Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Quick Turn Prototyping Service from PCBasic - PCB Prototyping

In the rapidly evolving electronics industry, quick turn prototyping (also known as quick-turn prototyping) is essential for companies to stay ahead of the curve, and quick turn prototyping is one of the most effective ways to accelerate product development. This can be said that PCB prototype service plays an important role in the process of maintaining a leading position. Today, I'm going to introduce you to PCBasic, a manufacturer that specializes in small and medium batch PCB assembly, which provides good and quick PCB prototyping services that have helped many companies in the electronics industry and other industries achieve quicker turnaround. Whether you are developing rapid prototyping, conducting a PCB assembly prototyping project, or require quick turn PCB prototyping services, PCBasic provides a reliable solution to meet your prototyping needs.

First, let's take a look at PCB prototyping. PCB prototyping refers to the rapid creation of prototypes, usually printed circuit boards (PCBs), in a short period of time to test designs before moving on to mass production. This method is highly effective, cost-effective and critical for engineers and product developers who need to quickly validate the functionality of a product or concept. Then, let's take a look at the differences between quick turn prototyping and traditional PCB prototyping.

|

Feature |

Quick Turn Prototyping |

Traditional PCB Prototyping |

|

Turnaround Time |

Typically completed within 24 to 72 hours |

May take several days or even weeks |

|

Cost |

More cost-effective due to smaller volumes |

Less cost-effective for small batch production |

|

Prototyping Speed |

Very quick, ideal for urgent projects |

Slower, typically used for larger-scale production or complex designs |

|

Production Volume |

Low to medium-scale production |

Suitable for large-scale production |

|

Customization |

Highly customized for each prototype |

Limited to specific design choices and requirements |

|

Technology Used |

Uses advanced equipment such as quick-turn electronic prototyping and PCB assembly prototyping |

Uses more traditional methods and tools |

From this table we can see that quick turn prototyping is ideal when time and speed are the key factors, while traditional methods are usually more suitable for slightly less urgent situations or larger scale production.

Quick turn PCB prototyping helps companies get to market quickly:

Quick-turn PCB prototyping reduces prototyping time and helps companies quickly iterate and adjust designs before they start mass production. By reducing the time it takes to prototype and test, rapid prototyping services accelerate innovation and help companies bring products to market quicker than their competitors.

Cost-effective:

Rapid PCB prototyping is often more cost-effective than traditional production methods, especially when dealing with small batch PCB manufacturing. This manufacturing approach avoids high setup costs and large-scale production runs, allowing companies to test designs with minimal financial risk.

Strong flexibility:

Quick PCB prototype design time, low cost, flexible initial test adjustment design. In this way, companies can quickly change direction without incurring the costs and delays associated with large production runs.

High product quality:

If there is a defect in the product design, using rapid prototyping can help the company find it early and improve it early. Engineers can also test real-world features early and fine-tune designs before mass production.

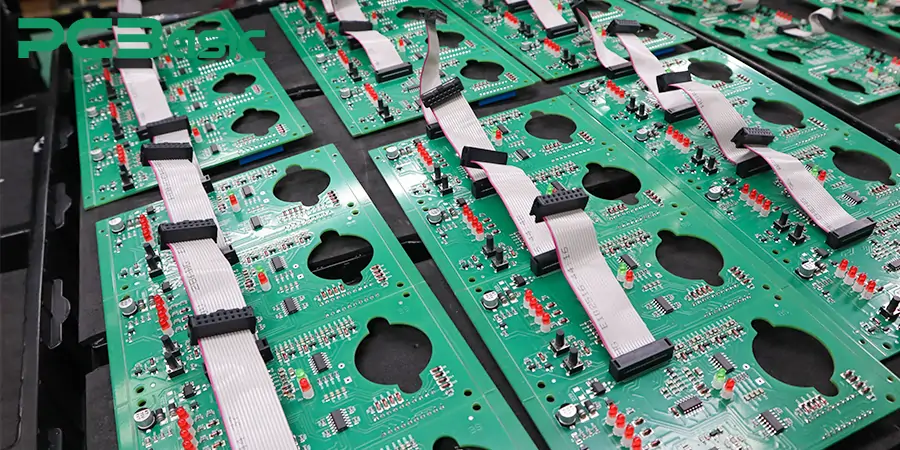

PCBasic offers a full range of PCB prototyping services, including quick-turn prototyping and quick-turn PCBA prototyping. PCBasic's advanced PCB assembly capabilities ensure quick PCB assembly turnaround times while handling even the most complex PCB designs. Whether you need to develop rapid prototypes for consumer electronics devices or prototype PCB assemblies for highly specialized applications, PCBasic has you covered. "PCBasic is a manufacturer focused on small and medium volume PCB assembly and has been in the PCB assembly industry for more than 15 years. If your quick turn PCB prototyping needs to be mounted, please contact us, we will treat each of our respected customers with speed and professional attitude. Learn more about PCBasic’s quick-turn PCB assembly."

Quick turn prototyping is a very effective way to help companies accelerate product development cycles. With PCBasic's quick PCB assembly prototyping service, you can quickly complete your product development as well as testing, ensuring high quality results at every stage. Contact PCBasic today to start your prototype project!

Assembly Enquiry

Instant Quote