Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > A Comprehensive Guide to the QFN Package

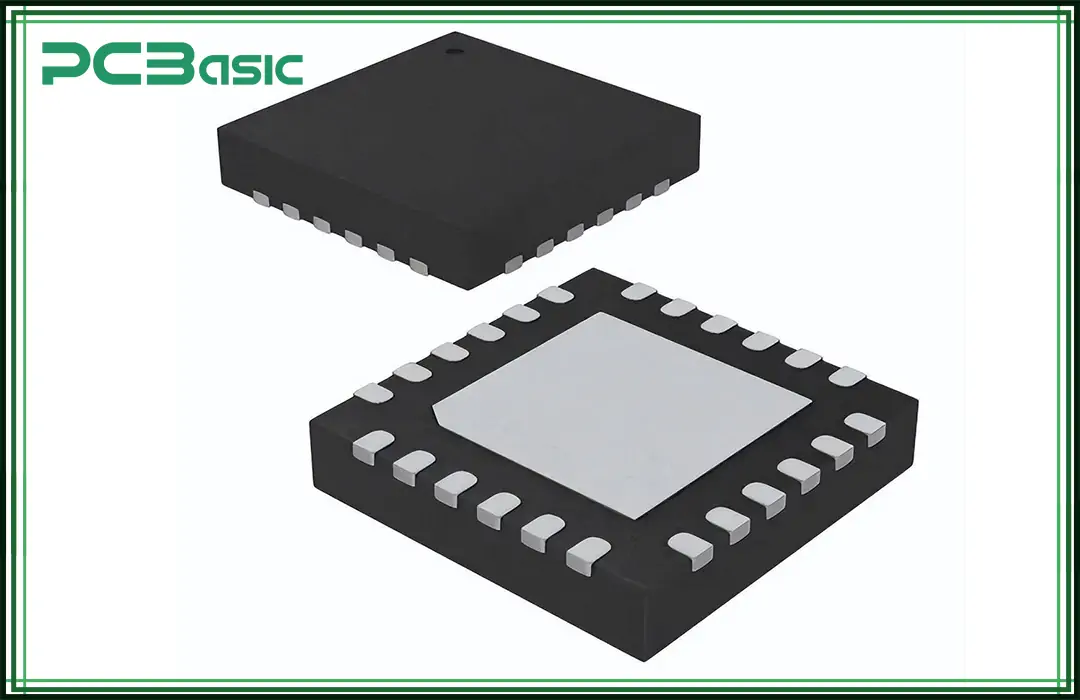

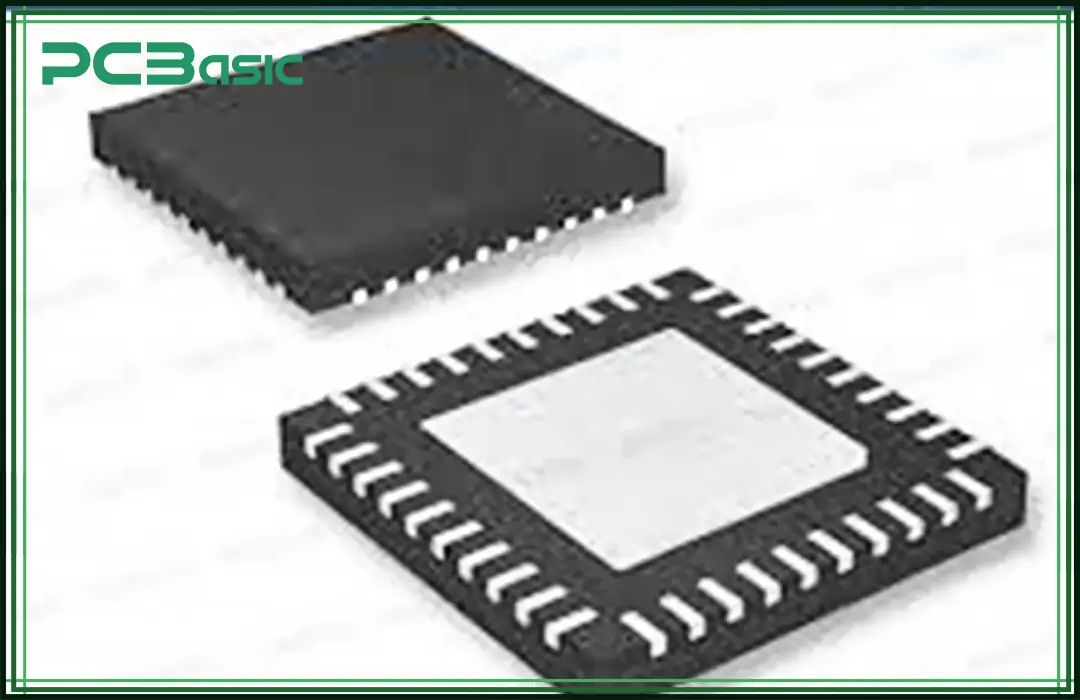

The QFN package is very small and without any outer leads. This package has pads instead of leads. It significantly improves the performance and reliability of small devices. The QFN chip package is mostly preferred in semiconductors for three major reasons, which are:

QFN packages serve as a connection between integrated circuit chips and PCBs. Therefore, it ensures low signal loss for better performance.

QFN Package Overview; the QFN package connects silicon chips to a PCB using surface-mount technology. QFN packages feature edge pads with a bottom solder pad. They enhance thermal management and electrical efficiency compared to traditional leaded packages.

A QFN chip package typically consists of:

● Lead Frame: This is the key to the IC’s performance. It’s the base of the package.

● Single or Multiple Dies: These are the silicon chips inside the package and are attached to the PCB using a surface mount.

● Wire Bonds: These are usually copper or gold. These wires connect the lead frame to the dies.

● Molding Compound: The molding compound protects the chips inside the package from damage and helps maintain performance.

There are many different QFN packages. Each type is designed for a specific use. Below are some of the most common QFN package types.

The Standard QFN is the most common type. It’s used in many household electronics. These packages are not too big or too small. They handle heat well and fit into many different types of devices. Standard QFN is often used in products like televisions, gaming consoles, and even car systems.

Tiny TQFN packages, about the size of a dime, are designed without traditional leads, significantly enhancing reliability. These ultra-small chips are ideal for space-constrained devices like hearing aids, where performance and minimal failure rates are crucial.

TQFN chips have strong thermal and electrical performance. This improves heat management and reduces battery drain, a common issue in cordless devices.

What is the meaning of the VQFN package? If you expand the acronym, it means Very Thin Quad Flat No-lead. To your surprise, it is thinner than the DFN package. These are integrated into more small digital devices. A few common examples are fitness trackers, thin smartphones, and wireless earbuds.

VQFN packages are good at handling high-speed signals. This makes them important in fast devices, helping them work quickly.

The WQFN package is the acronym of Wettable Flank Quad Flat No-lead. The special thing about this package is its edges. These edges are like flanks. So what is the function of these flanks and why do manufacturers use them in devices?

This is the main question. So you know, in PCB manufacturing, inspection is very important after the soldering process. WQFN package makes the inspection process extremely easy. Sometimes, during PCB assembly, soldering result in some issues in joints. So with this package, engineers can detect potential flaws effortlessly.

HQFN (Heat-sink Quad Flat No-lead) packages are surface-mount integrated circuit packages used in electronic devices. So, you see, they have exposed pads on the bottom for better heat dissipation. In simple words, they're flat with no protruding leads. This point is important: HQFN packages save space on circuit boards. Simultaneously, they provide excellent thermal performance for power-intensive applications.

Below, you will read a precise comparison of the different QFN chip package types:

|

Type |

Size |

Key Feature |

Common Uses |

|

Standard QFN |

Medium |

You can control heat |

Domestic electronics |

|

DFN (TDFN) |

Thin |

Fewer terminals save space |

Small devices |

|

VQFN |

Very Thin |

Very slim |

Smartphones |

|

WQFN |

Medium |

You can inspect the solder |

Automotive |

|

TQFN |

Ultra-thin |

Smallest size |

Listening devices |

What does this table convey? You have precisely read the comparison of every package type. His comparison table will help you get an extract of all the packages. So you can choose wisely.

Now this is time to compare QFN with QFP. QFP belongs to the old school. It was used in classic devices. However, QFN packages are all above in terms of performance and leads.

Go back about two decades. QFP packages were pretty popular in classic devices. They were heavy, slow, and space-consuming. Where you can find such packages. Do you have an old Sony TV in your home? Just try to operate it and you will find gull-wing terminals. The con of this package is exposed leads. These edges are vulnerable to cracking and bending.

Here’s a quick look at the differences between QFN and QFP:

|

Feature |

QFN Package |

QFP Package |

|

Leads |

No leads |

Leads on all sides |

|

Size |

Small |

More space consuming |

|

Heat Control |

Excellent heat control |

heat control is average |

|

Solder Inspection |

Hard to inspect (unless WQFN) |

Easy to inspect |

|

Common Uses |

Phones and tablets |

TVs, computers & machines |

What have you noticed in this table? QFN has no leads, but they can control heat effectively. Whereas QFP is surrounded with leads and heat control is also poor. However, later, it is easier to inspect.

So let's conclude everything you have read above. QFN packaging is everywhere in electronic devices. In contemporary technology, precise QFN packages have become a must-have element for making small and compact devices. However, one needs to understand the basic functions of every package so you can use it following your requirements.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.