Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Low Volume PCB Assembly Services

Low volume PCB assembly services are increasingly favored by various customers in the electronics industry.

Whether it is product prototype verification, small-scale pilot production, or custom production for special applications, low-volume PCB assembly can provide enterprises with flexible and economical solutions. In addition, small-batch PCB assembly services can also be flexibly adjusted according to customer needs, supporting a variety of technologies (such as SMT, THT, and hybrid technology), and a series of quality tests, this efficient and flexible service model provides customers with important technical support and time advantages in a highly competitive market.

Low volume PCB assembly is a printed circuit board assembly service for fewer orders. It usually includes a variety of services such as a small batch of circuit board assemblies, prototyping products, testing phases, or small-scale market trials. Compared with mass production, low volume PCB assembly flexibility is higher. Then, let's take a look at PCBasic, a multi-variety, small-batch ODM and OEM service provider!

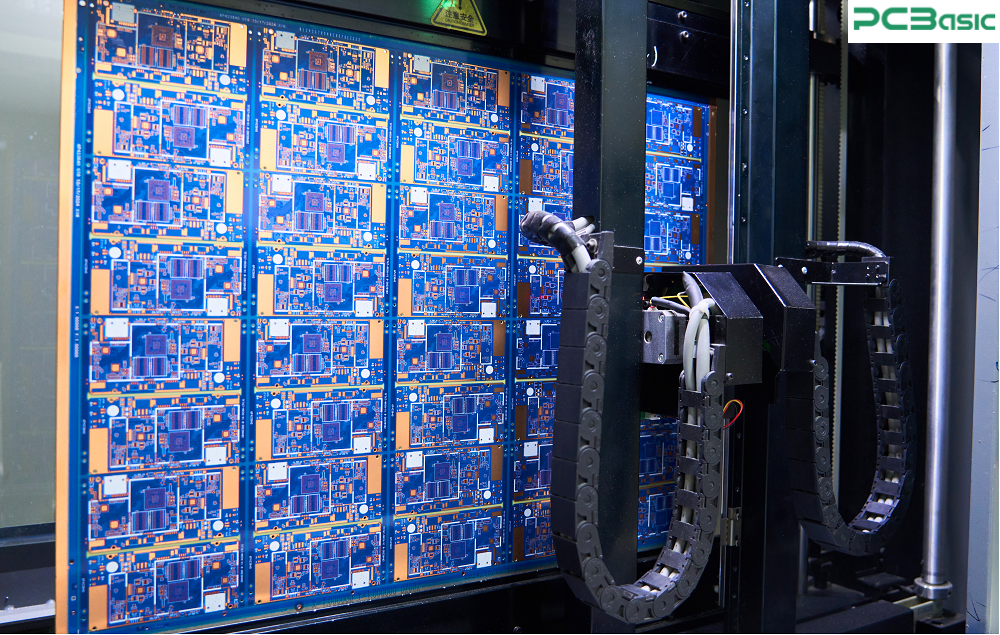

PCBasic is a one-stop ODM and OEM intelligent service manufacturer focusing on multi-variety, small batch/high volume. It has its own factory and advanced equipment, a total of eight SMT lines (2 prototype lines, 2 trial production lines, 4 batch lines), as well as a separate DIP line, self-developed manufacturing execution system, LCR incoming inspection system, SMT fault detection system, sample patch systems, MES systems, intelligent material rack, and advanced intelligent ESD electrostatic protection systems, etc.

PCBasic's core business philosophy is "speed, quality, technology, service". If choose us, you can get more benefits than the following:

• Accelerated Product Development and Reduced Time-to-Market

• Flexible Solutions for a Variety of Industries

• Professional Team Support

• Efficient and Fast Custom Products

• Affordable Solutions

Precision manufacturing: We have a long-term cooperation PCB board factory, and can ensure that every PCB, even low volume products, can meet high-quality standards.

Design for Manufacturing Feasibility (DFM): Optimize the production process, reduce production errors, and control costs (to provide you with the best solution with high quality and low cost).

Support for multiple technologies: Surface mount technology (SMT), DIP, and hybrid design to meet diverse project needs.

Component procurement: We have the original supply chain agent and strategic cooperation big data platform, being able to quickly supply more than 30,000 kinds of components.

Testing and quality assurance: In the production process, we will carry out strict testing and quality control to ensure that products meet the standards.

|

Service Category |

Service Details |

|

Design |

Design for Manufacturing (DFM) analysis to identify and optimize potential manufacturing issues |

|

Component Sourcing |

High-quality component sourcing, flexible to accommodate low-volume orders |

|

Assembly Technology |

Support for Surface Mount Technology (SMT), Through-Hole Technology (THT), DIP, and mixed assembly |

|

Testing and Inspection |

Visual inspection, Automated Optical Inspection (AOI), X-ray inspection, and functional testing (Customizable fixture) |

|

IC Programming |

IC programming services to meet specific functional requirements |

|

Design for Testability (DFT) |

Design test points to optimize the testing process and improve product reliability |

|

Low Volume Prototyping |

Rapid prototyping to support design validation and proof of concept |

|

Quick Response and Flexible Lead Times |

Rush services and flexible production schedules to meet customer needs |

|

Customer Technical Support |

End-to-end technical support, including DFM/DFT recommendations and testing improvements |

PCBasic’s Online Quote Contact PCBasic

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.