Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > A Comprehensive Guide to PCB Test Coupons

In the world of electronics manufacturing, ensuring the integrity and quality of printed circuit boards (PCBs) is paramount. One of the most effective methods to validate the quality of a PCB is through the use of test coupons. These are small, specifically designed pieces of PCB that undergo various tests to simulate real-world conditions, ultimately ensuring the performance and reliability of the board.

While PCB coupons are a standard in many industries, their application is particularly important in PCB design and manufacturing. This blog explores the importance of PCB test coupons, their design, and the various tests performed using these small but crucial pieces of circuitry.

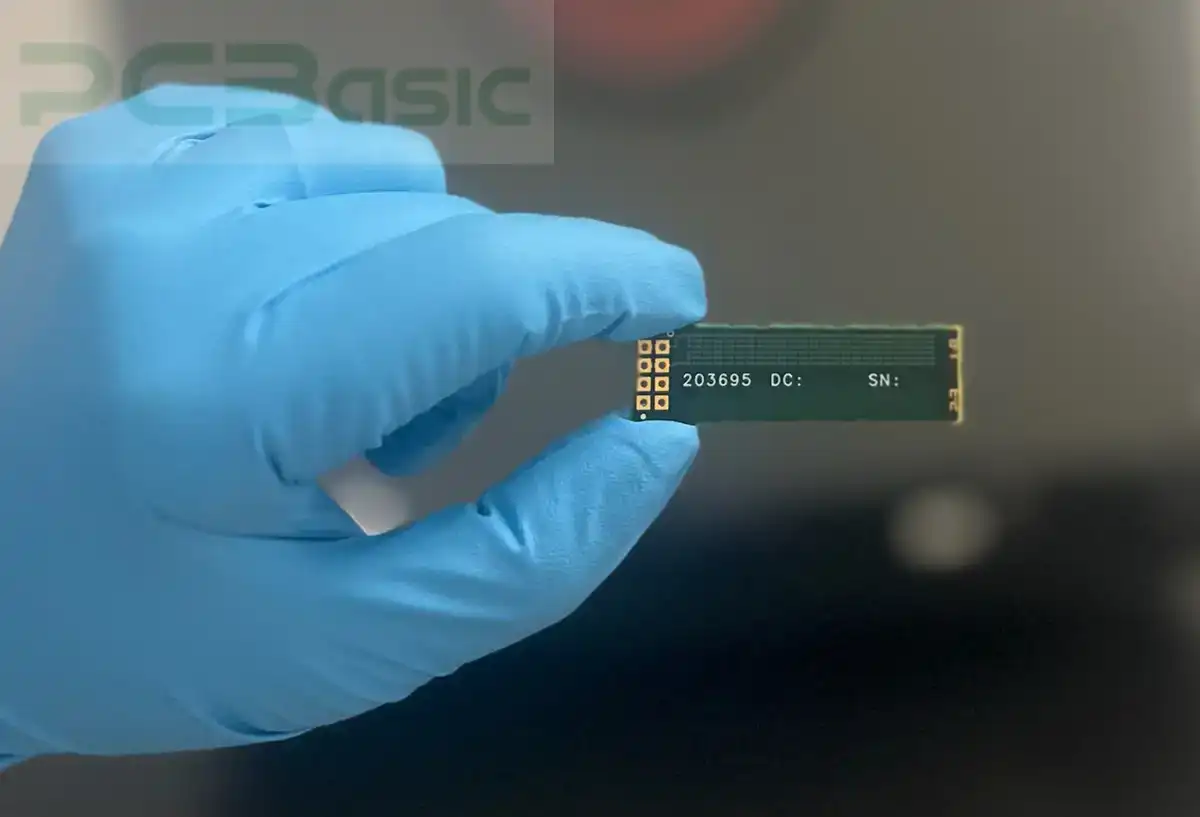

A test coupon is a small, separate piece of a PCB that is incorporated into the design for the purpose of testing and validating various characteristics of the PCB. They serve as a "miniature version" of the full PCB, allowing engineers to perform specific tests without needing to test the entire board. These coupons are used to measure electrical performance, signal integrity, and thermal conditions, as well as to verify manufacturing processes such as soldering and welding.

The ultimate goal of using PCB coupons is to assess the quality of the PCB before mass production or implementation. These test coupons are often included in the initial PCB layout, where they are positioned in areas where electrical or mechanical tests are critical. The data obtained from these coupons can be used to make informed decisions about PCB quality, and even to troubleshoot issues before they affect the larger circuit.

The location of PCB coupons is a critical consideration in the design process. Typically, PCB coupons are placed in areas that are likely to encounter the most significant electrical and thermal stresses. In some cases, PCB coupons are located at edges or corners where variations in manufacturing processes, such as welding or soldering, are most likely to occur.

These coupons are often positioned near components that require rigorous testing, such as vias, traces, and pads that are prone to defects or failures during the assembly phase. The positioning of test coupons can vary based on the specific requirements of the PCB design and the type of tests being performed. For example, in a high-frequency circuit, test coupons might be used to evaluate signal integrity, whereas, in a power distribution system, they might be used to assess thermal management or current carrying capacity.

1. Cost-Effective: PCB coupons are cost-effective because they allow manufacturers to test various aspects of a board without needing to test the entire PCB.

2. Improved Reliability: Using test coupons helps to identify weaknesses early in the production process, ensuring the ultimate reliability of the final product.

3. Efficient Testing: Test coupons enable precise testing of specific areas of the PCB, which helps engineers focus on critical components.

4. Versatility: PCB coupons can be used for a wide variety of tests, such as weld test coupons for verifying solder joint integrity, or metal coupons for thermal cycling tests.

1. Size Constraints: As test coupons are typically small, they may not fully represent the overall behavior of the entire PCB.

2. Testing Variability: The conditions of the coupon tests may not always match the operating conditions of the final product, which could lead to discrepancies in performance.

3. Manual Labor: Depending on the test, performing the necessary evaluations can require considerable manual work and may be subject to human error.

PCB test coupons are used in a variety of testing methods to assess different characteristics of the PCB. Some of the most common tests performed include:

1. Weld Test Coupons: These are specifically designed to test the quality and strength of welded joints on a PCB. This is particularly useful in the evaluation of soldering or welding processes used in the assembly of the board.

2. Electrical Testing: Test coupons are used to check electrical performance, such as signal integrity, resistance, and continuity, to ensure that the PCB will function as intended.

3. Thermal Testing: Metal coupons or weld coupons can be subjected to thermal cycling to assess how the PCB will perform under temperature variations. This is especially important in designs that will experience significant heat stress.

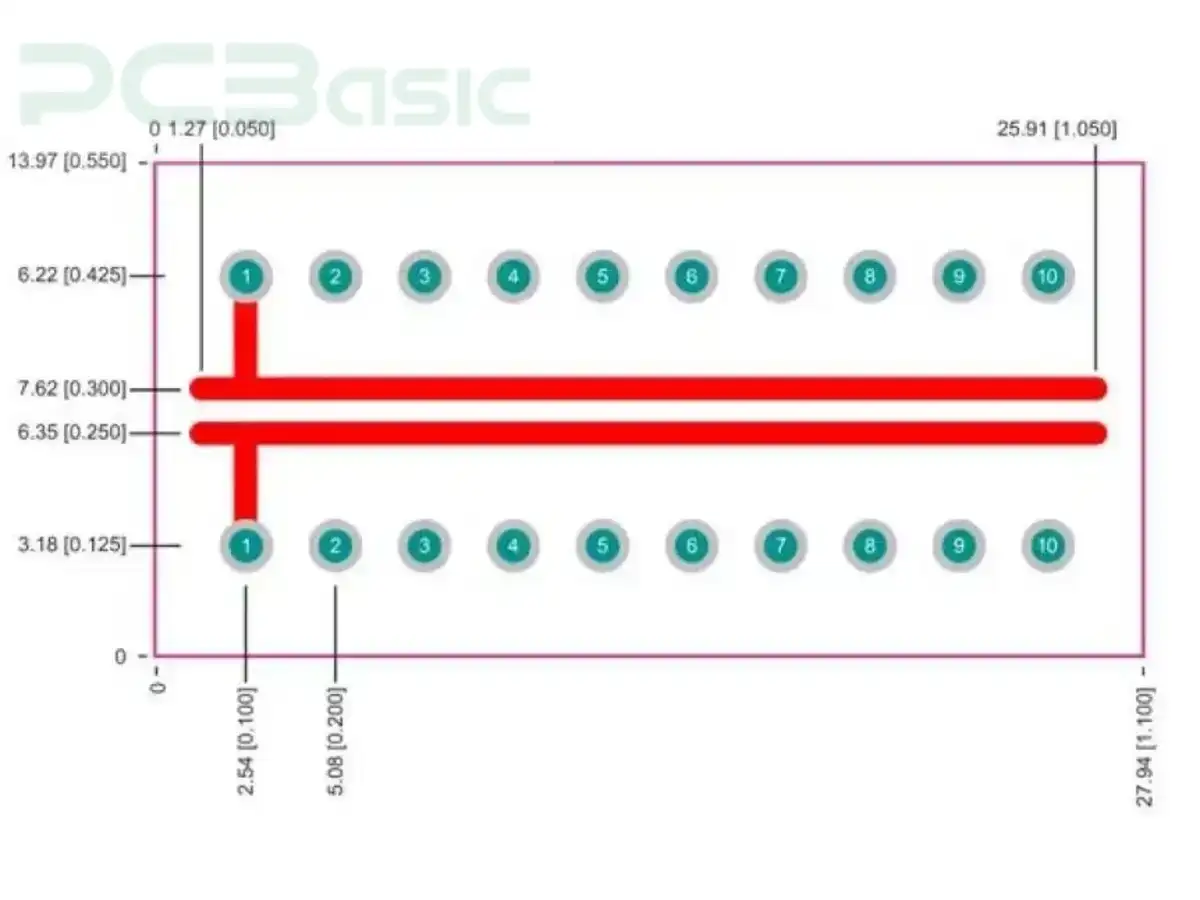

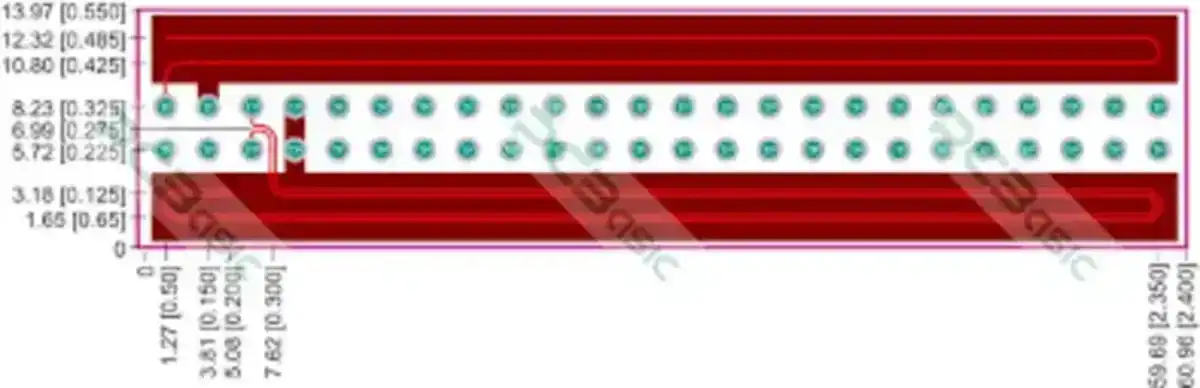

4. Coupon Welding Test Plate Dimensions: In the case of weld coupons, these test plates often come in standardized dimensions to ensure that the test results are reproducible and comparable across different manufacturers and products.

5. Visual Inspection: Test coupons also provide an opportunity for visual inspection, helping to identify any visible defects or irregularities in the PCB's manufacturing process.

6. Mechanical Stress Testing: These tests help to evaluate the mechanical robustness of the PCB, including its ability to withstand physical forces like vibration or flexing.

The design and structure of a PCB test coupon depend on the type of test it is meant to undergo. For example, a weld test coupon might include specific trace patterns designed to replicate the types of solder joints found on the final PCB. These coupons may also include a variety of different features such as pads, vias, and traces that simulate those on the main PCB to ensure consistency in testing.

In many cases, the test coupon is designed to match the general layout of the PCB, but with certain adjustments to enhance the ease of testing. This can include areas where the coupon is more heavily populated with test pads or areas specifically designed for thermal testing, such as larger areas of copper to conduct heat more effectively.

When designing these coupons, the key is to balance between simplicity (for cost efficiency) and complexity (to provide a realistic simulation of the board's characteristics). The goal is always to ensure that the test results from the coupon provide valuable insights into the potential performance of the full PCB.

PCB test coupons are a vital component in the electronics manufacturing process. By allowing engineers to test the performance and quality of specific PCB areas before full-scale production, they help mitigate potential issues and ensure the ultimate reliability of the final product. Whether it's checking the integrity of weld test coupons, verifying the thermal cycling performance of metal coupons, or performing a general electrical test on PCB coupons, these small but essential pieces of PCB design play a critical role in modern electronics testing. As PCB designs continue to evolve, so too will the methods for testing them, making PCB coupons an indispensable part of the development and quality assurance process.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.