Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

PCBasic PCB assembly services expedite your demand-to-market after design files passed to us. Free DFM checks to find design slips, components sourcing from famous agencies, robust PCB assembly manufacturing process and 100% final inspection can ensure safe and quick delivery without any hassle. We have rich experience of PCB assembly for industries such as medical, system controller, IOT, solar power, communication, consumer digital, electrical etc. and have achieved ISO9001:2015, ISO13485, IATF16949, ROHS, SGS certificates.

Oven

Humidity Sensitive Components Storage Box

Intelligent Material Rack

We have reached cooperation with Yunhan core city,MAOZe electronics and other well-known platforms; Ensure the quality of PCBA from the source.

Collecting Data and Compute/Control Switches

control energy storage/consume between solar panel and lithium battery

manage SFP 10km communication between stations

mainboard to control inspect and print report of blood analysis

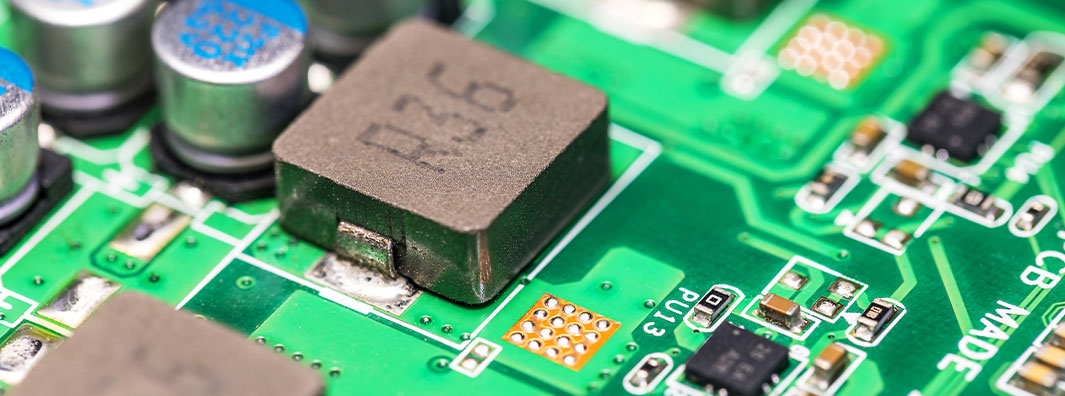

Identifying circuit board components and soldering components on PCB is crucial during SMT and PCBA process. At PCBasic, we can check and confirm the quality of SMT components, PCB board components, and other related circuits board parts. All our PCB components are sourced from quality suppliers and partners around the globe.

Printed circuit board components, PCB components, and other PCBA parts are required to pass quality testing. At PCBasic, we test each PCBA component ensuring quality and functionality during multi-stage testing protocols. The circuit board components and PCBA parts that failed the test won't be used, and only after confirmation of functional PCB components and PCBA components can we proceed to the assembly stage.

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.