Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Understanding Electronics Contract Manufacturing: A Complete Guide by PCBasic

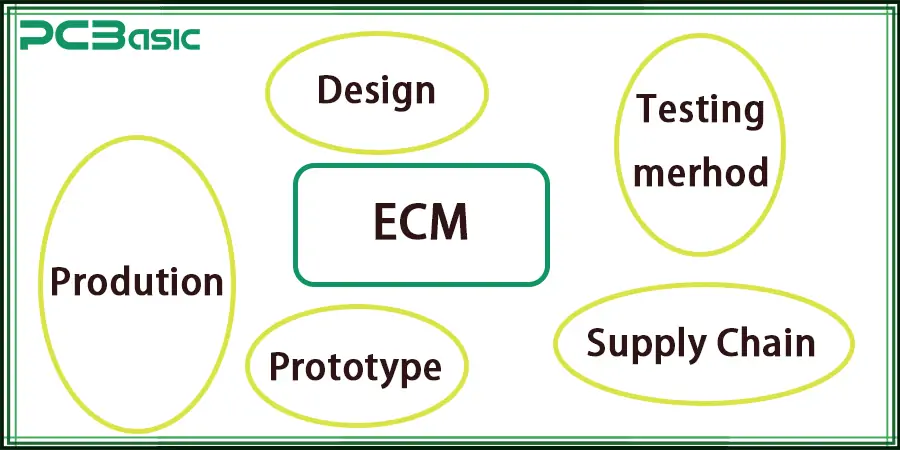

ECM, or Electronic Contract Manufacturing, is defined as outsourcing PCB boards, assembly processes, circuits, electronic components, and products of any particular manufacturer. ECM helps different manufacturers provide their services and products with the latest skills and instruments. From startups to global OEMs, a large number of companies are relying on contract electronics manufacturing to meet flexible production demands. Especially in consumer electronics, high-end customized equipment and industrial-grade electronics contract manufacturing, its performance is particularly outstanding.

In this article, we will comprehensively explain the definition, advantages, types and application scenarios of electronics contract manufacturing services, and introduce you to a leading and suitable manufacturing partner.

The electronics contract manufacturing process is a single solution for the different processes since it comes with circuit designing, creation of PCB layout, component sourcing, board manufacturing, PCB assembly, and final delivery to customers. For all these processes, customers just have to provide the parameters that they need for the final product. It can also involve customers having designed features of their products and then hiring electronic manufacturers for board manufacturing and final assembly.

Electronics contract manufacturing also comes with design from one manufacturer, assembly from another, and after-sales services from third-party contract manufacturers.

Unlike traditional self-built production lines, ECM enables enterprises to leverage the economies of scale and professional manufacturing capabilities of suppliers to enhance production efficiency. In application scenarios with high requirements for quality and stability, such as industrial electronics contract manufacturing, ECM is particularly important. Many enterprises will also entrust contract electronic assembly services to complete complex process links such as SMT surface mount and through-hole soldering.

At present, the market of electronics contract manufacturing services is experiencing explosive growth. Its main driving force comes from the continuous expansion in fields such as consumer electronics, automotive electronics, medical devices, telecommunications and industrial automation. According to the latest market research data, the global electronic manufacturing services (EMS) market is expected to exceed 750 billion US dollars by 2030. The Asia-Pacific region, especially China and India, will become the main growth points for electronic manufacturing services. Trends in the electronic Contract manufacturing market will be:

The rise of high-mix and small-batch production

The manufacturing base in India has emerged

Technology drives the transformation of intelligent manufacturing

The demand for industrial-grade applications is on the rise

As the complexity of electronic products continues to increase, enterprises' reliance on electronic manufacturing services companies that have the capabilities of rapid response and high reliability is also deepening.

Cost savings and efficiency

Outsourcing manufacturing helps different electronic manufacturers save their high costs for instruments, getting skilled labor services and other features. Through ECM, larger bulk manufacturing is made, which also helps to reduce the overall cost and single component cost. It also provides high-speed production by using the latest machines and skilled staff and reduces the extra wastage of materials.

Flexibility

There is no need for the high value of cost for scaling the manufacturing up and down according to product demands for customers and market trends. The business can be pivoted by adapting new techniques and using new products and matters with the application of innovative designs. Any manufacturer can provide larger services without using new learning methods and services.

Focus on Core Competencies

Outsourcing helps any business or manufacturer apply their resources for research, product development, marketing techniques, and providing different services to users. The partnership with special and expert manufacturers helps businesses enhance their skills and technologies. So in a short time of manufacturing, they are highly invested in new ideas and starting new initiatives.

PCB Assembly (PCBA)

The PCBA or PCB assembly involves the connection of different types of components on the PCB board and makes a complete finished board. There are two methods used for the connection of components on PCB boards to make working devices: SMT and the through-hole assembly process.

SMT is an assembly technique that helps to connect components on the board surface, and through-hole involves drilling holes on the board surface, and component leads pass through those holes to make connections.

Complete product assembly

In this type of ECM service, the complete manufacturing process of the board is performed, such as from the sourcing of components to the final board assembly with the complete requirements of the board. This service board is completely assembled and ready for delivery to customers.

High-quality and low-volume production

In this service, the client's demands for low-volume production but with high quality are provided. This service is helpful for businesses that are providing services or products for certain niches that need proper customization.

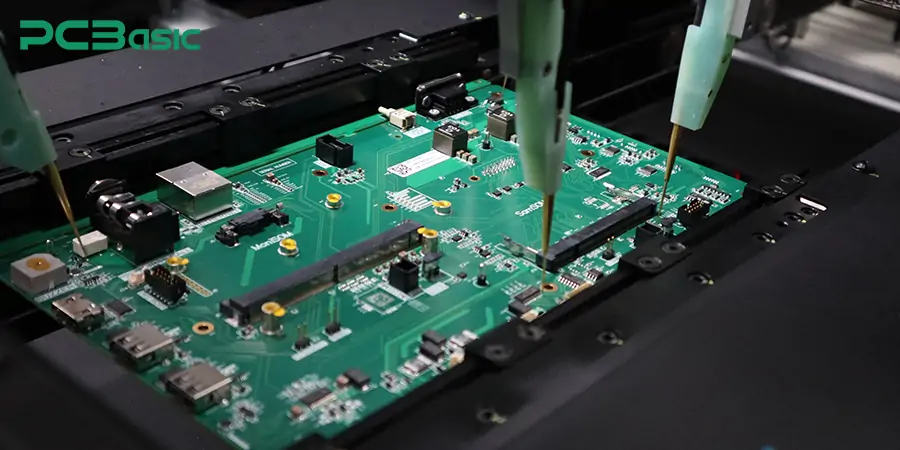

Testing and quality control

In this ECM, complete testing from start to end is performed to make errorless boards and devices according to the demands of customers. Different types of tests are performed, such as functional tests, reliability testing and compliance tests, that make products error-free and ready to use.

Customers Engagement

ECM started with getting the details of customers' products, such as the features and volumes provided to electronic manufacturers.

Components Sourcing

In this step, components required for customers' products and according to requirements are sourced with high quality and low cost.

Manufacturing plan

Electronic manufacturers provide complete manufacturing plans from the start to the end of products to clients with the process used.

PCB Assembly

SMT and through holes processed are used to connect components on the PCB board and make the complete board assembly.

Final Assembly

Now, the final assembly of products is made, and all components are assembled on board in casing with working conditions.

Testing and Delivery

Now final testing is performed on devices to check they are working, and after making sure that every test is passed, the device is delivered to the customers. And For any inspection or modification, customer support is provided.

Medical

Different medical OEMs get services from ECM manufacturers that help them provide quality processes with the required standards. With that, they provide them with industrial expertise that teaches them complete product development.

Industrial Uses

Many industries use ECM services to create prototypes of their products and perform different tests to get new products for the market and users.

Aerospace

The instruments used in aviation and military needed certain materials and features that helped them to operate in hard conditions. ECM helps to get services from such manufacturers that have quality products with proper modifications and advancements.

Telecommunications

The components and devices used for telecom sectors and communication devices need high performance and scalability to fulfill the demand for new and latest connections that are getting through ECM.

ECM defines a company or manufacturer with contract manufacturing services. It makes products whose designs are created by another manufacturer. Services included for ECM are PCBA, component sourcing, different types of testing, etc.

EMS included more extensive manufacturing services for electronic components and different assembly processes. EMS service providers can handle various services, including PCB assemblies, such as design, manufacturing of the board, engineering, assembly, and testing. They provide services from start to end.

|

Dimension |

ECM (Electronics Contract Manufacturing) |

EMS (Electronics Manufacturing Services) |

|

Definition |

Companies that provide contract manufacturing services are usually based on customer designs. |

Companies that offer integrated electronics manufacturing services from design to production. |

|

Scope of Services |

- PCB Assembly (PCBA) - Component sourcing - Functional and electrical testing |

- PCB design and engineering - PCB fabrication - Component sourcing - PCB assembly and testing - Final product assembly and delivery |

|

Design Capability |

Customer provides the design; ECM is responsible only for manufacturing. |

EMS can participate in product development, offering design input, optimization, and engineering support. |

|

Manufacturing Depth |

Mainly focuses on product assembly and contract production. |

Provides a complete process from initial design, prototyping, manufacturing, testing, packaging to shipping. |

|

Typical Clients |

Brand owners and OEMs looking to outsource parts of the production process. |

Startups to large OEMs, especially those needing fast time-to-market and end-to-end service. |

|

Service Objectives |

Reduce manufacturing costs and simplify procurement. |

Improve production efficiency, shorten time-to-market, and deliver end-to-end manufacturing solutions. |

|

Applicable Industries |

Mainly standardized products such as consumer electronics, home appliances, and lighting. |

Industries with higher demands for quality and efficiency, such as medical, automotive, aerospace, and industrial automation. |

|

Capability Positioning |

More focused on manufacturing and production; usually not involved in the design stage. |

Offers more comprehensive services, with high-end manufacturing and system integration capabilities. |

PCBasic is a company that provides different services to its clients all over the world. PCBasic works as an electronic manufacturing service provider for PCB and small to large-level PCBA services, offering PCB design and manufacturing on a single platform. It is equipped with the latest machines and skilled staff to provide quality services for different manufacturing of devices, from prototypes to final assembly. And it offers research and development solutions and material selection for OEM production and also has self-development systems such as CRM, MES, ERPT, etc. Its main services include:

Full-process services: covering PCB assembly (PCBA), component procurement, functional testing, system integration, etc

Customized support: Supports flexible production from small batches to large batches, and is widely used in industries such as manufacturing, consumer electronics, and medical care

Engineering support: Provide DFM manufacturability design review, optimize production processes, shorten delivery times, and reduce costs

PCB Assembly (PCBA) - Surface Mount Technology (SMT), Through-hole Technology (THT), and hybrid technologies

Component Sourcing - Cooperate with global authorized distributors to ensure the quality of parts

Testing and Inspection - AOI automatic optical inspection, X-ray, ICT online testing and functional testing

Box Build Assembly - Wiring harness processing, shell installation, final packaging and shipment

In addition, PCBasic has internationally certified quality standards and quality assurance.

PCBasic is committed to providing customers with high-quality electronic manufacturing services that meet international standards:

ISO 9001:2015 - Quality Management System Certification

ISO 13485 - Compliance Standard for the Manufacturing of Medical Devices

IATF 16949 - Quality Standard for the Automotive Electronics Industry

RoHS and REACH compliance - Environmentally friendly production processes

The quality control process of PCBasic is strict, and the production documents are traceable, which can ensure that every product meets the customer's specifications. Are you looking for a reliable electronic contract manufacturing partner? PCBasic can provide professional end-to-end contract electronic manufacturing services, meeting your full-process needs from sample making to mass production. Visit our website, www.pcbasic.com, to learn more about our capabilities to help you get to market faster.

ECM is a high-speed process providing flexible solutions for high-speed services from skilled electronic manufacturers. In this service, you can get your products from the prototype level to the advanced level. ECM involves the sources of the components, assembly testing, and final assembly with delivery to customers. With the use of these services, you can get quality products from experts and reliable manufacturers. ECM services are beneficial in terms of making high-quality products as compared to your competitors.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.