Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: A High-volume PCB Assembly Manufacturer

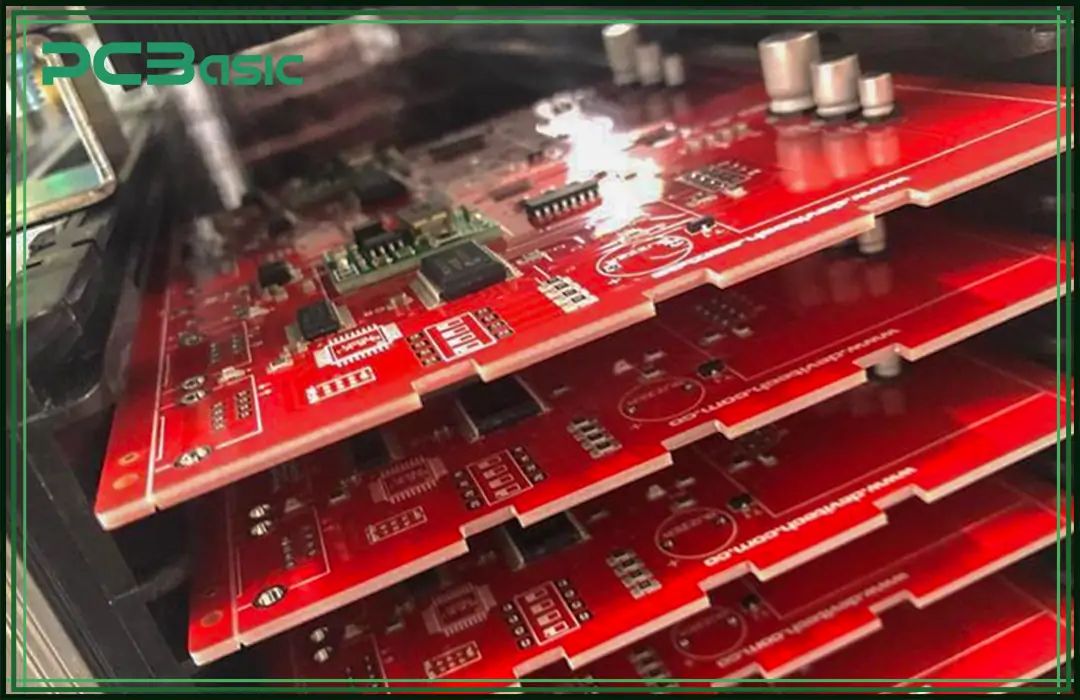

As the name indicates, high-volume PCB assembly means manufacturing printed circuit boards (PCBs) in bulk in a single production cycle. The number of PCBs in high-volume PCB assembly could be thousands or tens of thousands at once.

Moreover, a high-volume PCB assembly manufacturer uses automated techniques to maintain quality and improve efficiency. High-volume PCB assembly is often used to produce electronic devices like laptops and smartphones.

Below are the key characteristics of high-volume electronic PCB assembly:

The high-volume PCB assembly manufacturer can produce PCB assemblies in batches of thousands and more per run. The bulk production does not harm the quality of the products. They are as efficient and thoughtfully produced as a single item.

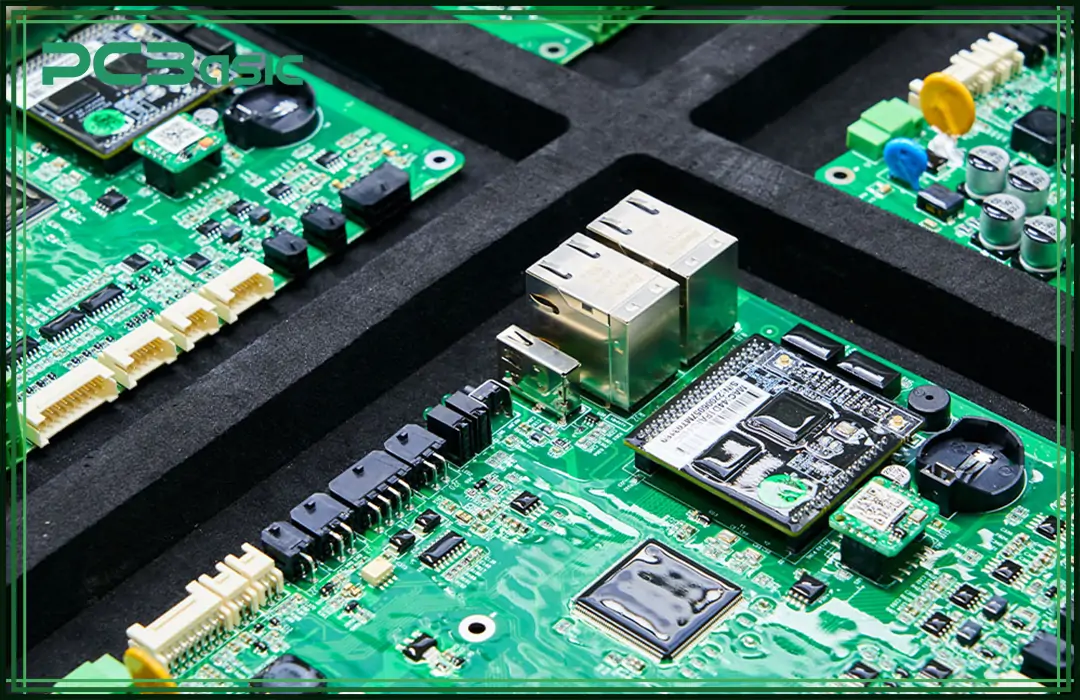

The whole process of high-volume PCB assembly is automated. Machines place circuit board components, solder them and inspect them to ensure speedy production and consistent quality. The automated process minimizes the chances of error and maximizes the production number.

Circuit board assembly requires careful measures at each step. A thorough quality check is mandatory, including in-circuit testing, automatic optical inspection (AOI), visual inspections, X-ray inspections, and functional testing. All this is rigorously done and followed in high-volume PCB assembly manufacturing.

A high-volume PCB assembly manufacturer ensures massive uniform production and the same quality standards.

If you want the quickest printed circuit board assembly in massive production, high volume is the finest solution, even under tight deadlines.

A high-volume PCB assembly manufacturer has trusted suppliers who can provide quality products at reasonable prices. You can leave the fuss to manufacturers and focus on more critical tasks.

High production volume means less production cost per unit.

Besides, a few critical considerations for high-volume PCB assembly include component selection, the manufacturing capabilities of the PCB assembly house, design optimization options, and quality assurance protocols.

Considering all these, PCBasic can be your trusted PCB assembly partner.

PCBasic believes in perfection and keeps raising the bar by collaborating with PhD teams from multiple universities for industry-academia research. They have led the PCB assembly manufacturing for 10+ years with a highly efficient project management team.

Here are the industries PCBasic serves:

● Consumer Electronics: PCBasic is a master of PCB prototyping and bulk production, making it an ideal choice for electronic devices. Particular sub-niches include smartphones and home appliances.

● Automotive Electronics: PCBasic is the go-to manufacturer for automotive systems, including advanced driver-assistance systems, control units, and sensors.

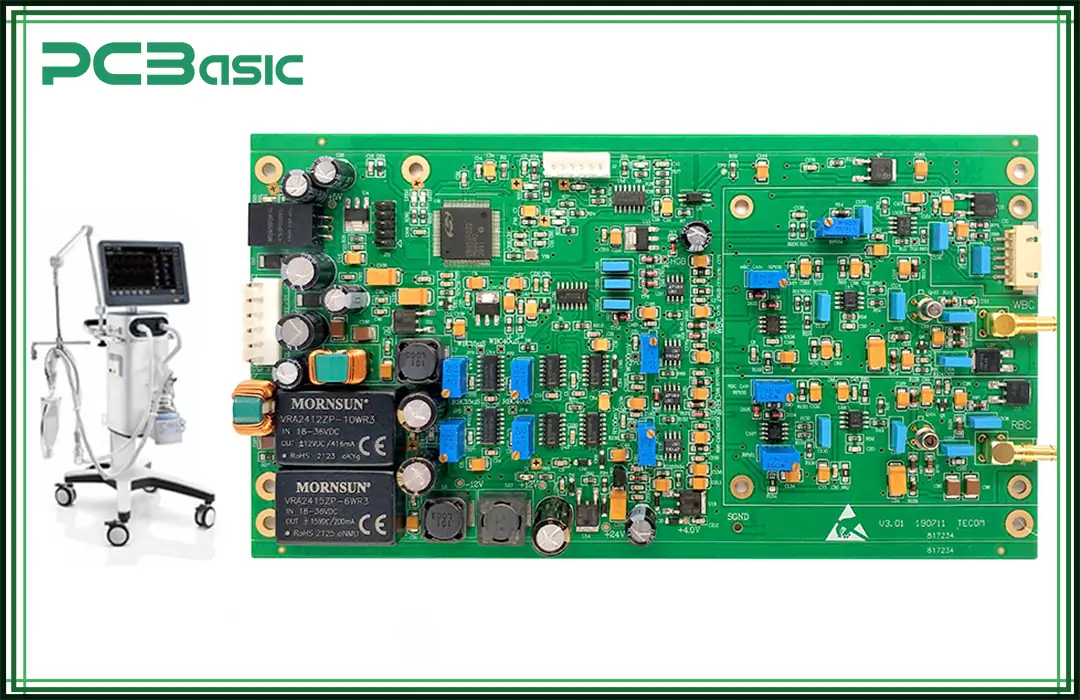

● Medical Devices: The powerhouse of PCB assembly also offers precise box-build assembly and SMT PCB assembly for medical devices.

● Telecommunications: Looking for a trusted high-volume PCB assembly manufacturer for complex signal routing, high-frequency PCBs, or antennas? PCBasic does it all.

● Aerospace: This PCB assembly house handles the demands of aerospace applications efficiently. It provides the PCB assembly solutions that best fit the industry's requirements.

Here is why you should choose PCBasic for high-volume PCB manufacturing:

PCBasic has multiple factories at different locations to fulfill the diverse production needs of its clients.

● Shenzhen Small-Batch Factory – Best for scale production and prototype testing, ensuring precision and flexibility.

● Huizhou Large-Batch Factory – Meant for mass production and best for large orders. Further, it is equipped with state-of-the-art assembly lines to handle massive orders efficiently.

Moving on, PCBasic has a self-operated stencil and fixture factory. It enables precise and high-quality assembly. Being capable in-house, PCBasic ensures fast production time, better quality control, and cost-effectiveness.

CNC precision parts processing is ultra-accurate for advanced PCB designs. It ensures improved performance. Besides, this technology improves the overall quality of the PCB assembly.

The super-efficient team at PCBasic guarantees stencil delivery within one hour. It significantly reduces lead times and accelerates production cycles.

PCBasic has a central warehouse for intelligent electronic components. The management ensures a streamlined supply chain and reduces component shortages. No production delays and more efficient operations.

PCB assembly relies on high-quality components. PCBasic provides original parts. Moreover, they guarantee reliability and authenticity. Quality material reduces the risk of pirated components while assuring compliance with industry standards.

PCBasic believes in making every possible effort to help its clients. A one-click Bill of Materials (BOM) import system and an instant quoting tool are the outcomes of this effort. This feature lets customers get quick price estimates. They can easily place orders without any delayed response.

PCBasic, being the national high-tech enterprise, deals utilizing the highest quality management systems. The high-volume PCB assembly manufacturer holds certifications like ISO 13485, IATF 16949, ISO 9001, ISO 14001, and UL Certification.

Are you looking for a reliable, high-volume PCB assembly manufacturer? Look no further and trust PCBasic for your projects. They are the leading manufacturers in the region, providing efficient services to various clients. Their quality work needs no testimonial as it speaks for itself. Whether you belong to the automotive industry, medical, consumer electronics, telecommunication, or aerospace, PCBasic has got you covered.

Contact the customer service team today to get the quickest quotation and consultation.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.