Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Prepreg in PCB Manufacturing

In the manufacturing process of a multilayer PCB, prepreg plays a key role in the connection and insulation of the interlayer board. In this blog post, let’s learn about:

• What PCB prepreg is;

• The importance of PCB prepreg;

• PCB prepreg use, material composition;

• PCB prepreg vs. core.

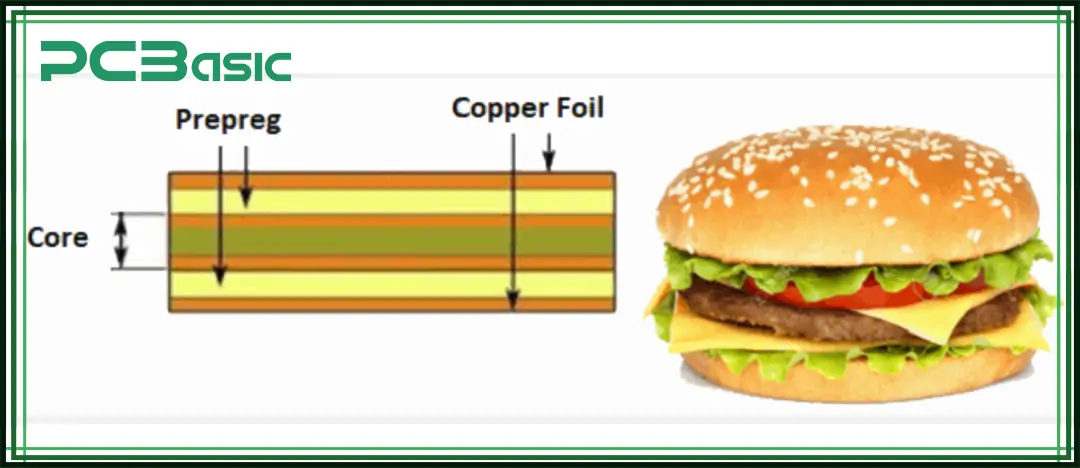

PCB prepreg is an important material used in the manufacture of multilayer circuit boards. It looks like a piece of cloth, but is actually made of fiberglass cloth that has been pre-soaked with a layer of resin, such as epoxy or polyimide. But the resin is not completely hard, it’s in a partially hardened state, somewhere between liquid and solid.

To put it simply, prepreg is like a layer of adhesive tape that has not fully dried, but can soften, flow and harden at high temperatures.

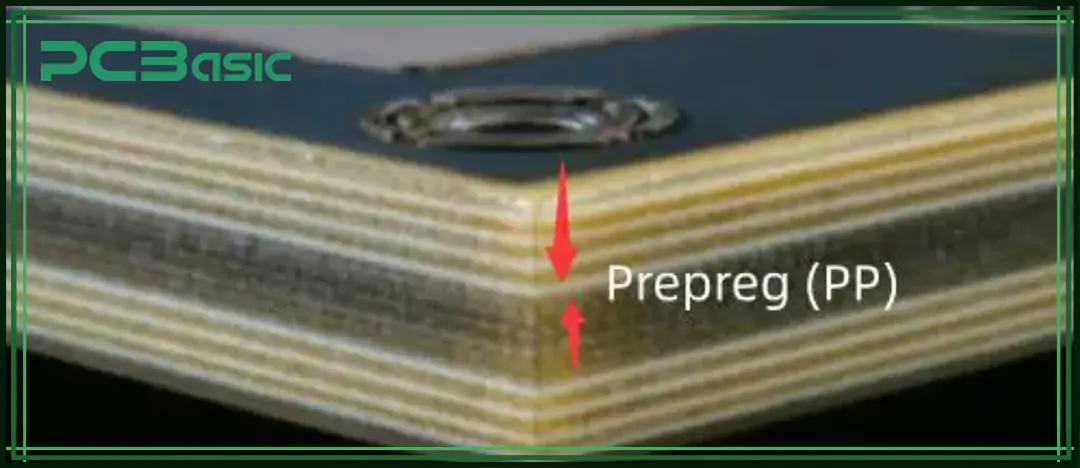

In the structure of a multilayer PCB, signal layers, power layers and ground layers are usually distributed on different levels. They need to be firmly connected to ensure electrical continuity and at the same time being effectively isolated to prevent signal interference or short circuits. The important material that achieves this function is prepreg.

In the manufacturing process, PCB prepreg is used to fill and bond the gaps between PCB cores and copper foil, or for the combination of multiple PCB cores. It is more than just an adhesive; it also performs several key functions.

• Mechanical Strength:

After lamination, the cured prepreg material firmly fixes all layers, making the entire circuit board structure strong and not easy to deform.

• Electrical Insulation:

There must be electrical isolation between each layer of circuit boards. Prepreg has good insulation performance to avoid signal crosstalk or circuit short circuits.

• Dimensional Stability:

High-quality PCB prepreg will not shrink or expand significantly under high temperature and pressure environments, ensuring the board's dimensional accuracy.

• Uniform Dielectric Properties:

Uniformly distributed resin ensures that there are no sudden changes during signal transmission, improving signal integrity throughout the PCB.

We can say that without this prepreg material, the multilayer circuit board cannot be effectively pressed together, and the connection between the layers is not stable, nor can the necessary insulation function be achieved, which may eventually lead to an unreliable or non-functional board.

High-quality prepreg materials in PCB manufacturing must not only play the role of connection and insulation, but also meet a variety of electrical and mechanical properties to ensure the stability and reliability of the board.

• Dielectric constant (Dk):

This value indicates how prepreg material affects the electric field. The lower the Dk, the faster the signal is transmitted in the board and the smaller the signal distortion. For high-speed digital signals, maintaining a proper Dk is critical.

• Dissipation factor (Df):

This parameter represents the energy loss of the signal during transmission. The smaller the Df, the less attenuation of the signal as it passes through the PCB prepreg, which is particularly suitable for applications where signal integrity is required, such as high-speed data communications or RF lines.

• Glass transition temperature (Tg):

Tg is the temperature at which the material changes from "hard and brittle" to "soft and flexible." The higher the Tg, the higher the temperature resistance of the material, and it is more suitable for use in high-temperature soldering and complex processes and less likely to deform or fail.

• Resin content and flow:

The ratio of resin affects the bonding strength between layers. If the resin is too little, it will not stick firmly; too much may create bubbles or holes. The prepreg material with suitable flowability can be evenly spread out during lamination to form a stable structure.

Thanks to these excellent characteristics, high-quality PCB prepreg performs exceptionally well in high-speed digital circuits, RF (radio frequency), and microwave communication applications, ensuring fast, accurate, and long-term reliable signal transmission.

There are many types of common PCB prepreg. Different materials have different characteristics, used in different occasions. The choice of which prepreg material depends on where your circuit board is used, temperature, whether the signal is high-speed, and if there are environmental requirements. Here are several common PCB prepreg types, let's take a look at them.

• FR4 Prepreg:

It is the most common one, which is made of epoxy resin and glass fiber. It is affordable, stable and suitable for most common circuit boards, such as household appliances, industrial boards and so on.

• High-Tg Prepreg:

This material has stronger high-temperature resistance. It is not easy to deformation or failure because of heat, and is suitable for use in high-temperature occasions, such as automotive electronics, LED lighting and so on.

• Low-Dk / Low-Df Prepreg:

This material is specifically designed for high-speed, high-frequency signals. The lower the Dk, the faster the signal travels; the lower the Df, the smaller the signal loss. It is commonly used in 5G equipment, RF modules, high-speed data communication, and other products with high signal quality requirements.

• Polyimide Prepreg:

This material has very good heat resistance and can work stably for a long time even in a high temperature environment. It is suitable for high-temperature and high-reliability occasions such as aerospace, military and engine control systems.

• Halogen-Free Prepreg:

This PCB prepreg is halogen-free and more environmentally friendly, especially suitable for products that need to meet RoHS or green environmental requirements. Even if it is burned during disposal, it will not release harmful gases.

Simply put, different prepreg materials are suitable for different products. If your PCB operating temperature is high, signal speed is fast, or the product to export to Europe is in line with environmental standards, you need to choose the corresponding material in order to ensure that the circuit board performance is good, long, no problems.

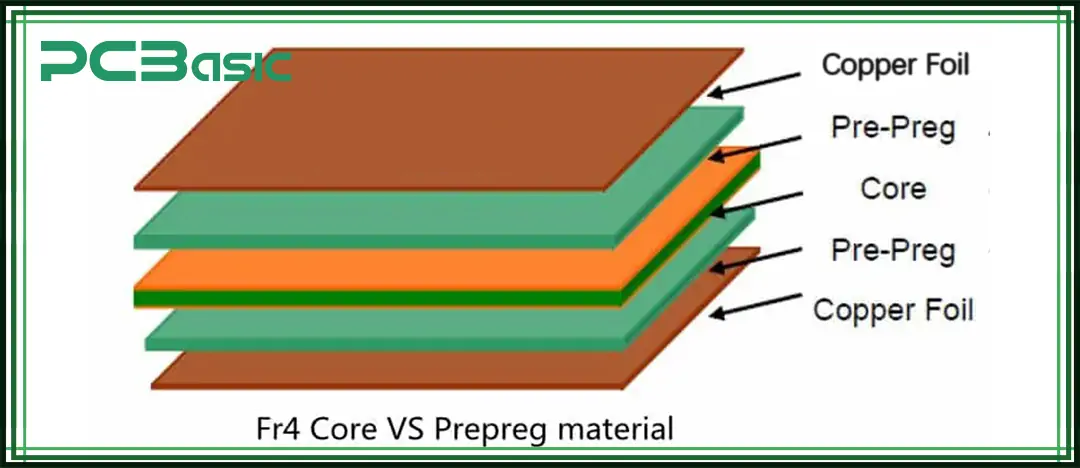

PCB Core is like a finished two-sided circuit board. It's made of fiberglass cloth and fully hardened epoxy, and it's tough, with copper foil on both sides. The core board itself is very stable and can be directly used to process circuit diagrams. In a multilayer PCB, the core board is like the "skeleton" of the entire board, which plays a supporting role and also ensures the strength and electrical performance of the board.

|

Comparison Item |

PCB Core |

Prepreg |

|

Material State |

Fully cured (rigid) |

Semi-cured (soft and tacky) |

|

Composition |

Fiberglass cloth + cured epoxy resin + copper on both sides |

Fiberglass cloth + semi-cured resin (no copper) |

|

Main Function |

Provides structural support and carries circuit layers |

Bonds layers together and provides electrical insulation |

|

Can Be Used Alone |

Yes, can be used as a double-sided PCB or internal layer |

No, must be used with core or copper foil |

|

Can Be Etched for Circuits |

Yes, copper layers can be etched to form circuits |

No, it does not contain copper |

|

Position in PCB |

Core structural layer between other layers |

Adhesive layer between cores or between core and copper foil |

|

Behavior During Lamination |

Remains unchanged under heat and pressure |

Flows and cures under heat and pressure to bond layers |

|

Common Thickness Range |

Thicker (e.g., 0.2mm, 0.4mm, 0.8mm) |

Thinner (e.g., 0.05mm, 0.1mm, 0.15mm) |

|

Conductive |

Yes (via copper layers) |

No (used only for insulation and bonding) |

In general, the PCB core is the hard-core layer that provides structural support and conductive path, while prepreg is the key material that acts as the glue and insulation layer. In modern multilayer PCB manufacturing, one cannot do without the other.

In summary, understanding what PCB prepreg is, its constituent materials, and common types is very basic and important knowledge for those engaged in PCB design or manufacturing. Understanding the role of PCB prepreg will help you make more informed design decisions and build more reliable boards.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.