Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is LDR (Light Dependent Resistor)?

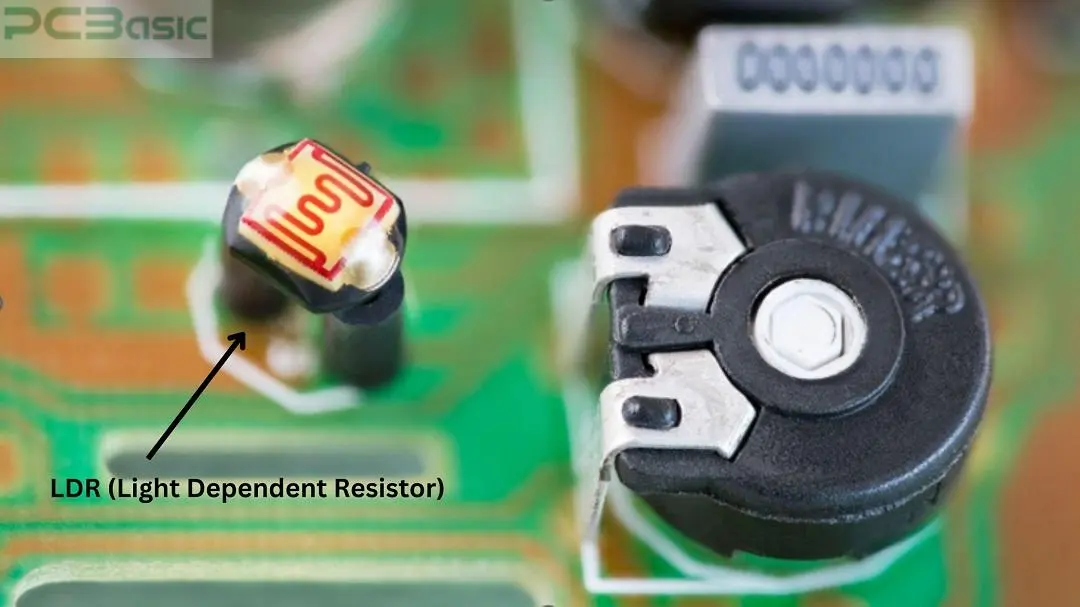

Light Dependent Resistors (LDRs) stand again as anointed photoresistors. They are electronic components whose resistance depends directly on how much light they are exposed to. The LDR's resistance goes down with a rise in light levels and increases with a decrease in light levels. This functionality makes them highly useful in applications that depend on light detection. For example, we use them in streetlights, which automatically glow when it is dusk, and they are also an essential part of light-sensitive modern devices.

It is then crucial for the PCB manufacturers to understand what role LDRs play. They enable designers to make simpler designs more efficiently than light-controlled systems. LDRs might just come in handy to help you improve your circuits as you design automatic lighting systems such as a camera, a light metre, or an alarm system.

Here, we will learn what LDRs are, what they look like, their types, their work, and where they are used. You will be well equipped with the knowledge to apply it in your projects and why they are essential in modern electronics.

An LDR, a photoresistor, is a passive electronic component whose resistance varies with the intensity of light falling on the element. The resistance is high in darkness or low light, whereas the resistance drops to a meager value in bright sunlight. It makes LDRs suitable for circuits requiring sensing or controlling based on light levels.

You would find them in the most common applications, such as automatic streetlights or light-activated alarms. What is an LDR? That is simply a resistor whose behaviour depends on the light intensity surrounding it, which is crucial in light-sensitive applications.

The circuit diagram resorts to an inverted rectangle shape of a resistor with two arrows toward it. It is the light that shines on that component. It will do almost everywhere except that it will differ slightly from country to country. In this regard, for instance, the orientation or angle of some arrows in those diagrams might be different in other countries. This symbol makes it very easy to identify the LDR in any light-dependent circuit, and thus, it forms part of most automated systems.

An LDR sensor is made of a semiconductor material called cadmium sulphide, CdS. This forms the central point of the LDR since it is photosensitive. It is laid zigzag or spiral between two contacts, which can usually be made conductive. The resistance lowers upon falling light on the semiconductor, resulting in more current flows in the circuit.

The outer shell is sometimes translucent and may refract the inner parts to let light pass through to the photoresistor. Thus, a very simple design makes LDRs work quite well in applications like automatic lighting, photography, or sensing through light.

Typically, the selection of an appropriate LDR for a specific circuit entails familiarity with photodiode or, more broadly, photoresistor characteristics. Two significant parameters are resistance across the range of several hundred ohms in bright illumination to several megaohms in complete darkness and generally low power ratings because of the desire for LDRs often to be used in low-power circuits. That also means response time, or how fast it will react to a change in light intensity. Spectral sensitivity describes the wavelengths the LDR can sense, making its use dependent on the lighting conditions.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

LDRs or photoresistors are classified into two types: intrinsic and extrinsic.

Intrinsic LDR are prepared from pure semiconductor materials. These materials have almost negligible conductivity but can be more conductive due to their pure semiconductor nature. In an intrinsic LDR, the electrons get excited from the valence band to the conduction band. It is due to light falling on them, thereby decreasing the resistance.

The intrinsic photoresistors are used where the spectral range of sensitivity is very high. It is sensitive to the visible light spectrum and is used where very light-sensitive devices are required. Typical applications include light meters and measuring devices for solar energy.

Extrinsic photoresistors have been doped with impurities to make the sensitivity possible up to a special wavelength of light. Of the several materials used in such a type of LDR, cadmium sulphide and cadmium selenide have been the most widely used. Impurity doping increases the resistors' sensitivity to higher wavelength light, even infrared. Extrinsic LDRs have been used in most special applications, such as infrared detectors, night vision systems, and flame detection.

Although there are two kinds of LDRs, the advantages are application-dependent. Intrinsic photoresistors are more applicable to general light-sensing applications, while extrinsic photoresistors have applications in specific lighting environments that are illuminated by a non-visible source.

An LDR is based on the principle that it alters with the change in light intensity. Simplifying, an LDR is a photoresistor whose resistance varies inversely to light intensity.

· In the absence of quite a lot of light, the material of the LDR-cadmium sulphide has fewer free electrons, thereby resulting in high resistance.

· In LDR, light falling causes photons to collide with the electrons within that material through energy transfer.

· It excites the energy to the electrons so that they jump to the conduction band from the valence band, thus increasing the number of free electrons.

· Free electrons are much less resistive; this is the other reason why more current flows are needed, as free-moving electrons favor this.

This photoelectric effect causes an increase in the number of charge carriers, which is caused by the exposure of light to LDR material. The stronger the illumination,

· It absorbs more photons. It emits more electrons.

· Resistance drops further and allows more current to flow.

LDRs are used extensively in light-dependent applications.

· Streetlights now automatically turn on at night with the automation of lighting systems.

· Camera exposure meters: Light intensity makes exposure accurate.

· Photosensitive security and alarm systems.

LDRs are very basic in the control circuits of the system requiring ambient light conditions, as they change with resistance according to light.

LDR works in conjunction with their action on the wavelength of light. LDR's resistance varies with wavelengths ranging from ultraviolet to infrared. The best operation of LDR is obtained by visible light within the ranges of frequencies of the material used. The LDR containing cadmium sulfide is the most sensitive along the visible spectrum.

Therefore, they are best suited for these applications where the human visual response becomes a reference point. Such circuit designs require knowing the specific frequency response of the LDRs about the type of light involved if control is to be good.

These LDRs respond to some variation in light intensity or, one could say, some latency until that light shift manifests itself into the associated resistance. It could be too long and annoying in certain situations, especially when shifting from a dark room to highly illuminated daylight.

It is measured in milliseconds and depends on the material of the LDR and its intensity. Therefore, its latency would be considered by designers when using it for applications such as alarms or exposure systems for cameras, for example, requiring a response in real-time by a light source.

LDRs have tremendous practical merits that make them suitable for various applications. This is largely due to the affordability of LDRs, as the materials used to manufacture them are relatively inexpensive. Integration of LDRs in any circuit is as simple as it gets, requiring minimal additional parts; hence, the design is as straightforward as possible.

LDRs usually come from consumer electronics to heavy industrial equipment and are easily adapted to light detection under virtually all conditions. They are mainly used for applications in automatic lighting controls, night light, and exposure control in cameras due to their extreme sensitivity to light levels.

All these remain cost-effective, easy to handle, and highly applicable. They all explain why LDRs remain in use for light-sensing applications.

Even though LDRs have quite several advantages, they do possess a few limitations. These are comparatively slow response devices; hence, their performance is degraded for rapid changes in light. They are sensitive to temperatures; the change in resistance without applying the light makes the circuit design somewhat complicated. It's not the best suited for high-precision measurement as its sensitivity to light is pretty broad.

These factors make them not too practical in high-performance operations, where accuracy and speed are much more than an issue.

These sensors have a range of applications, mainly through the detection of ambient light levels and the corresponding alteration of the electrical circuit. Its application in automatic street light systems, allowing the lights to come operational during dusk and be off during dawn, makes LDRs one of the most common uses. It is also currently applied in camera systems to control exposure, and the camera can automatically change settings based on the increase in the light intensity of the surroundings.

In addition, LDRs are constituent parts of photoreceptors for alarms, clocks, and dimmer switches. In industry, it is applied to measure the light quantity that passes through agricultural greenhouses. It is applied to control automatically operated window blinds, thus providing evidence of their pragmatic application in diverse disciplines.

Many applications of LDRs can easily be used for broad, simple circuit designs, such as a light-sensitive switch or change-of-state relay that switches devices on and off according to the ambient light conditions in the surrounding environment. Other applications would be in a voltage divider circuit where an LDR would adjust the output voltage according to the ambient light conditions.

A harder application is multiplexing a few LDRs with operational amplifiers to control light-dependent systems such as auto fans or light intensity meters. Such circuits do little more than demonstrate the potential of LDR use in a large number of electronic systems.

The very basic function of the LDR, or photoresistor, is its ability to increase its resistance and consequently decrease conductivity due to the change in light intensity. Because of this, when photons strike the material, these are absorbed and raise some of the electrons into the conduction band, thus lowering the circuit's resistance.

LDR acts like a higher resistor in darkness because there is no available energy of light to begin those electrons. It has a linear variation of resistance for light intensities; hence, LDRs are vastly suitable for such applications as variable light control.

LDR in a circuit acts like a variable resistor wherein it varies the amount of current flow based on the sensed light. Its mechanism is simple and efficient, so it's used in devices such as automatic lighting circuits to as complex as light sensors in cameras. An increase in resistance of an LDR then translates into corresponding varying voltage signals, which may be further processed to drive other devices.

A Light Dependent Resistor (LDR) sensor is a device that is able to distinguish light intensity through a sensor. Its resistance reduces within fair light conditions, making it easily possible to measure the light variation around it.

LDR sensors are used in automatic lighting, light-sensitive alarms and brightness control where the light levels must be detected.

The LDR symbol is a rectangle representing a resistor, with two arrows pointing towards it, indicating that light is falling on the component.

LDRs passively change resistance when light falls on them, whereas photodiodes go on to generate current actively. The speed and resolution of LDRs are much slower and less accurate than photodiodes, which give a fast response to changes in light intensity.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.