Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > How the Flying Probe Tester Enhances PCBA Testing Efficiency?

No matter what type of manufacturing industry it is, both manufacturers and consumers have always required the quality and reliability of their products. Hence, the phased testing part of the production process is an essential approach to the quality of the output. One of the testing methods to ensure electronic devices operate as designed is assembled printed circuit board (PCB) testing. Flying probe testing is one of the flight test methods available and is among the least expensive and fastest methods of testing for small to medium-sized PCBs and prototypes. As a flexible alternative to ICT testing, flying probe testing offers fixtureless inspection that is ideal for fast and accurate validation. In many cases, flying probe vs ICT shows clear advantages in terms of cost and speed for prototype runs.

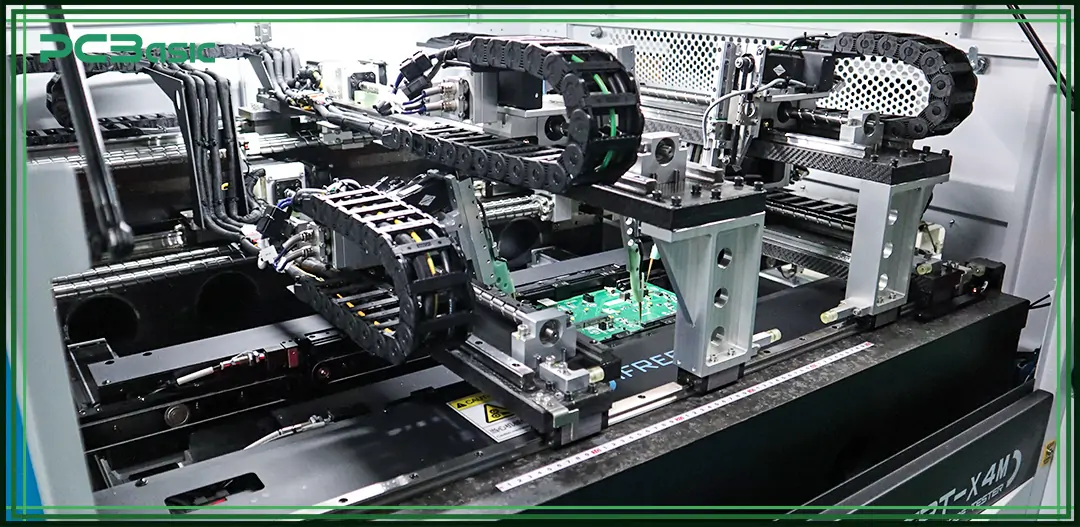

In order to improve the quality and efficiency of circuit board assembly and inspection, PCBasic recently introduced a flying probe tester, which significantly improves the speed and accuracy of product inspection. This advanced flying probe machine enables high-precision PCB flying probe testing, covering multiple test points without requiring custom fixtures. The use of flying probe testing not only enhances detection capability but also shortens turnaround time in contrast to traditional ICT testing methods.

In this blog post, let's explore what flying probe testing is, its advantages, and how flying probe testing can improve the efficiency of PCB flying probe testing in PCB assembly processes.

Before understanding the advantages of flying probe testing, let's first address a basic question: What is flying probe testing? Flying probe testing is an efficient way to detect electrical faults on circuit boards. The flying probe tester moves through multiple probes on the printed circuit board to test various points on the PCB assembly and detect whether the board has electrical faults like open circuits, shorts, or connection errors.

Since the flying probe tester directly contacts the test points with its probes, it does not require fixed fixtures like those used in ICT testing, offering high flexibility and fast testing speed. This makes flying probe testing highly advantageous in the debate of flying probe vs ICT, especially for small-batch or prototype runs. As a result, flying probe testing has become increasingly popular in PCB flying probe testing for PCBA inspection. More and more manufacturers are investing in advanced flying probe machines to enhance test accuracy and speed in modern PCB assembly lines.

As for testing, the flying probe tester has excellent advantages compared with other testing methods, and it is an important link in the PCBA test process because of its high flexibility and accuracy, fast detection speed, and high-cost effectiveness.

Perhaps the most significant benefit of flying probe testing is its great degree of flexibility and efficiency. Traditional ICT testing requires the production of specialized ICT fixtures for different circuit boards, which costs time and money.

In contrast, the flying probe machine does not require a custom fixture; only multiple flying probes are directly in contact with the circuit boards for detection, which can quickly adapt to different circuit boards. As a result, flying probe testing is cost-effective, making it an ideal solution for small-batch production, rapid adjustment, and testing of different board dimensions.

Compared to other testing methods, the speed of the flying probe testing is also particularly outstanding. It can test various test points on the assembled PCB in a shorter time. Using multiple flying probes, the flying probe tester can test for electrical faults on multiple printed circuit boards at the same time, greatly reducing inspection time.

Moreover, the flying probe testing also significantly increases the accuracy of the circuit board testing. Flying probes are capable of testing the test points, with a significantly reduced risk of human error ensuring reliable results and measurement.

As we mentioned before, flying probe testing does not require a customed test fixture. When dealing with small batches, prototypes or rapid designs, a flying probe tester is a superior choice and is very cost-effective for low to medium batch production.

The flying probe tester conducts electrical testing at the PCB assembly testing stage without any fixtures, detecting possible defects and issues in a short time cycle. It works seamlessly with other standard processes for PCB production, like soldering and assembly, without adjustment or disruption to the process flow. This allows for tighter integration of production efficiencies and assurance of product quality consistency.

By the way, the flying probe tester has a high degree of adaptability. The flying probe tester is highly flexible. With the program and the flying probe, it is able to test different complicated circuit board. Testing is fast and precise, even for densely populated PCBs with irregular layouts.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

ICT testing (In-Circuit Testing) is a commonly used traditional method in PCBA testing. It requires a dedicated test fixture that checks soldering and component issues by simultaneously contacting a large number of test points on the PCB. Although ICT has a fast detection speed and is suitable for mass production, the production cost of fixtures is high and the lead time is long, making it inefficient for small-batch or frequently design-changing projects. This is also the key point that flying probe vs ICT is often discussed.

Let’s compare the two testing methods in a chart:

|

Feature |

Flying Probe Testing |

ICT Testing |

|

Test Fixture |

No fixture required |

Requires a custom fixture |

|

Setup Time |

Very low |

High |

|

Cost (NRE) |

Minimal to none |

High for small batches |

|

Test Speed |

Slower than ICT for large volumes |

Faster for high-volume testing |

|

Flexibility |

High – easily reprogrammed for design changes |

Low – limited by physical fixture constraints |

|

Application |

Prototype, low-mid volume, complex boards |

High-volume, mature designs |

At PCBasic, we combine over 15 years of PCB design experience and project management experience with the advanced quality inspection method - flying probe testing. On the premise of ensuring reliability, we significantly improve the production efficiency of PCBA. Our flying probe tester does not require the production of custom test fixtures. It is highly suitable for rapid prototyping and flexible small-batch production (completed in the Shenzhen factory), as well as large-batch orders (delivered by the Huizhou factory).

Compared with ICT testing, flying probe testing saves the time and cost of fixture production, has a faster delivery speed and stronger adaptability, thus it is particularly suitable for the rapidly changing electronic manufacturing demands of today. We have a complete self-operated SMT stencil and fixture factory as well as CNC precision parts processing capabilities and can deliver stencils within one hour at the fastest.

And by the way, to ensure the stability of material supply and the guarantee of original products, we have equipped an intelligent electronic material central warehouse. Meanwhile, through the one-click import of BOM and the real-time quotation system, the procurement and production processes have been greatly simplified.

As a national high-tech enterprise, PCBasic has passed ISO13485, IATF 16949, ISO9001, ISO14001, and UL certifications. It is also a member unit of IPC and has obtained more than 20 patents related to quality inspection and production management.

Partner with PCBasic for faster, more reliable, and worry-free PCBA production.

The flying probe tester is a variable tool in the field of PCBA testing. Its cost-effectiveness, flexibility, and accuracy greatly surpass traditional PCBA testing and greatly improve the testing efficiency.

Through the introduction of a flying probe tester, PCBasic greatly improves production efficiency and product quality and constantly meets the needs of customers. Whether in high-volume production or customized small-batch production, PCBasic can provide you with the most reliable and efficient PCBA testing services to help your electronic products to market quickly and successfully pass quality inspection.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.