Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Comprehensive Guide to Double-Sided PCB Assembly

In today's fast-evolving electronics industry, double-sided PCB assembly has become an essential solution for complex and space-efficient circuit designs. As electronic devices become more compact and advanced, the demand for double-sided PCB assembly continues to rise. At PCBasic, we are proud to be a leading double-sided PCB assembly manufacturer in China, offering top-tier solutions for high-quality PCB SMT assembly double-sided projects. With our in-house manufacturing capabilities and extensive industry experience, we are well-equipped to meet the needs of businesses worldwide.

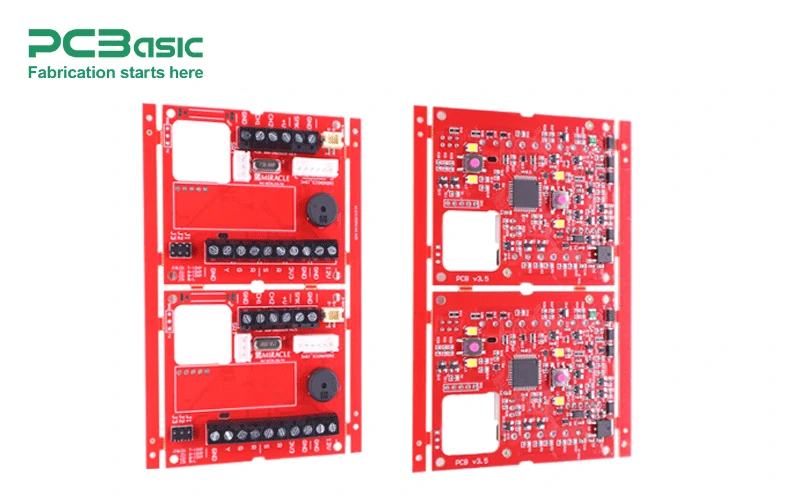

Double-sided PCB assembly involves the placement of components on both sides of a printed circuit board (PCB). This technique allows for increased component density, enabling more complex designs in a smaller space. Unlike single-sided PCBs, where components are mounted on one side, double-sided PCB assembly uses both sides of the board, which results in greater flexibility for designers and engineers.

A key aspect of double-sided mixed PCB assembly services is the combination of both surface-mount and through-hole components. This assembly type is crucial in electronic devices that require advanced functionality but are limited by space constraints. With the rise of miniaturization, double-sided PCB assembly is becoming more common in industries ranging from consumer electronics to telecommunications.

There are numerous benefits of using double-sided PCB assembly in your electronic projects. Some of the most significant advantages include:

· Increased Component Density: By using both sides of the PCB, designers can place more components in a limited space, which is particularly beneficial for compact and portable devices.

· Improved Circuit Performance: The increased density can improve signal integrity and reduce noise, resulting in better overall performance for your products.

· Space-saving for Compact Designs: Double-sided PCB assembly allows for more efficient use of space, which is crucial for creating smaller devices without compromising on performance.

· Cost-effective for High-Performance Products: With double-sided PCB assembly, the need for additional layers is reduced, which can make production more cost-effective, especially in high-volume manufacturing. It is an ideal solution for high-performance electronics that require compact designs.

When selecting a PCB SMT assembly double-sided supplier, it's important to partner with a manufacturer that has both the technical expertise and the resources to deliver top-quality products. Working with an experienced China PCB SMT assembly double-sided manufacturer ensures several benefits, including:

· Competitive Pricing: As one of the leading PCB SMT assembly double-sided factories in China, we offer competitive pricing for high-quality products, making it easier for businesses to manage their budgets while receiving reliable assembly services.

· Quick Turnaround: We understand the importance of time in the electronics industry. By choosing a trusted supplier, you can expect fast, efficient service and timely delivery, even for complex projects.

· High-Quality Standards: Our factory adheres to international standards and certifications, ensuring that every double-sided PCB assembly meets strict quality control protocols. This guarantees a high level of reliability and durability for all assembled products.

At PCBasic, we provide comprehensive OEM double-sided PCB assembly services tailored to meet the unique needs of our clients. Here’s an overview of what we offer:

· SMT Assembly for Both Sides of the PCB: Our assembly process utilizes advanced SMT technology to place components on both sides of the PCB, optimizing space and performance.

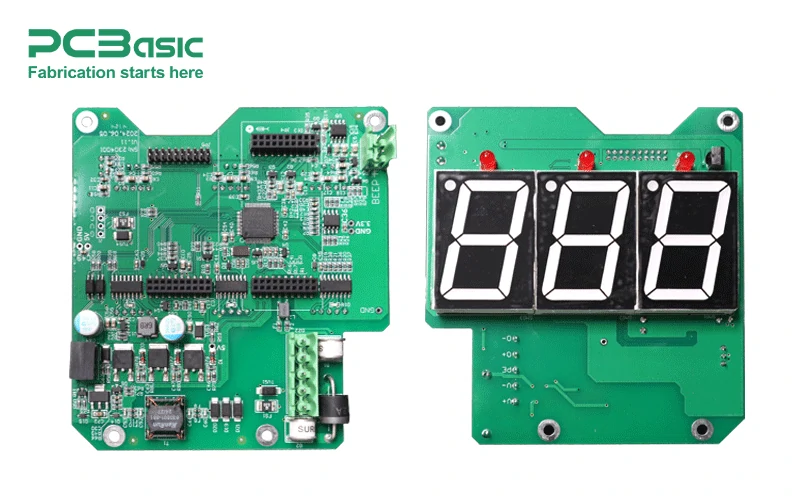

· Testing and Inspection: We employ rigorous testing and inspection processes to ensure that every double-sided PCB assembly meets the highest standards of quality. This includes automated optical inspection (AOI), functional testing, flying probe testing and reliability testing.

· Compliance with International Standards: Our manufacturing processes comply with global industry standards, including IPC-610 and ISO certifications, ensuring that all products are up to par with the latest industry regulations.

With years of experience in double-sided PCB assembly, we stand out in the highly competitive market as a reliable partner for high-quality PCB SMT assembly double-sided projects. Here’s why you should choose us as your PCB SMT assembly double-sided manufacturer:

· Proven Expertise: We specialize in both OEM double-sided PCB assembly and complex double-sided mixed PCB assembly services, ensuring that your project receives the right expertise for optimal results.

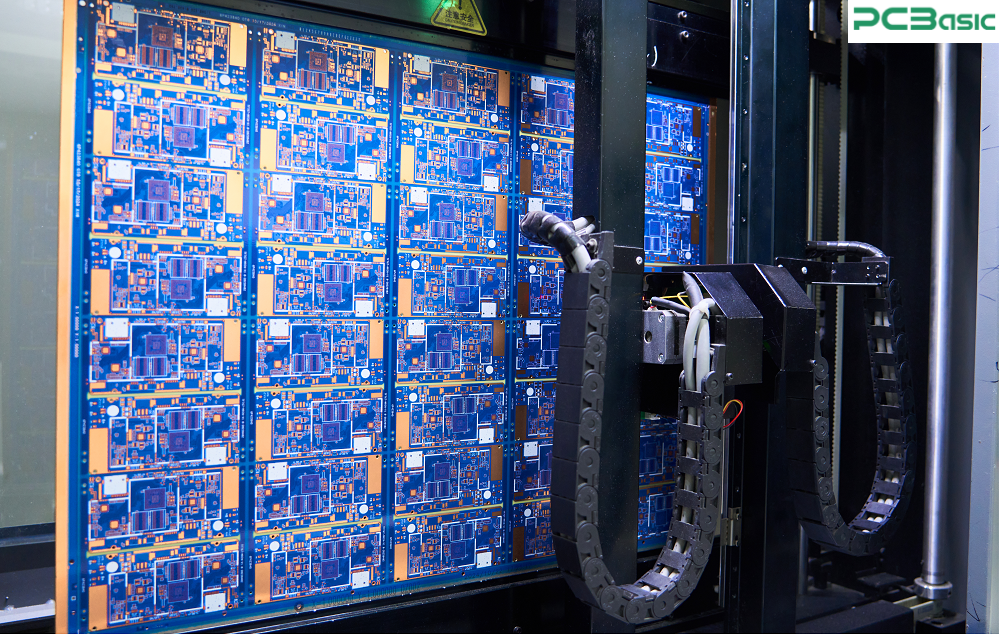

· Advanced Manufacturing Facilities: Our state-of-the-art factory is equipped with the latest PCB assembly technology, ensuring precise and efficient production processes for double-sided PCB assembly.

· Custom Solutions: Whether you're working on a low-volume prototype or large-scale production, we can tailor our PCB SMT assembly double-sided services to suit your needs.

· Comprehensive Support: From design and prototyping to mass production and testing, we offer end-to-end support for double-sided PCB assembly, ensuring a smooth and seamless production process.

Here is the article based on your outline with the requested keywords incorporated:

Double-sided PCB assembly involves a series of precise steps to ensure high-quality, functional circuit boards. Below is a breakdown of the PCB SMT assembly double-sided process:

The process starts with the PCB fabrication stage, where the bare PCB is created. This involves etching copper traces on both sides of the board, creating pads for component mounting, and drilling holes for through-hole components. The quality of PCB fabrication is critical as it lays the foundation for the entire assembly process.

Once the PCB is fabricated, the next step involves component placement on both sides of the PCB. For double-sided PCB assembly, components are carefully positioned on both the front and back of the board. This process uses SMT assembly technology to place components efficiently, including both surface-mount devices (SMDs) and through-hole components.

After component placement, the next crucial step is soldering. There are two main methods used in double-sided PCB assembly:

Reflow soldering: This method is primarily used for surface-mount components. The board is heated to melt solder paste, which bonds the components to the PCB.

Wave soldering: Used for through-hole components, this process involves passing the PCB over a wave of molten solder to create reliable connections.

After soldering, thorough inspection and quality control are carried out. This includes Automated Optical Inspection (AOI), X-ray inspection, and other techniques to verify the integrity of the solder joints and ensure that no components are misplaced or faulty. Ensuring a high-quality end product is crucial, and this step is essential to the double-sided PCB assembly process.

At PCBasic, we take quality seriously, and our quality assurance methods are designed to ensure that every double-sided PCB assembly meets the highest standards. Our key quality control methods include:

AOI (Automated Optical Inspection): We use AOI systems to inspect the placement and soldering of components. This technology helps identify defects such as misalignment or insufficient solder joints on both sides of the PCB, ensuring a high level of precision and reliability.

Functional Testing: In addition to visual inspection, we perform functional testing to verify that the double-sided PCB assembly works as intended. This involves checking the functionality of the assembled PCB in its operational environment to ensure it meets specifications.

Compliance with IPC Standards: All of our double-sided PCB assemblies are manufactured according to IPC standards, ensuring that the boards meet the international quality standards for electronics. These standards are critical for ensuring reliability and performance.

Reliability Testing for Different Industries: We also conduct reliability testing to ensure the double-sided PCB assembly can withstand environmental stresses, such as temperature extremes and vibrations, depending on the industry it is intended for. This is particularly important in industries like automotive, industrial equipment, and telecommunications.

Double-sided PCB assembly is widely used across various industries due to its ability to increase component density and optimize space. Some of the most common applications include:

· Consumer Electronics: From smartphones to wearable devices, double-sided PCB assemblies are crucial for consumer electronics where space-saving and high performance are critical.

· Automotive Electronics: In the automotive industry, double-sided PCB assembly is used in everything from infotainment systems to safety features, where reliability and compact designs are essential.

· Telecommunications: Telecommunication equipment often requires double-sided PCB assemblies due to the need for compact, high-performance circuit boards that can handle high-speed data transmission.

· Industrial Equipment: Industrial machines and control systems rely on double-sided PCB assemblies for their durable and space-efficient design, which is critical for handling complex electronic systems.

Getting started with double-sided PCB assembly is simple and straightforward at PCBasic. Here's how you can begin your project:

Upload Gerber Files: Begin by uploading your Gerber files and Bill of Materials (BOM) to our online platform. These files provide the design specifications needed to manufacture your double-sided PCB assembly.

Request a Quote: Once your files are uploaded, request a custom quote for your project. We’ll provide a detailed breakdown of the pricing and estimated production time.

Start Your Project: After receiving your quote, we’ll begin the assembly process. Whether you're looking for OEM double-sided PCB assembly or need complex double-sided mixed PCB assembly services, we’re here to provide a tailored solution that fits your needs.

Global Support: We offer comprehensive support for clients worldwide. Our streamlined process ensures that you receive your double-sided PCB assembly on time, whether you're located in the United States, Europe, or anywhere else.

Choosing PCBasic as your PCB SMT assembly double-sided supplier ensures that your double-sided PCB assembly is produced with the highest standards of quality, reliability, and performance. As one of the leading PCB SMT assembly double-sided manufacturers in China, we offer cost-effective, fast, and high-quality solutions for your projects. Whether you need OEM double-sided PCB assembly or specialized double-sided mixed PCB assembly services, our team of experts is here to support you every step of the way.

Contact us today to get a custom quote or learn more about how our PCB SMT assembly double-sided solutions can bring your designs to life!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.