Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Electronics Assembly: The Core of EMS Manufacturing

With the rapid development of electronic technology today, electronics manufacturing plays a vital role in putting electronic products into practice. From smartphones to aerospace and medical device, the design and assembly of electronic device is at the heart of technological innovation. With the increasing reliance of various industries on complex electronic technologies, the demand for skilled electronics assemblers, professional EMS company, and capable electronics assembly companies has never been greater.

In any electronic device, every electronics assembly or electronic component assembly must be precise, efficient and of high quality. Whether handled by an experienced EMS supplier or an in-house electronics manufacturer, this process forms the core of modern EMS manufacturing workflows.

In this blog, let’s explore the importance of electronics assembly in the production of electronic devices, learn the key processes, types of assembly, and why PCBasic is your reliable electronics assembly company providing high-quality electronics manufacturing services and full-spectrum electronics manufacturing service support.

The meaning of EMS has far exceeded the category of traditional contract manufacturing and assembly. EMS, namely electronics manufacturing services, is an integrated service model. Professional EMS companies provide services ranging from the conceptual design and prototype development of electronic products to electronics assembly and functional testing. From then on, to one-stop services for finished product assembly and global logistics distribution.

Simply speaking, EMS manufacturing is not just manufacturing circuit boards, but helping customers turn an idea into a complete electronic product that is truly marketable. An experienced electronics assembler is not only responsible for soldering components, but also provides professional support in multiple aspects such as material selection, process optimization, cost control, quality improvement and delivery date management, thereby helping customers reduce production costs, improve product performance and reliability, and significantly shorten the cycle from product design to market launch.

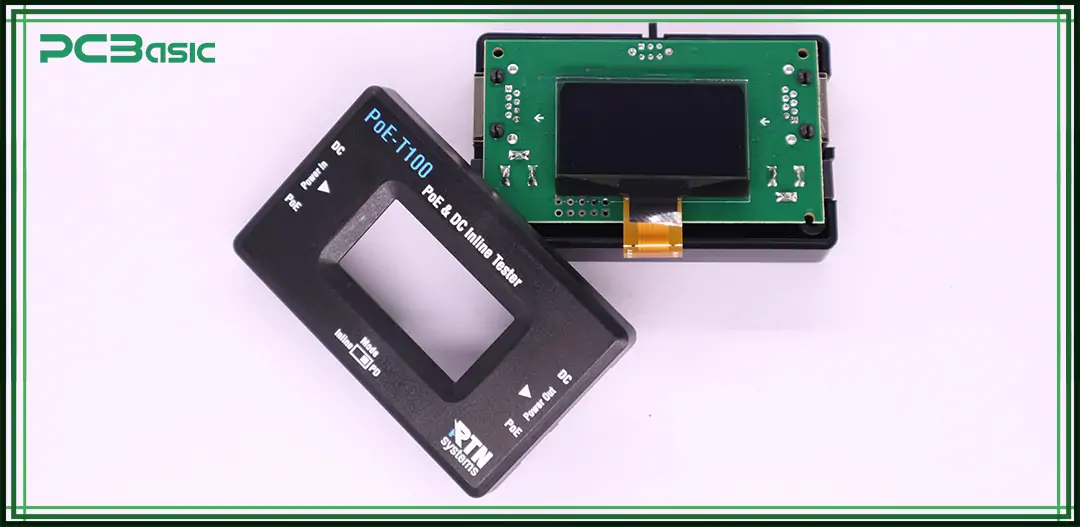

Electronics assembly refers to the process of accurately assembling and soldering various electronic components, such as chips, resistors, capacitors, connectors, onto the printed circuit board (PCB). This step is the core part in manufacturing any electronic product, which is directly related to whether the product can operate normally and is the foundation of the entire EMS manufacturing process.

Modern electronics assembly services have been highly automated and equipped with advanced devices such as surface mount technology (SMT) machines, reflow ovens, and automatic optical inspection (AOI) instruments, enabling high-precision and high-efficiency mass production. Meanwhile, these services are also an indispensable part of every complete electronics manufacturing service, directly determining the final quality, stability and market competitiveness of electronic products.

Connecting the electronic components to printed circuit boards (PCBs) is the key step that electronics assembly technologies help with. Due to the continuous expansion of the application field of electronic products, there are various assembly methods. The assembly technology used depends on the product and application needs. The three common electronics assembly technologies include through-hole assembly, surface mount technology and hybrid assembly.

Through-Hole Technology (THT): The old method of assembly is through-hole technology where inserting electronic components through holes on the PCB. It is high mechanical strength and electrical connection reliability. But the assembly technology is more complicated, and it has a larger footprint.

Surface Mount Technology (SMT): SMT is a very common application for assembling electronic products. Surface Mount Technology means putting components directly on the surface of the PCB. Ideal for mass production, it enables designs to be more compact, circuit density to be higher, and production speeds to be faster.

Mixed Assembly: This hybrid assembly combines through-hole technology and surface mount technology. Hybrid assembly is ideal for products that can benefit from both techniques. This is popularly used in fast electronic devices.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

In order to ensure the performance, reliability and quality of the final product, the entire electronic component assembly process needs to follow a systematic step, from the initial PCB design to the final product packaging, each stage is crucial. This not only involves the precise implementation of the technology, but also requires high-quality material support and rigorous quality control measures.

1. PCB Design and Prototype:

In this step, we design printed circuit boards, which are the backbone of the electronic device. Prototypes are manufactured and tested to ensure that they work as designed prior to mass production.

2. Component Sourcing:

After the PCB design is completed, the electronic components will be procured. Ultimately, working with reputable suppliers ensures that quality materials are present in the final assembly.

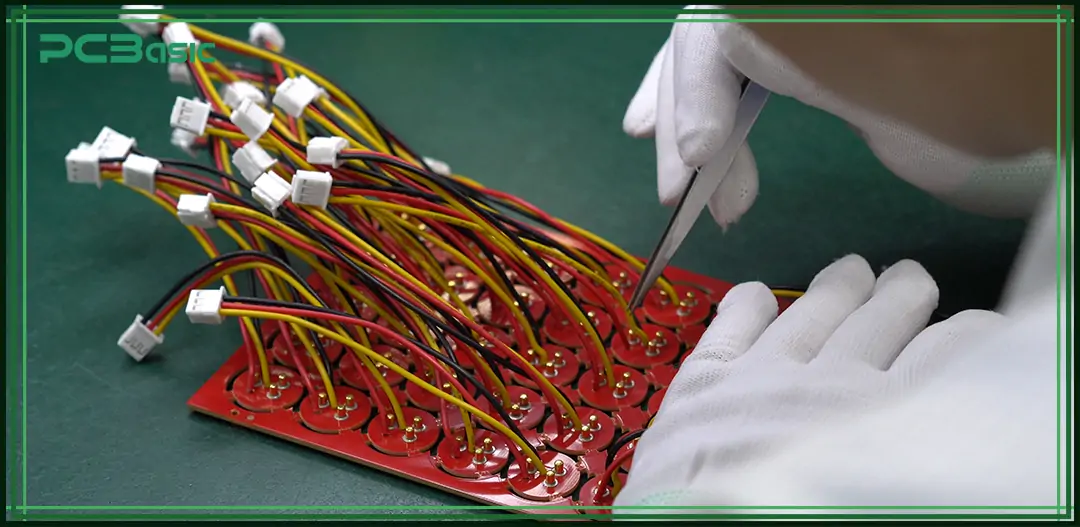

3. Soldering:

The next step is to solder electronic components on the PCBs. There are primarily two types of soldering processes: wave soldering for through-hole components and reflow soldering for surface-mount components.

4. Inspection and Testing:

Once the assembly process is completed, the electronic products are subjected to stringent inspection and testing, which involves checking if each component is placed in the correct position, soldered and functional properly. Typical inspection methods are AOI (Automated Optical Inspection) and X-ray.

5. Final Assembly and Packaging:

After the testing period, the electronic devices will be packaged into its final form, such as the housing, buttons and screens. That product will be boxed up and prepared for shipping.

Electronics assembly is an important part of making electronic devices. Without this crucial step, even the most innovative designs will remain at the conceptual stage. This ensures proper assembly so that electronic components such as resistors, capacitors, and microchips can be accurately placed and connected to facilitate interworking in the final electronic devices.

Select an electronics assembly company with years of experience, and you will enjoy their knowledge and professionalism in correcting this intricate assembly process. They guarantee that your electronic component assembly comes to completion with accuracy, dependability, and endurance. Moreover, electronics assemblers have experts who can identify potential problems in the assembly process early on, saving time and costs.

In the field of electronics assembly, choosing the right electronics assembly manufacturer is critical to the quality, performance and time to market of the final product. So, why choose PCBasic? I think the following reasons can convince you.

1. Experience and Expertise:

With over 15 years of experience in the electronics manufacturing industry, PCBasic brings unrivalled expertise in electronic component assembly and PCBA technology.

2. Advanced Technology:

PCBasic integrates an intelligent production management system and automated testing technology to ensure the accuracy of each product.

3. Quality Certification:

PCBasic has passed ISO9001, IATF16949 and ISO13485 certifications to ensure that all products meet international quality standards.

4. Fast and Reliable Service:

Whether you need small batch prototypes or large-scale production, PCBasic is able to meet your needs quickly and efficiently.

5. Extensive Industry Experience:

PCBasic serves a wide range of industries, from automotive and medical devices to consumer electronics and aerospace, providing unique solutions.

Electronics assembly is critical and simple. This is an important process to keep the electronic devices running properly as per high expectations of customers. From electronic component assembly and advanced PCB design, a proper electronic assembly company like PCBasic can do all of these tasks for you to easily produce electronic products in an accurate and efficient way.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.