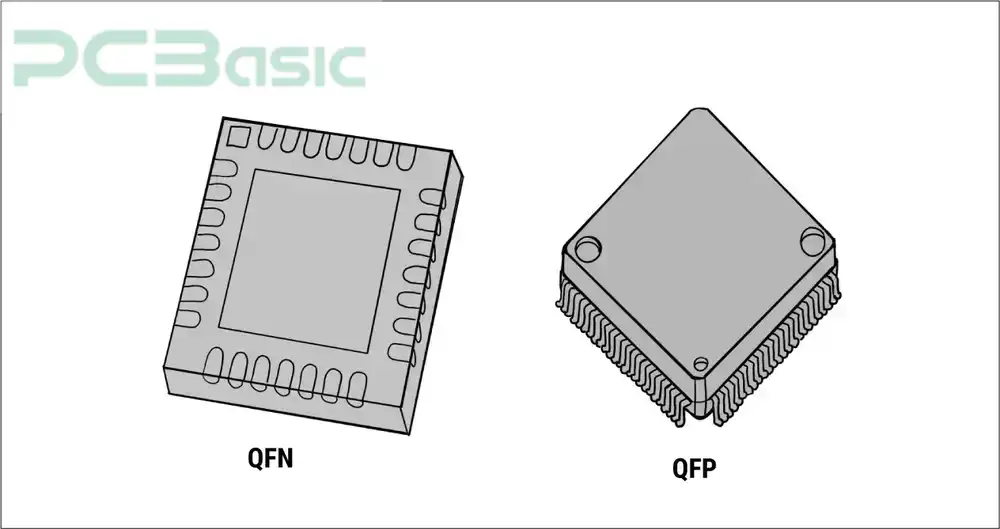

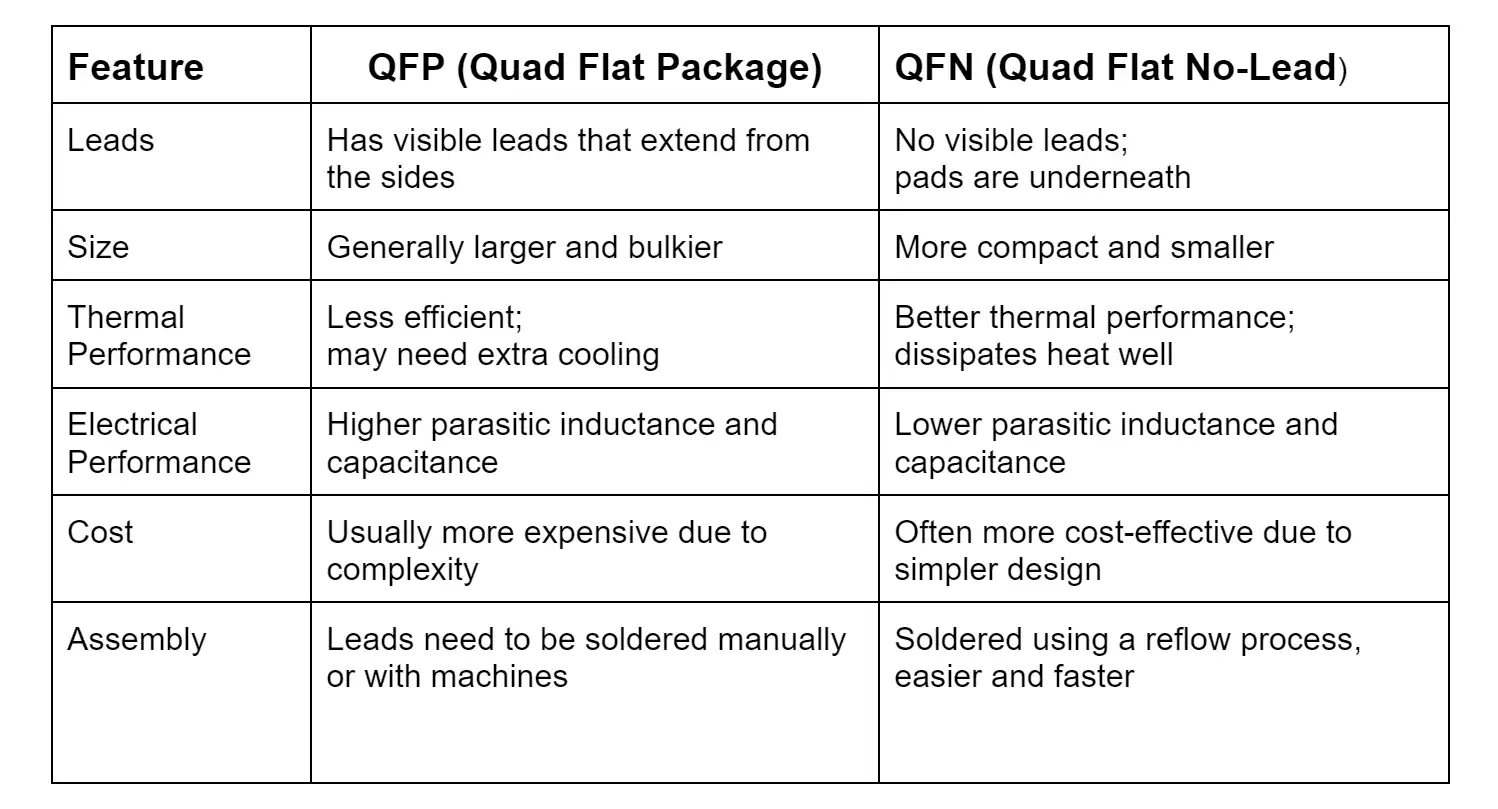

In general, compared to QFN, package types are relatively low-priced. This is because they have been manufactured for quite some time hence cheaper due to mass production as well as widespread availability.

QFN package, which is also called MLF ( Micro Lead Frame) or SON ( Small Outline, No Lead ), is built in a flat square or rectangular shape with no visible leads on the outside.

These connections are made up using pads on the bottom of the QFN package that are linked directly to the PCB pads when the component is connected.

Saving Space: These packages are small and compact, making them perfect for use in many industries.

Better Performance: It gives better heat and electrical flow and also reduces unwanted electronic issues.

Cost-Effective: QFN packages are cheaper than QFP packages because of their smaller size, easy use, and simple design.

QFP (Quad Flat Package) has been the most influential in the electronic industry due to its flexibility, small size, and high reliability. Perfect for both consumer electronics and industry, it can take a high amount of pins and, therefore, can get rid of the heat. As technology continues to improve, the QFP system exhibits higher operating efficiency and performance, leading to enhanced power of QFP. The analysis of the QFP package also indicates that its design and functionality need further development in the future, although the demand for this electrical component will rise. However, its main characteristics, such as pin density and maximum performance, will remain paramount and guarantee the package's leadership in the future.

Assembly Enquiry

Instant Quote