Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: A PCB Assembly Company in China

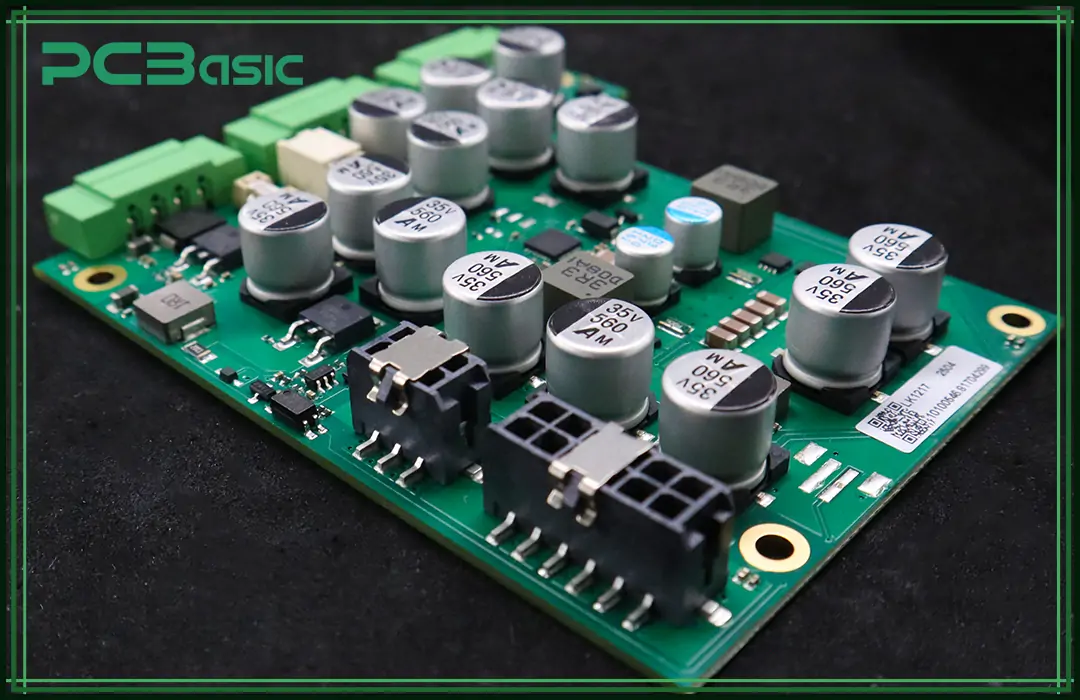

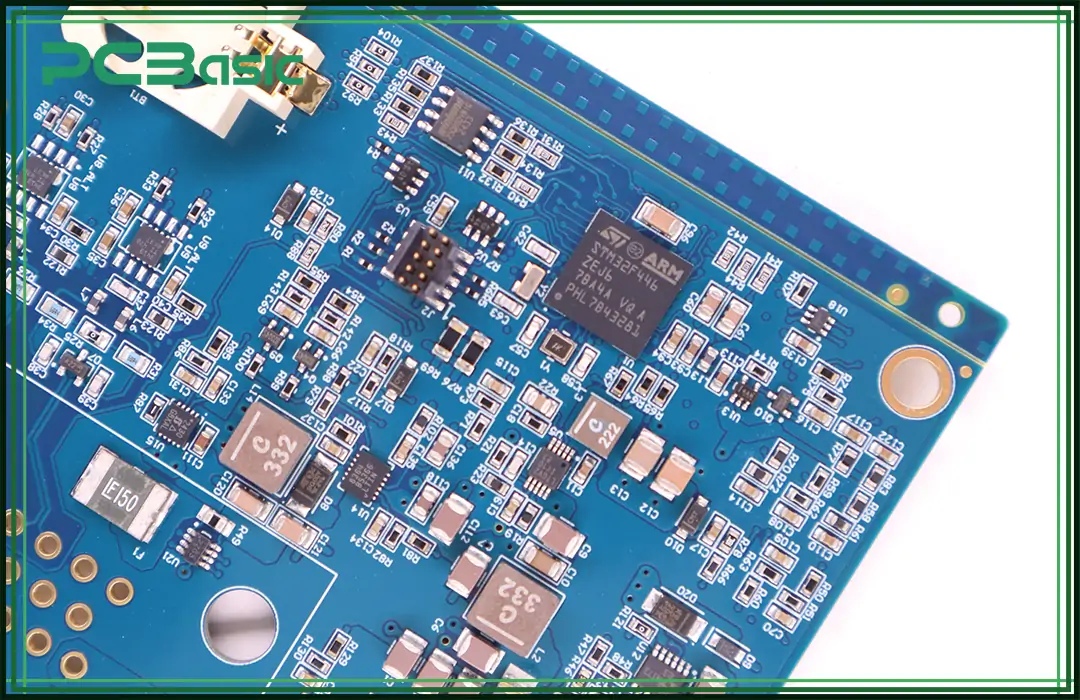

When it comes to reliable circuit board assembly services, selecting the right PCB assembly company is essential. PCBasic stands out among PCB assembly companies in China, providing comprehensive and efficient printed circuit board assembly services tailored to your specific needs.

When it comes to reliable and high-quality PCB assembly services, PCBasic stands out as one of the leading PCB assembly companies in China. Specializing in comprehensive printed circuit board assembly, PCBasic provides a wide range of tailored electronics manufacturing solutions for diverse industries worldwide.

As an experienced PCB assembly company, PCBasic offers complete and customizable solutions, including:

Trust PCBasic, your dependable partner in PCB board assembly—where quality meets reliability every step of the way.

China is renowned for hosting some of the world's top PCB assembly companies, providing comprehensive electronics manufacturing solutions that cater to diverse global needs. When partnering with a Chinese PCB assembly company, you can expect several distinct advantages:

By leveraging these distinctive features, Chinese PCB assembly services have become a trusted choice for global businesses aiming for excellence in electronics manufacturing.

PCB assembly is the process of placing and soldering electronic components onto a printed circuit board to create a fully functional electronic device. This process is crucial because it determines the performance, reliability, and longevity of the final product. Whether it’s a consumer gadget or a cutting-edge industrial application, the success of the device depends on the quality of the PCB assembly.

PCB assembly companies specialize in combining technical expertise, state-of-the-art machinery, and rigorous quality control measures to ensure optimal results.

One of the most efficient solutions offered by PCB assembly companies is turnkey PCB assembly, an end-to-end service that encompasses everything from PCB manufacturing to assembly and final testing.

Use Cases: Turnkey PCB assembly is ideal for a wide range of products, such as smart home devices, wearable technology, and industrial automation systems.

Prototype PCB assembly focuses on creating small batches of PCBs for testing and validation during the development stage.

Why It Matters:

Key Considerations: When choosing a PCB assembly company for prototypes, look for quick turnaround times, precision, and the ability to scale production seamlessly.

Choosing a reputable PCB assembly company like PCBasic ensures quality, efficiency, and reliability in your circuit board assembly projects. Whether you're in need of prototype PCB assembly or full-scale PCBA manufacturing, our electronics assembly services are designed to exceed expectations. Partner with PCBasic, one of China’s leading PCB assembly companies, and experience superior printed circuit assembly solutions today.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.