Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Process: ENIG-Electroless Nickel Immersion Gold

Designing on the PCB relies mostly on the type of surface finish you choose. It is one of the most important steps since it can make or break your project. It impacts the final product's performance, quality, and longevity, and you should choose it correctly.

Now, you might be wondering which surface finish I should use in such a case. Then, fret not, as we're here to help you out.

Among the top choices in the industry, ENIG (Electroless Nickel Immersion Gold) stands out as a premier solution. Why? Because it provides the flatness your projects are looking for! And this is why we at our PCB manufacturing facility employ the best ENIG processes to ensure superior conductivity, corrosion resistance, and a flat surface ideal for soldering.

Well, as the “GOLD” remains in its name, let’s find out why ENIG finish stands tall in the industry.

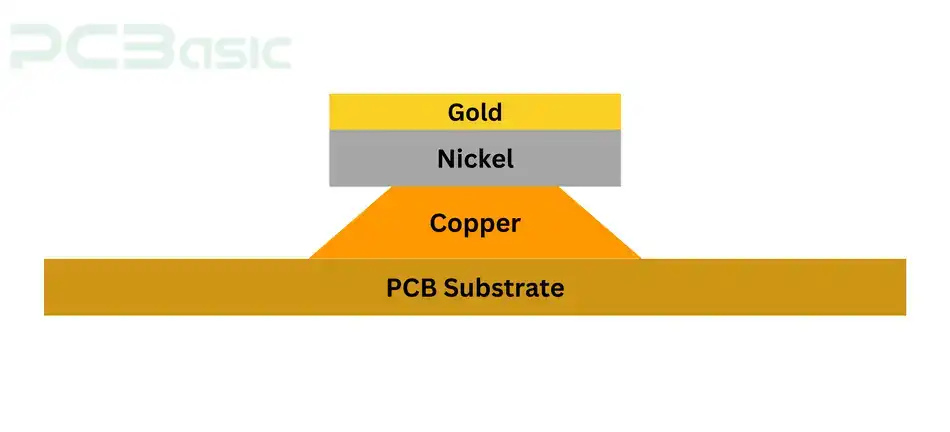

As discussed earlier, ENIG plating is a widely used surface finish in PCB manufacturing. It is mostly made up of two layers:

1. Nickel Layer: It provides a barrier and structural support

2. Immersion Gold Layer: It protects the nickel from erosion and offers excellent solderability.

Now you must be wondering how ENIG finish is applied to the PCB. So, the process begins with the electroless deposition of nickel onto the copper traces that forms a robust and corrosion-resistant base for your projects. Then, in the next step, the immersion gold layer is chemically deposited onto the nickel, ensuring your design has a uniform and precise coating.

Also, ENIG PCB provides superior performance in solder joint reliability and a long shelf-life which has become our go-to finish for advanced PCBs.

ENIG finish mostly consists of two primary layers, each having a great impact on your design’s overall performance and reliability. Let’s have a broader picture of it.

The first layer you'd commonly see is the electroless nickel layer. It acts as a barrier between the copper pads and the gold finish and will also help you in making the main structure for your soldering. If we talk about its thickness, you'll usually find it ranging from 3 to 6 microns. It gives the following benefits to your PCB.

● Excellent protection against oxidation and corrosion.

● It offers a reliable base for solder joints, enhancing mechanical strength.

● It helps resist physical wear, which is critical for connectors and other high-contact areas.

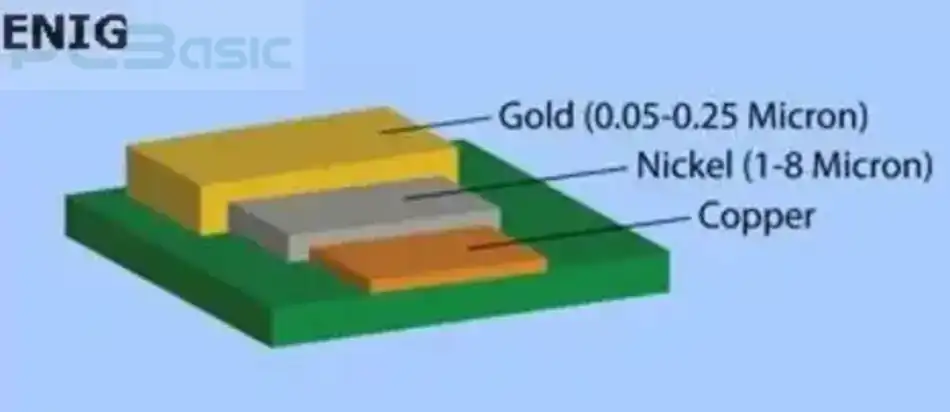

It is a thin gold layer that is chemically deposited over the nickel to give it extra protection from oxidation and make sure that your PCB has excellent solderability. In comparison to the electroless nickel layer, it is much thinner ranging between 0.10 to 0.50 microns.

This layer offers exceptional wettability, allowing you to easily solder the components. Even your fine-pitch designs too! Also, it keeps the nickel from tarnishing, which is crucial for long-term performance.

If you're wondering if it's thin, how come it comes as a gold standard? Then, as we all know, "gold" itself is a metal which is a good conductor. So, despite its thinness, the gold layer provides excellent conductivity, making it ideal for critical contact points like connectors and pads.

Both these layers work side by side, providing your PCB with a smooth and flat surface for precise soldering. Additionally, we also use nickel gold plating in all our PCBs to provide high-tech applications.

In the ENIG process, precise control over the thickness of both the nickel and gold layers is critical to ensuring optimal performance, reliability, and manufacturability of PCBs. So, let's take a look at each component's thickness.

The nickel layer typically ranges between 3 to 6 microns or 120 to 240 microinches. But what if your nickel layer is below 3 microns? It might lead to insufficient barrier properties, causing intermetallic formation between the copper and solder, which compromises the joint’s strength.

Similarly, a nickel layer thicker than 6 microns can result in increased brittleness of the solder joints, particularly in fine-pitch components, where flexibility is crucial.

The gold layer is comparatively thinner than nickel one ranging between 0.5 to 0.10 microns or 2 to 4 microinches. This layer ensures good electrical conductivity, but if your gold layer thickness is below 0.5, then it might cause corrosion of underlying nickel. It also leads to poor solderability and reduced shelf life of the PCB.

Our manufacturing process ensures that both the nickel and gold layers are deposited with extreme precision. Using advanced chemical control systems and regular thickness monitoring, we consistently achieve optimal thickness profiles, ensuring high-performance and reliable PCBs for various applications.

The ENIG process is a widely-used surface finish in the PCB world. It provides both excellent solderability and strong corrosion resistance. The ENIG plating usually involves the following six steps. Here’s a complete breakdown of the ENIG process.

The first step before applying the surface finish is to get some pre-treatment done. Our team first cleans the PCB from contaminants, oxides, or residual chemicals. This step is critical as it ensures proper adhesion of the nickel gold plating. Then we apply a microtech solution to slightly roughen the copper surface as it greatly improves the surface's adhesion properties. As we move forward, the copper surface is activated using a catalytic solution, which makes the copper chemically receptive to the nickel deposition.

In the next step, the PCB is immersed in a nickel plating bath containing:

1. Nickel

2. Salts

3. Sodium hypophosphite (the reducing agent)

4. Stabilizers

Typically you'll encounter nickel plates containing 7-10% phosphorus, which enhances its corrosion resistance and improves its durability, especially for multi-reflow cycles. At this stage, we would recommend you uniformly apply your nickel deposition as it forms the foundation for both the soldering process and the final product's mechanical strength.

After the nickel layer is deposited, the ENIG PCB is immersed in a gold solution where a chemical displacement reaction occurs. The best part about this step is that gold displaces the top nickel atoms without requiring electricity. Well, we would like to give a short tip here: you should control the gold thickness here as it is essential to avoid issues like gold embrittlement, which could weaken solder joints if the thickness is more than the recommended standard (0.5-0.10 microns).

Once done with the nickel and gold deposition, it's time to move on to the next steps. First, you would rinse the PCB in deionized water since it does wonders for removing any residual chemicals left from the previous steps.

Then our team carefully dry out the boards using either air or heat dryers whenever needed to ensure no moisture is present in the ENIG PCB final outcome. Thorough rinsing and drying prevent chemical contamination and ensure that the finish remains intact and free from defects.

After rinsing and drying, it's time to do some final inspections and testing to see if the product is ready to go. To check the thickness of both nickel and gold layers, you must use X-ray fluorescence (XRF) and other non-destructive testing methods to ensure that your final design is of standard specifications.

Moreover, you also need to inspect the test pads and make sure no single component is left behind. Then as you might be thinking the surface is checked for visible defects such as discolouration, pitting, or uneven plating. At this point, we suggest you should give your best and must not be in a hurry since consistent testing ensures that the ENIG process is successfully executed.

Lastly, the final quality checks are done. Sometimes, you’d go above and beyond for additional functional testing to simulate real-world uses, verifying that the ENIG finish performs well under various conditions. Additionally, we would recommend you make a final quality report documenting the measurements, inspection results, and any testing performed. This way, your customers would know under what circumstances the PCB would work great and if they meet the industry standards.

Since ENIG is the gold standard in the world of surface finishes, it has limitless advantages. Some of its major advantages are discussed below.

ENIG plating provides a highly flat and smooth surface for PCB design, which ensures uniform soldering across all pads and components. This thing is extremely important for fine-pitch components and smaller parts where other finishes don't reach easily. The thing where it stands tall is its reliability in solder joints, which reduces the risk of cold solder joints or poor connections, which can be critical for high-performance and high-reliability applications.

It provides two-step corrosion resistance. First, the gold layer protects the underlying nickel from oxidation and tarnishing. And then, the nickel layer, combined with the gold topcoat, provides excellent resistance to environmental degradation, making ENIG ideal for real-world examples, including automotive and industrial applications.

ENIG is compatible with lead-free soldering processes, making it a suitable choice for PCBs that need to meet environmental regulations like RoHS (Restriction of Hazardous Substances). The gold layer withstands the high temperatures of lead-free solder reflow without degradation. Moreover, the ENIG finish can withstand multiple reflow cycles, which is important for boards that undergo various soldering processes during assembly.

Unlike silver-based finishes, ENIG does not suffer from silver migration issues, where silver can migrate into solder joints and cause reliability problems. This makes ENIG a more stable choice for high-reliability applications.

While ENIG (Electroless Nickel Immersion Gold) is highly regarded for its numerous benefits, it does have some shortcomings that may impact its suitability for certain applications. Here are the primary limitations:

● The use of gold makes ENIG expensive.

● If the gold layer is too thick, it might result in gold embrittlement.

● For applications requiring high-power handling, ENIG may not always be the choice compared to other finishes like ENEPIG or HASL.

Due to its unique properties, ENIG PCB is a versatile surface finish used in various high-performance and demanding applications. To make it simpler for you, we have computed a table for ENIG applications.

|

Industry |

Examples |

Why is it the Best? |

|

Consumer electronics |

Smartphones, tablets, and wearable devices. |

ENIG’s excellent solderability and flat surface make it ideal for complex interconnects found in smartphones. |

|

Automotive |

Engine Control Units (ECUs), Advanced Driver Assistance Systems (ADAS). |

The surface finish’s corrosion resistance and durability are critical for automotive ECUs to perform perfectly well in high vibrations. |

|

Medical Devices |

Diagnostic equipment and implantable devices. |

As we all know, medical devices and equipment require precise and clean solder joints. In this, ENIG surfaces play an integral role in providing accurate performance. |

|

Industrial Equipment |

Control systems and automation. |

Nowadays, ENIG is widely used in automated systems where high reliability and durability are essential, including robotics and process control equipment. |

|

High speed and High-Frequency Applications |

RF and Microwave circuits and Data acquisition systems. |

ENIG ensures that the electronic connections are stable and reliable for systems that handle high-speed data transfers. |

When comparing ENIG with other PCB surface finishes, it’s essential to consider each's specific characteristics, advantages, and limitations. Here’s a detailed comparison of ENIG versus ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) and ENIG versus HASL (Hot Air Solder Leveling).

Let’s have a table for this one too.

|

ENIG |

ENEPIG |

|

|

Process and Composition |

ENIG is usually made of nickel and gold. Its process is simple: Nickel is deposited via electroless plating, followed by immersion in a gold bath. |

ENEPIG is made of nickel, palladium, and gold. Similar to ENIG, nickel is electroless deposited, followed by a palladium layer and then finished with immersion gold. |

|

Applications |

Suitable for high-reliability applications where additional durability and long-term performance are critical, such as medical devices. |

Suitable for high-performance applications, including consumer electronics and telecommunications. |

|

Advantages |

It provides excellent solderability and flatness, making it suitable for fine-pitch components. |

Palladium adds extra protection and provides better long-term performance and solderability, especially for high-reliability applications. |

|

Cost |

cheaper |

It is expensive due to the additional palladium layer |

When ENIG is compared to HASL, the performance, precision, and application differences become clear. ENIG provides a smoother, flatter surface finish, critical for high-density and fine-pitch components commonly found in advanced electronics.

ENIG's flatness ensures your projects are sleek, offering precise soldering. And the risk of solder bridging? They are slim to none. Additionally, it offers excellent corrosion resistance due to the protective gold layer, which shields the underlying nickel from oxidation. This ensures long-term reliability and solderability, especially for high-performance projects such as those used in telecommunications and aerospace.

Comparatively, HASL is more cost-effective. At some point, it might leave you with uneven surfaces, which can cause assembly challenges, particularly for fine-pitch components. Additionally, HASL uses molten solder for assembly, and chances are you might drop excess solder, which increases the risk of defects like solder bridging.

While HASL is a simpler and cheaper process, it lacks the precision, flatness, and durability ENIG provides, making ENIG the preferred option for high-reliability and high-performance PCBs.

ENIG is one of the best surface finishes you would get in the industry. Not only does it provide precision and reliability, but it is also cheaper compared to its competitors. Starting from its working process, unparalleled flatness, good solderability, and whatnot, ENIG is a go-to choice for designers in the PCB industry. Moreover, if we compare it with its competitors like HASL and ENEPIG, ENIG will still remain at the top because of its quality and long-term durability. So, which surface finish do you find the best? Is it ENIG or HASL?

Assembly Enquiry

Instant Quote