Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Black PCB | The Ultimate Guide

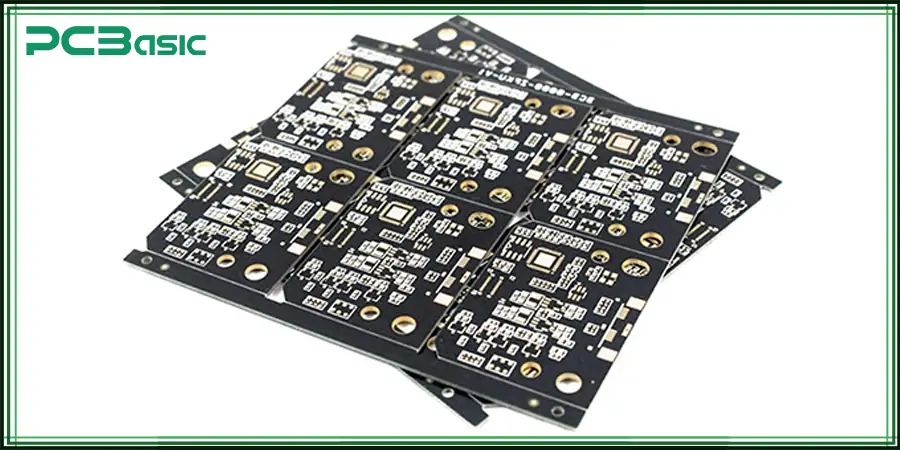

PCBs, or printed circuit boards, tie together electronic components. Found in top-of-the range electronics, solder mask-covered black PCBs offer a premium look. Black PCBs are also used in motherboards, high-end laptops, and in-game systems and are appreciated for their look and dependability. Black solder masks lower light reflection in optical and industrial uses.

Black PCBs are challenging to make and inspect as well because of color-inhibiting flaw identification, which results in extra strict quality inspections. Still, black PCBs are somewhat common in electronics.

1. Aesthetic Attraction – Black PCBs give electronic devices a high-end and sophisticated look, which is why they are used in high-end products.

2. Light Absorption – The black solder mask reduces the reflection of light, thus being useful in optical use and the use of LEDs.

3. Heat Dissipation – Some manufacturers attest that black PCBs can have better heat dissipation properties when combined with the right materials.

4. Branding & Customization – Companies employ Black PCBs to distinguish their products from others and build a customized identity.

● Challenging Inspection – Black PCBs make defects and marks more challenging to identify, and that raises the likelihood of concealed faults.

● Higher Manufacturing Cost – The black solder mask calls for accurate application, and hence a marginally higher manufacturing cost.

● Heat Storage Potential – Black PCBs, although helping to dissipate heat in some situations, will store heat if not well designed.

● Limited Availability – Not all manufacturers produce black PCBs, so it is more difficult to find the material.

Black PCBs are both good and bad and therefore, they would be well suited for certain projects but not necessarily well suited for every project. Whether or not to use a black PCB would be based on the needs of the electronic device and the ability of the manufacturing facility.

Black PCBs are highly employed in industries where design, functionality, and performance all have to be balanced. Black PCBs are the preferred choice in most industries as they appear to be thin and have some material properties.

Most premium consumer electronics employ black PCBs since they provide a rich look. Premium graphic cards, gaming devices, and premium smartphones usually employ them due to their look and branding. The dark color provides low light reflectance, and it can be used to improve performance in some display-related applications.

New vehicles employ electronic components for safety, navigation, and entertainment. Black PCBs are utilized in dashboard controls, ADAS, and light modules. The solder mask is heat-resistant and resistant to mechanical stress so that the boards can be utilized in automobiles.

Some medical devices need PCBs that not only need to be reliable but also need to be compliant with regulations with utmost care. Black PCBs are used in imaging technology, medical diagnostic devices, and wearable health devices, where reliability and accuracy are of utmost concern.

Black PCBs find application in automation and manufacturing systems, sensors, and control panels. Their trait of being a seamless fit within a number of different units puts them in contention for use on projects where the parameters of greatest importance are reliability and performance.

Electronic components must work well under the harsh environment of space and the military environment. Black printed circuit boards (PCBs) are applied to communication equipment, navigation equipment, and unmanned aerial vehicles (UAVs) due to their strong structure and superior signal integrity when exposed to harsh environments.

PCBs are available in different colors, which are functional and aesthetically important. Although the most widely utilized is green, others such as black, red, blue, and white are also utilized depending on requirement.

|

PCB Color |

Common Applications |

Pros |

Cons |

|

Black PCB |

High-tech electronics, computer game equipment, cars, aircraft |

Smooth finish, reduces reflection of light |

Stringent test, greater expense |

|

Green PCB |

Consumer goods, computers, household electronics |

Low-cost, simple inspection |

Daily glance |

|

Blue PCB |

Industrial and medical applications |

High visibility for assembly |

Less common, may be costly |

|

Red PCB |

Prototyping and custom circuits |

Unusual look, pleasing contrast |

Maybe more difficult to acquire |

|

White PCB |

LED lighting utilizes |

Reflects light well |

Prone to staining and dirt accumulation |

Green has been the standard color of printed circuit boards for many decades, but black PCBs are generally employed in high-end electronics. Both find their niche, but they are not the same in terms of application, manufacturability, and appearance.

Green PCBs are employed most frequently since they are easier to visually inspect when they are made. It is easy to identify faults by contrasting between solder mask and copper traces. Black PCBs are nearly impossible to visually inspect. Black solder mask hides faults, meaning faults are made difficult to detect, hence the increased utilization of automated optical inspection (AOI) machines.

Black PCBs retain heat longer than green PCBs. If heat is not being dissipated, then something is wrong. Designers utilize green PCBs if a heat-sensitive process is occurring because they are more heat-resistant. Black PCBs, though, can perform just as well as long as the appropriate heat removal systems are used.

Green PCBs are cost-effective since they are mass-produced in large quantities and are easily available. Green solder masks and the substrate upon which the same is done are standardized and, hence, are cost-effective to manufacture. Black PCBs require solder masks to be deposited with accurate precision, and hence, the cost of manufacture would be a bit higher.

Black PCBs can be chosen by companies that desire their products to be unique. The new, dark look and touch give a high-end feel and thus are perfect for high-end equipment. Green PCBs, as effective and economical, do not have the visual attractiveness black PCBs offer in some consumer products.

|

Feature |

Black PCB |

Green PCB |

|

Inspection |

Challenging, needs high-level AOI |

Slightly higher |

|

Heat Dissipation |

Easier, good contrast for visual checking. |

Less costly |

|

Cost |

Can hold heat if it is badly designed |

Excellent-quality, modern look |

|

Aesthetic Appeal |

Typically improved heat performance |

Standard, widely used |

Applied on a PCB to prevent shorting and oxidation of the board, a solder mask is a protective cover layer. Protective in nature, it does affect color-based inspection, usability, and branding.

The solder mask color has a direct impact on manufacturers' ability to easily detect faults. The green color is employed during mass production because soldering faults are readily noticeable. Black PCBs demand sophisticated inspection methods due to poor solder mask-to-circuit trace contrast.

While the color of the solder mask does not contribute much to its electrical performance, heat absorption characteristics can be influenced by it. Black solder masks will absorb heat more and can be useful in temperature control in some applications. Lighter shades, such as white or blue, will have better heat reflectance and can be useful in some applications.

|

Solder Mask Color |

Pros |

Cons |

|

Black PCB |

Streamlined look, applied to high-end electronics |

Difficult to inspect, more heat is absorbed |

|

Green PCB |

Hard to check, holds heat longer |

Below-average appearance, not stunning |

|

Red PCB |

Simple inspection, cost-effective |

Slightly less frequent, moderate price increase |

|

Blue PCB |

Average looks, not remarkable. |

May be expensive |

|

White PCB |

Good contrast, visually distinguishable |

Prone to staining and dirt |

The selection of an appropriate solder mask color is dictated by functional and aesthetic considerations. Although green is the de facto functional standard, black and other colors are normally selected for product differentiation and brand recognition.

Black solder mask is the preferable solution for production in bright conditions, i.e., on auto dashboards or exterior displays. However, its ability to mask defects, such as PCB black pad defects (oxidized solder joints), does need advanced methods of inspection. Green solder masks provide the quality checks and, thus, constitute the default in mass production.

The association of black PCBs with high-end products indicates that their use goes into high-grade electronics, i.e., gaming equipment, latest technologies, and high-end car systems. Referring to all of them as "high-end" would be naive, though.

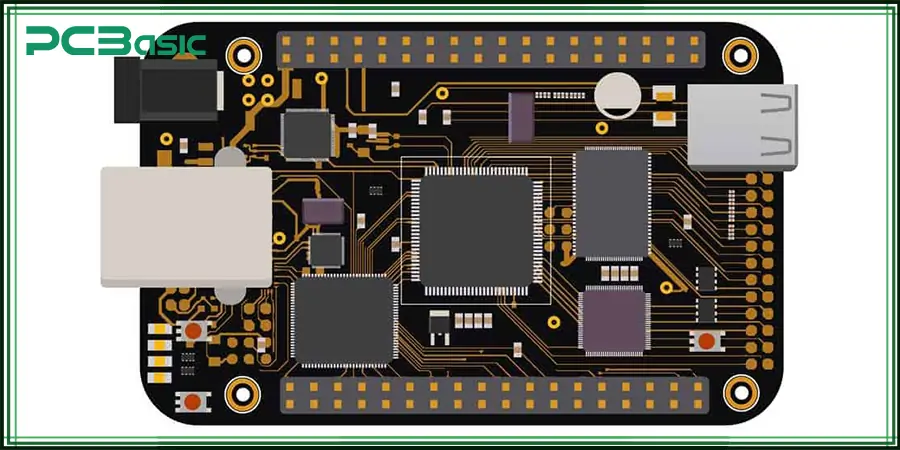

● Aesthetic Premium: Apple and NVIDIA use black circuit boards to coordinate with clean, modern designs. The matte finish is elegant.

● Technical Advantage: Black core PCBs generally employ superior grade black FR4 materials, enhancing thermal stability as well as strength. Their use in extreme environments like servers or medical equipment is justified on this basis.

● Cost Factor: More expensive than regular green PCBs, the cost is for special manufacturing—not necessarily for inherent superiority. A well-engineered green PCB can equal or even exceed the performance of a poorly constructed black PCB board.

Briefly put, black PCBs are not technically better but are selected because of technical or brand specifications. They are worth it because of the way they're designed and not necessarily because they're black.

Black PCBs' color and name still appeal greatly and generate great demand. Though they look trendy and thin and are prone to heating up, they lack the necessary test equipment unlike green PCBs, a disadvantage. Though black PCBs are more costly than others, green PCBs are produced using basic manufacturing processes.

A PCB has rather non-color sensitive performance. More practical in use are build, circuit, and material quality. Black looks or green application is irrelevant; the best solution will come from knowing each strengths and shortcomings.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.