Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: A Professional Prototype PCBA Manufacturer

In the field of electronics manufacturing, the PCBA prototype is the key role of the PCBA before mass production. It plays a vital role as a bridge between design and mass production.

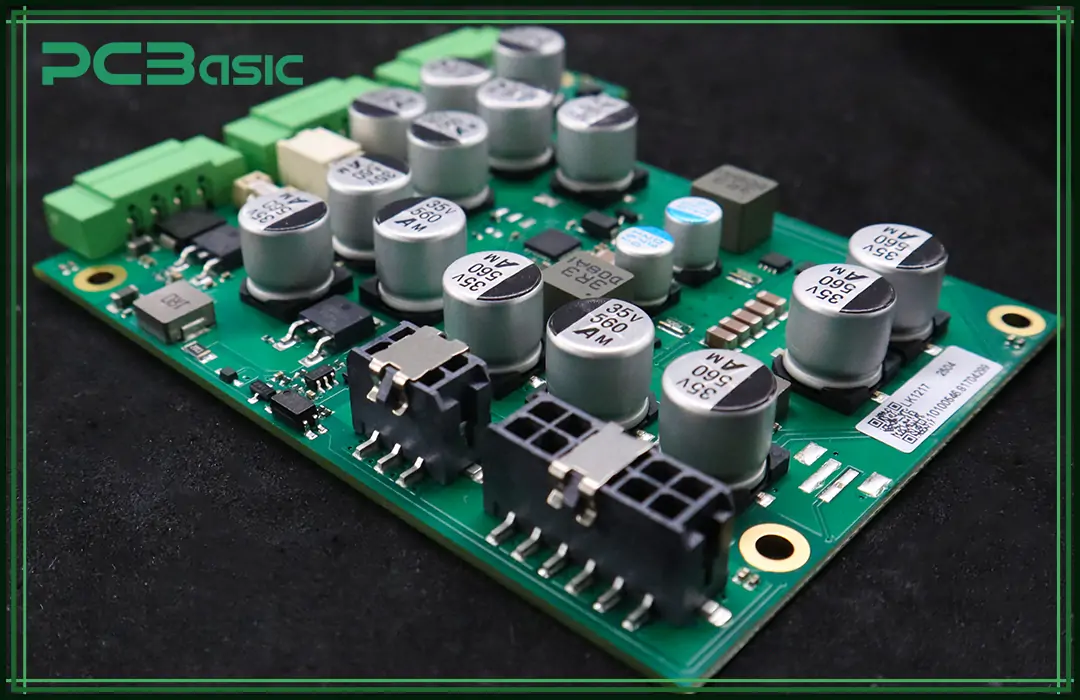

A professional and reliable wholesale PCBA prototype assembly supplier can guarantee the quality of your products. PCBasic has more than 10 years of industry experience. It is a trusted China PCBA assembly prototype manufacturer. At PCBasic, it provides high-quality electronic circuit boards and the cheapest PCBA prototype services to customers around the world.

A PCBA prototype is a PCBA board prototype used to test and verify circuit designs. Its main purpose is to ensure that the function and performance of the circuit meet the design requirements and can run stably in practical applications. In the process of electronic product development, the prototype stage is very important. In this process, engineers can detect potential problems before mass production, thus avoiding costly production losses due to design defects.

Before mass production, engineers and manufacturers use prototype PCB DIP PCBA and SMT PCBA to help verify product designs. The tests include the reliability of component soldering, the stability of the circuit, and whether the entire PCBA design meets the expected operating conditions. If a problem in circuit design, soldering process or component selection is found at this stage, it can be adjusted in time. This saves time and cost in subsequent mass production and reduces rework or scrap.

A reliable prototype PCBA supplier must have a precise production process. Besides this, it should ensure that the wholesale PCBA prototype assembly is manufactured in accordance with industry standards such as IPC, ISO and UL certifications. This means that suppliers not only need to have high-precision SMT and DIP assembly capabilities, but also need to have a strict quality control system to ensure the performance stability and consistency of each PCBA board prototype. Professional manufacturers who can provide a wide range of PCBA prototype solutions are key to ensuring product success.

Using prototype PCBA services offers a lot of benefits, especially in product development, quality control and market competitiveness.

1. Cost Savings:

In the development of electronic products, design defects that are discovered after mass production can result in significant financial losses, including rework costs, wasted materials, lost downtime, and damaged brand reputation. Therefore, through testing and verification in the PCBA prototype phase, engineers can identify problems in circuit design, component compatibility, or soldering process at an early stage. The cost of fixing these problems is much lower than correcting them after mass production, while avoiding the risk of massive product recalls.

In addition, PCBasic provides the most reliable and cheapest PCBA prototype service, which can help enterprises obtain high-quality PCBA board prototypes while controlling costs, ensure the stability of product design, and be fully prepared for subsequent mass production.

2. Fast Turnaround Time:

In a competitive market environment, time is money. Enterprises hope to complete product development and marketing as soon as possible. Choosing a supplier with fast PCBA prototype capabilities can effectively shorten product development cycles.

PCBasic has a small-batch factory in Shenzhen and a large-batch factory in Huizhou, which can provide flexible production mode according to customers’ needs, and has a central warehouse of intelligent electronic components to ensure the rapid supply of components and accelerate the production schedule.

At the same time, PCBasic's SMT steel 1-hour delivery service makes SMT assembly more efficient and further reduces the time for wholesale PCBA prototype assembly. For companies that want to accelerate product iteration and go to market, choosing PCBasic's Chinese PCBA assembly prototype service is the best choice.

3. Design Validation:

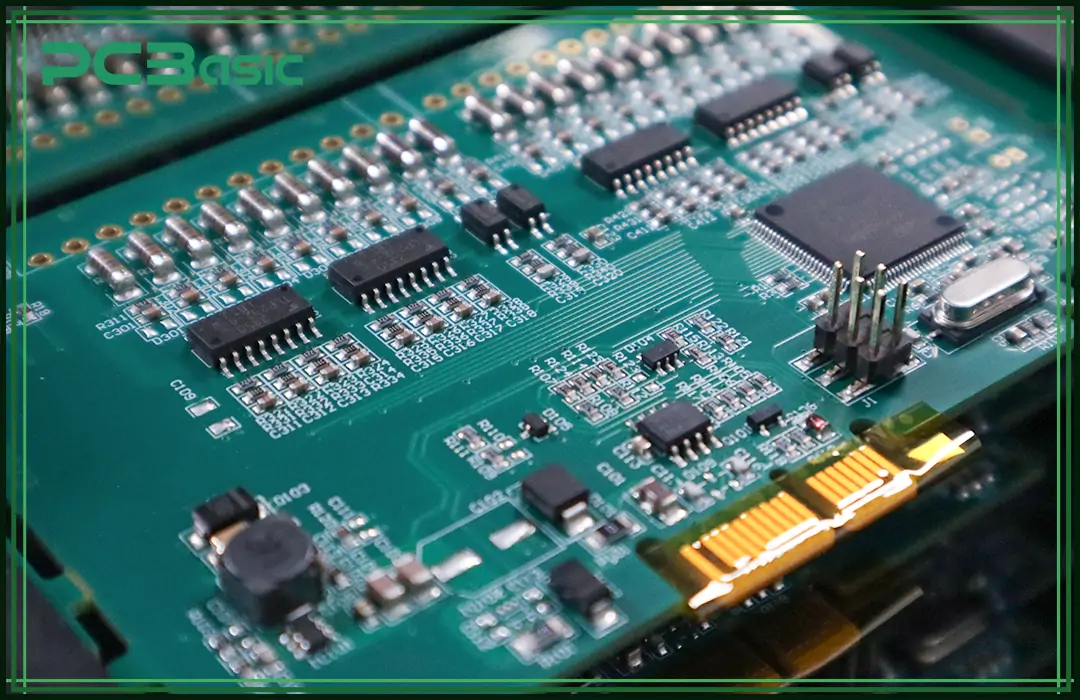

One of the main purpose during the PCBA prototype stage is to verify the feasibility of the circuit design. Through prototype PCB DIP PCBA and SMT PCBA, enterprises can test the functionality of the circuit board in the initial stage, check signal integrity, power management, and component matching.

During this process, engineers can ensure that the circuit works as expected through actual operation tests. If any situation that does not meet the design requirements occurs, the design can be adjusted in time to avoid mass production failure due to design flaws.

4. Improved Reliability:

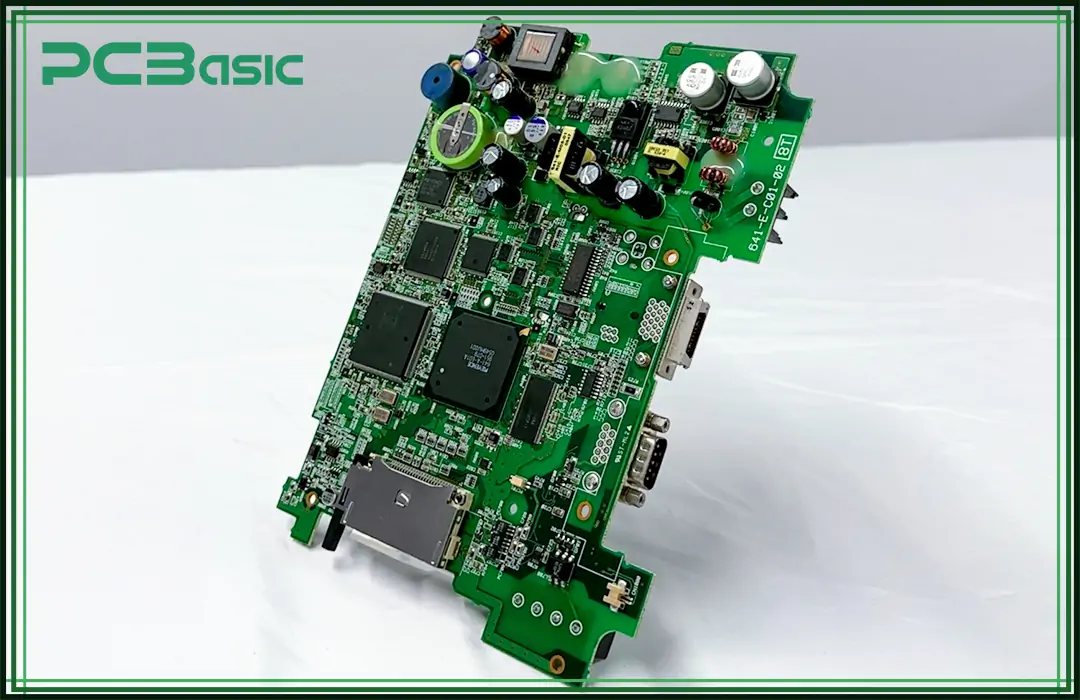

The reliability of electronic products directly affects its market competitiveness and user experience. Through continuous iterative testing, companies can optimize board design, improve soldering processes, and ensure product stability in a variety of environments. For example, in the LED PCBA prototype, good thermal management and power control are essential to improve LED lifespan. In the field of industrial control, the anti-interference ability of the circuit board determines the long-term reliability of the equipment.

As a professional PCBA prototype supplier, PCBasic enforces strict quality control measures, backed by ISO13485, IATF 16949, ISO9001, ISO14001, UL certification, to ensure the long-term stability and high reliability of products.

PCBasic stands out as a leading prototype PCBA supplier. It offers reliable and cost-effective solutions. Its China PCBA assembly prototype services are trusted by global customers for their precision, quality, and affordability.

At PCBasic, you can get:

• Cheapest PCBA prototype service with no compromise on quality

• Prototype PCB DIP PCBA and SMT assembly for different applications

• Fast PCBA prototype production with quick turnaround

• Access to an intelligent electronic components central warehouse

• One-click BOM import and instant quoting system

Whether you need the cheapest LED PCBA prototype service or an advanced wholesale PCBA prototype assembly, PCBasic ensures that your project gets the best solution.

When it comes to reliable and efficient prototyping services, PCBasic is a standout choice among global manufacturers of fast PCBA prototypes, offering everything from design validation to large-scale production support. Whether you need a quick turnaround or cost-effective solutions for your electronic projects, their expertise in handling complex designs ensures success at every stage.

Choose PCBasic today for your next PCBA prototype project, and experience the difference that professional service can make!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.