Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic's Flying Probe Test Service - Ensuring Your PCB Quality

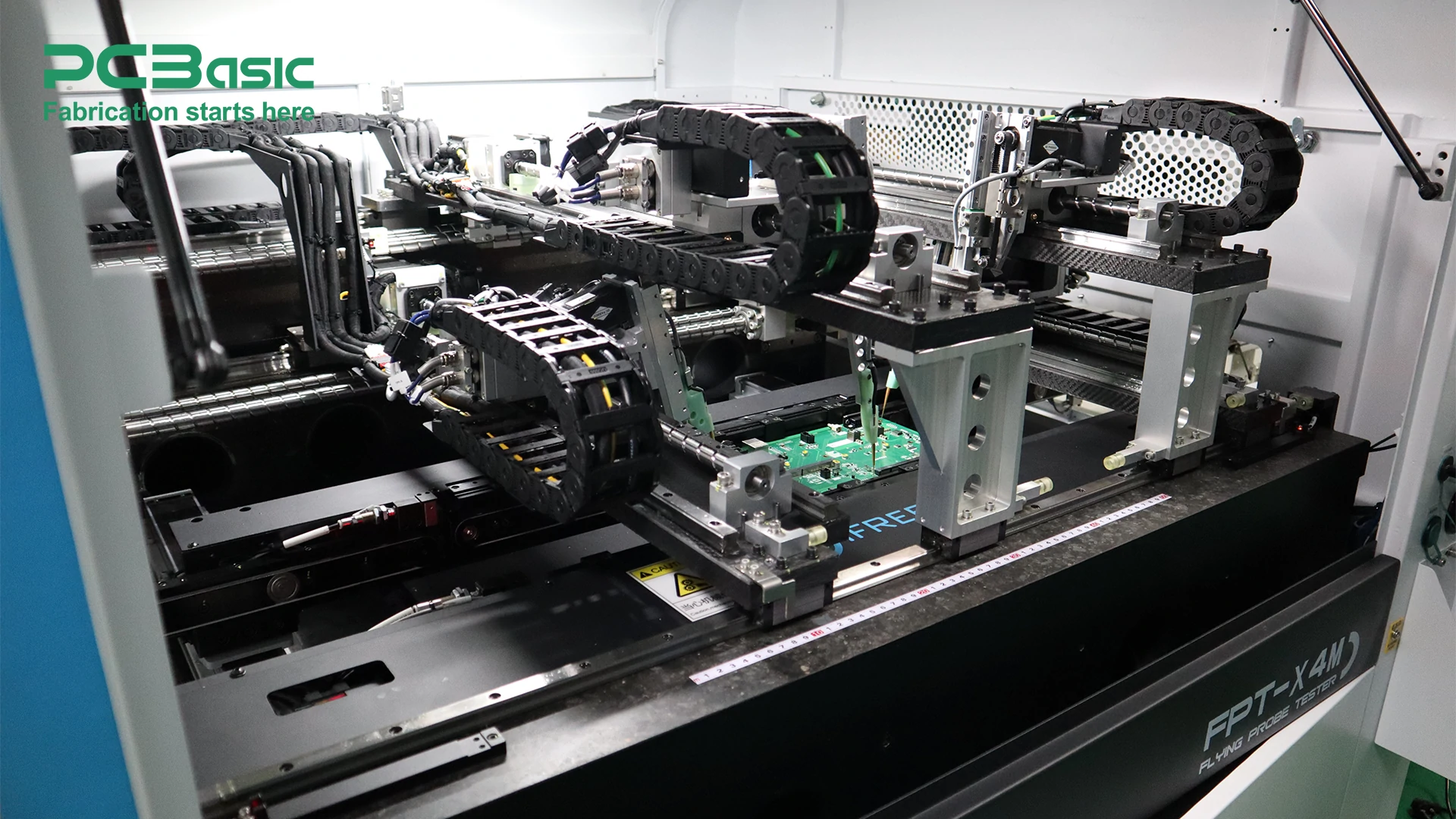

Flying probe testing is often used for detecting short circuit, open circuit, component misalignment and welding problems, is an important method to ensure the quality of PCB assembly. If you are looking for a reliable, trustworthy and accurate testing company, PCBasic will be the ideal choice for you. So why choose PCBasic's flying probe test service? This article gives you the answer, please see the points discussed below.

Due to the complexity of PCB design and production process, PCB testing is faced with many challenges; the following are the main difficulties in PCBA testing:

Modern PCB design often involves high-speed signal transmission and welding of tiny components, which requires test equipment to be able to detect small electrical problems (such as loss of signal integrity, open circuit, short circuit, etc.). However, traditional test methods sometimes cannot meet these high accuracy requirements, so how to improve test accuracy and reliability has become a major pain point for customers.

In the prototyping and low-volume production phase, customers are often under pressure to deliver quickly, and customers need to complete the assembly and testing of PCBS in a short period of time in order to quickly validate the design and get it to market. However, traditional test methods often require custom test fixtures, and the entire test process takes a long time, which affects rapid delivery. In order to cope with rapid iteration and delivery needs, how to shorten the test time and improve production efficiency has become another major challenge for PCB assembly testing.

Every PCB design has unique electrical connectivity and functional needs, especially in customization, low-volume production, or rapid prototyping. Traditional test methods often rely on customized test fixtures, which are often unable to meet the needs of rapid adjustment and change, so how to maintain the flexibility of test methods to ensure that various designs can be efficiently and accurately tested has become a major concern of customers.

Today, the market competition is increasingly fierce, in such an environment PCB assembly test cost control has become an important consideration for customers. Although the high-precision test method can improve the quality of the product, it is often accompanied by high test costs. Therefore, how to provide high-quality testing while reducing unnecessary costs is also a difficult problem that test service providers must solve.

The flying probe tester is equipped with high precision test probes and pogo pins, which not only can quickly and accurately check each test point to ensure a stable electrical connection, but also can meet the high standard of production requirements, solving the customer's high-precision testing needs.

Unlike traditional testing methods, flying probe testing is highly adaptable and can be adapted to a variety of designs. As a result, there is no need to customize test fixtures for each PCB design, saving time, reducing costs, and making the PCB testing process faster and more cost-effective to meet customer delivery times without compromising quality. This flexibility makes our flying probe testing services ideal for prototyping, small series production, and custom PCB designs.

PCBasic’s flying probe testing covers a variety of tests, including short circuit, open circuit, signal integrity, component placement, etc. This comprehensive testing ensures that no potential defects are missed (with the use of the pogo pins and test probes of the flying probe tester, the smallest and most complex components even can be detected), providing PCB testing to the highest standards.

Compared to traditional test methods, flying probe testing does not require custom fixtures, reduce manual intervention in the process and optimize the cost structure, which is very suitable for small batch and custom production.

|

Aspect |

Traditional Testing Methods |

Flying Probe Testing |

|

Test Fixture Requirement |

Requires custom test fixtures, time-consuming. |

No custom fixtures needed, saves time and labor. |

|

Setup Time |

Longer setup time due to custom fixture creation. |

Shorter setup time, quick adaptation to designs. |

|

Test Accuracy |

Limited precision, may miss defects in complex designs. |

High precision, thorough testing of all points. |

|

Adaptability |

Needs new fixtures for custom designs. |

Highly adaptable to various designs and volumes. |

|

Cost |

Higher due to custom fixtures and labor. |

More cost-effective, especially for small batches. |

|

Complex Design Testing |

May miss issues in complex or fine-pitch designs. |

Excellent for complex, high-frequency designs. |

With its high precision, flexibility and comprehensive testing, flying probe testing services ensure that your PCB meets the highest quality standards. PCBasic introduced the flying probe tester and put it into production, in order to be able to provide customers with the highest quality PCB assembly test, the fastest, most accurate and most cost-effective solution. If you are looking for a reliable PCB assembly and testing partner, PCBasic is your ideal choice. Our flying probe testing services will help you ensure that your products meet the high requirements of the modern electronics industry. Welcome to contact us!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.