Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Bed of Nails Test Fixture | PCB Test Tool

The bed of nails test fixture is a very commonly used testing fixture that performs in-circuit testing. It has many pinouts configured in holes existing on epoxy-phenolic glass cloth laminated sheets. This sheet was properly aligned by using pins of tools for making connections with testing pins on board and wire used for connection with measuring units. It is so-called since it is like the bed of nails with small, spring-loaded pogo pins. Here we come to different features and importance of the Bed of Nails test fixture. So let's get started.

Bed of Nails Test is a standard testing process that is employed for testing components online to find the manufacturing faults of the board and faulty components on boards through the use of electrical features of fixtures. Another name for this testing fixture is the ICT test fixture. The basic purpose of using this process is to find open circuits or short circuits or inspect the welding on board. It is mainly part of the bulk volume production of boards. The first step of this test involves online testing of the board, detecting errors or faults early and suggesting necessary changes.

In bed of nails testing, the faults are found on components connected on board and pinout, and it helps to increase efficiency and production process and reduce repair costs. It is automated testing that helps not to get services from any professionals since it is a simple and fast testing technique that can find and detect all faults on board.

Pogo Pins Arrangement

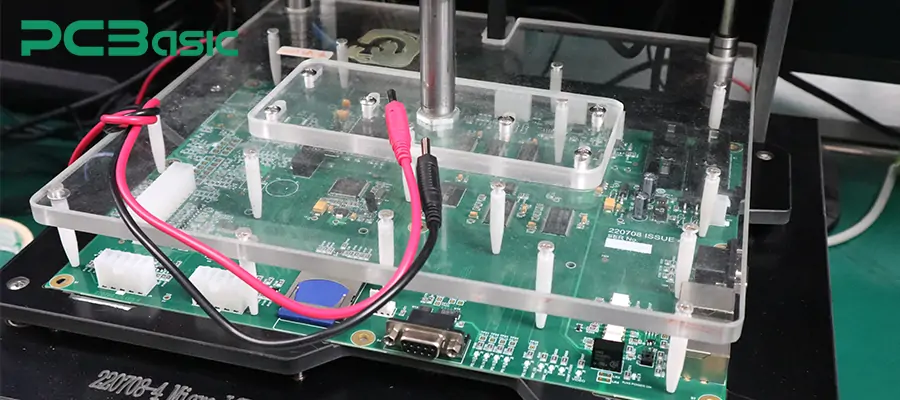

Pogo pins are configured in a grid array of rows and are compatible with board connections where testing is performed. All layouts of pins are set based on the design of the board or device under testing. The pins are at a lower distance from others, which helps to avoid short circuits between pins.

Material Selection

The base of the bed of nails test fixture is typically made from aluminum or high-density materials. Pins are made with stainless steel plated with gold, which reduces the corrosion of pins and increases conductivity. Pogo pins are insulated to avoid short circuits.

Customization Options

The fixture must be designed according to device designs that are under testing or board. There is a need to provide some options that can increase or decrease the number of pogo pins according to the device's structure. Pins are accurately labeled with relevant workings, so no wrong pins are used for any test.

Integration with Test Equipment

During the testing process, a strong connection between testing devices and pogo pins is made; wires or connectors are used for that purpose. It is also helpful for the easy flow of signals and avoiding interference and noise.

High Speed

This testing fixture increases the testing process speed, so it is the best option for using a larger volume manufacturing process since it helps to find faults fast and removes errors on board.

Reliability

This test is reliable and provides quality products since a direction connection is made with testing points, and error-free results of tests are obtained.

Low-Cost Test

While the initial setup cost may be high, the fixture can test multiple boards simultaneously, reducing overall production costs and time.

High Durable

The design of fixtures that can be used repeatedly and for a longer duration makes it a durable testing process.

No Need for Manual Process

It reduces manual testing and labor, resulting in low chances of human error.

1. Why use bed of nails test fixtures in PCB?

Testing Point easy access: The nails connect directly with the testing points on the board, eliminating the need for additional wiring, which simplifies the inspection process. So make a simple inspection process.

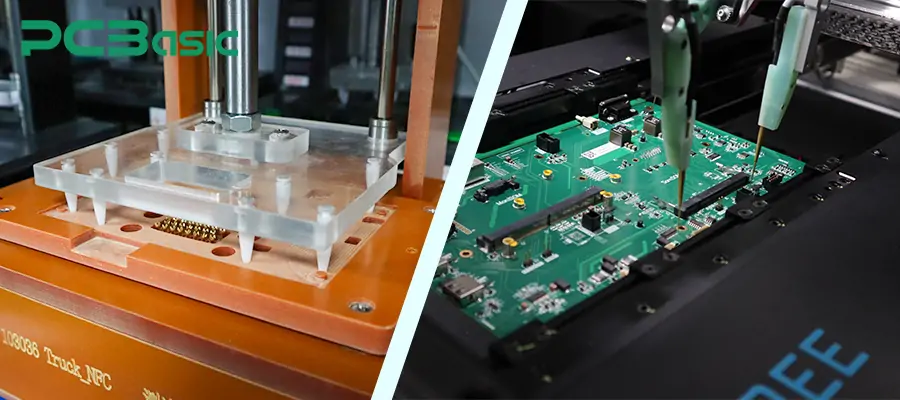

Variable design of nails: The nails are designed to be easily customized according to the testing points, ensuring optimal connections to the board. Hybrid flying probes are used for such configurations.

Opens/Shorts Circuits: The spring pin array helps to check the current flow in the circuit and find any short or open components on board, as well as solder bridges.

2. How Do Bed of Nails Fixtures Operate in PCB Testing?

First, the PCB is placed in the testing fixture, and a button is pressed to lower the mechanical hood onto the fixture using a pneumatic slide. Electrical probes of the hood make a connection with the PCB board, and with the use of the testing sequence board, automated tests started. With the use of high-speed data acquisition, testing data is recorded. And the report of the test has data for the pass or failure of the test.

3. Customization of Bed of Nails Fixtures

The design of nails for bed fixtures is such that their functions can be set according to board design requirements. If the board design needs low or high pins, you can easily modify the pogo pin numbers according to the design. It also has features for removing the testing points if needed for some boards.

|

Aspect

|

Bed of Nails Test

|

Flying Probe Test

|

|

Testing Method

|

Uses a fixed array of probes to contact test points on the PCB

|

Uses a few mechanically controlled probes to test PCB points

|

|

Speed

|

Suitable for high-volume production; fast testing

|

Slower testing, suitable for low-volume or prototype designs

|

|

Cost

|

High initial fixture cost, but low per-board testing cost

|

Low fixture cost, but higher per-board testing cost due to longer time

|

|

Flexibility

|

Fixed test point layout, not suitable for frequent design changes

|

Highly flexible, easily adapts to different designs

|

|

Testing Precision

|

Lower precision, mainly detects shorts and opens

|

Higher precision, capable of measuring resistance, capacitance, etc.

|

|

Application

|

Ideal for mature designs and high-volume PCB production

|

Suitable for prototype designs, small batches, or design validation

|

|

Mechanical Damage

|

May cause slight dents or mechanical damage to the PCB

|

Almost no mechanical damage to the PCB

|

|

Automation

|

Suitable for automated mass production testing

|

Less automated, often used in lab testing

|

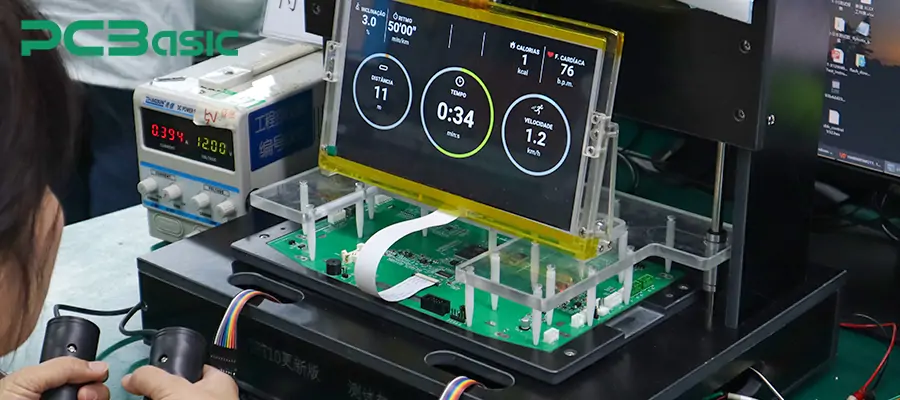

PCBasic's test fixture is customized according to the unique requirements and parameters of products. It helps to make reliable and strong connections with testing pins and provides accurate and effective testing results. With the creation of such fixtures that are according to certain layout and board functions, PCBasic helps to get error-free results for tests. As a result, you can get high-quality and rapid production of your products.

PCBasic comes with fixture services for prototype PCB assembly and large electronic projects. We do not compromise on high-quality standards for each product or component.

Although there are many tools and instruments used in PCB manufacturing and testing, the bed of nails test fixture remains a crucial tool. It offers unique testing and design features that help to make reliable and high-quality boards. So it is mostly used for processes where high accuracy and reliability are needed. This technique is also helpful for providing low-cost testing features and reliable products. It is mainly used in in-circuit testing to check the components connected on the board without disconnection and make sure that all components are working well and do not have any short circuits or open circuits. Additionally, it can be used to perform various tests, including isolation, resistance, and continuity tests on the board.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

1. How does the setup of the bed of nails enhance PCB testing efficacy?

This PCB testing increases the efficiency by providing high-speed detection of faults and correction of these errors on board. It provides accurate results.

2. How often should fixtures be maintained, and what does it involve?

Do a proper inspection of the fixture to avoid wear and corrosion, and clean pins regularly to make strong connections during the test. Normally, pogo pins handle 100,000 compression cycles when needed to be replaced with a new one.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.