Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is Box Build Assembly?|PCB Box Build Assembly Services

Many industries rely on product box builds or system integrations, including those that deal with consumer electronics like computer hardware, game consoles, and audio equipment. Box build assembly is also essential for telecommunication devices like routers, modems, and switches.

In industrial settings, the technology helps manufacture motor drives, automation controls, and power supplies such as AC-DC and DC-DC converters. The automotive PCB sector also benefits from box build assembly as it's integral to manufacturing navigation systems and EV charging stations. With box builds, the medical sector benefits from medical devices like imaging equipment, monitoring machines, and analyzers. On the other hand, the vending sector relies on box builds for vending machines, ticketing, and self-checkouts. Each day, the need for box builds rises, and so are electronic manufacturing services (EMSs) to offer the service. The question, however, is, why do you need a box-build assembly manufacturing expert? What happens during a typical box build assembly process? And more importantly, how do you choose the correct box build assembly services?

This guide shall answer the three concerns. But first, let's understand what box build assembly is!

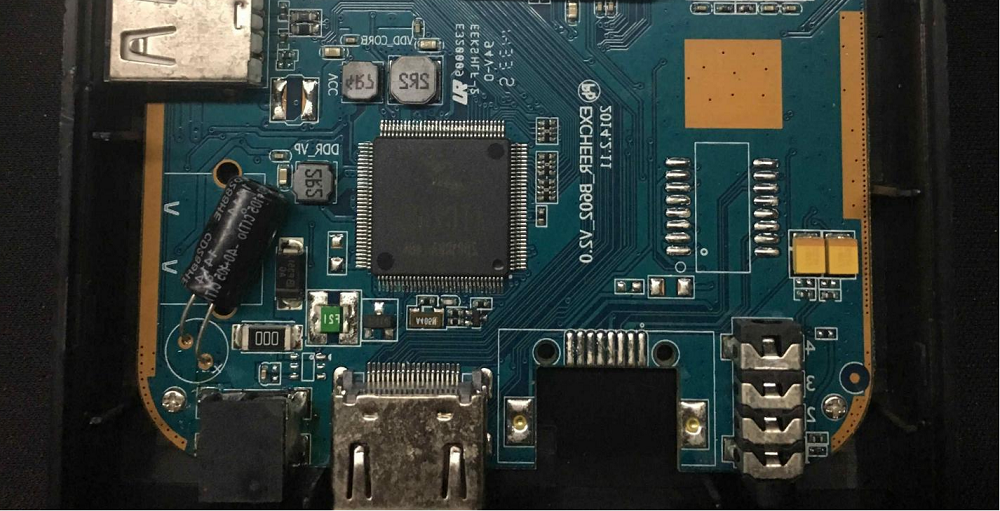

Box build assembly (sometimes called box build) is the process of putting electronic components, parts, and subsystems into a box-like container or an integrated system. The assembly process is a ubiquitous process of electronics, automotive, aerospace, telecommunication, and medical product manufacturing industries.

Box build is a detailed system integration and assembly process that involves these seven key stages:

Kitting involves organizing all the essentials necessary for a streamlined production process. The assembly process ensures that all needed supplies are available before the assembly begins. That includes PCBs, enclosures, cables, screws, and other fasteners, and accessories like keypads and sensors.

Kitting generally involves these best practices:

· Parts classification

· Defining maximum and minimum levels for all part categories

· Using sales forecasts and historical data to predict future demands

· Lead-time tracking

· Barcoding (using barcoded labels to track the components)

· Automated planning of materials using ERP and MRP technological solutions

It's crucial to have timely access to quality components during box build assembly, and that's where supply chain management comes in. Effective supply chain management involves:

· Correct vendor selecting

· Dual sourcing (which is finding alternate suppliers)

· Supplier localization

· Inventory planning

· Timely order placement

· Logistics optimization

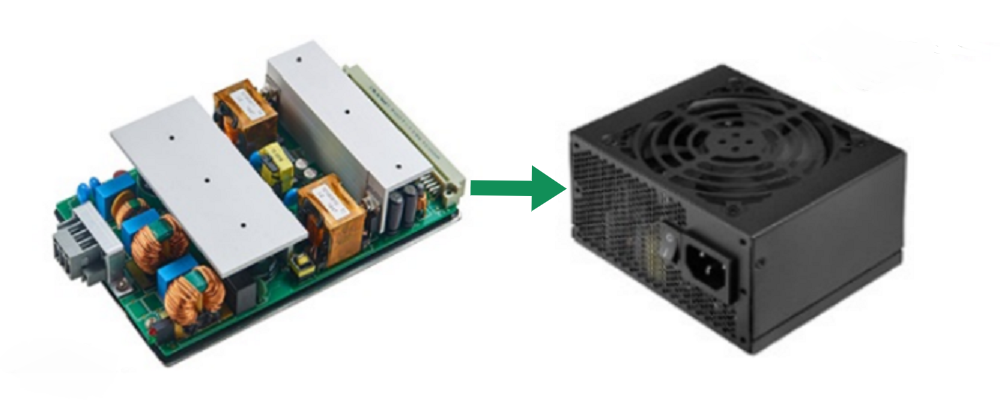

Component assembly involves building smaller modules and sub-parts of the main product before final integration. Such components include wire harnesses, i/o panels, motor drives, and power supplies like AC-DC converters.

After building up the modules and sub-parts of the main product, the next phase involves putting them together into one large assembly. It includes mounting PCBs and interconnecting them with wire harnesses and cables. However, issues like sufficient mount connectors, thermal design, and wire spacing are essential considerations at this box-build assembly stage.

The integration phase ensures that all parts combine into a cohesive product ready for use by the end user. It involves adding keypads, switches, mounting plates, knobs, displays, and many other individual components to the enclosure.

The integration phase also involves adding branding elements like badges, logos, decals, and graphics. Furthermore, the box-build assembly team adds warning labels, compliance signs, and agency seals at this stage.

Before the end user can access the final product, the box build assembly manufacturer must test it and ensure it passes all quality checks. That includes the following:

· Functional testing – which involves key function verification, operation limit testing, switches and buttons tests, and electrical safety testing

· Compliance and safety testing – which involves safety standards like CSA, CE, UL, and CCC, as well as environmental compliances

· Product test – which involves visual inspections, thermal testing, acoustic testing, calibration testing, and burn-in testing of the product

In addition, the product has to undergo final tests, which involve debugging and correcting faults. This comprehensive examination ensures that the final product meets the crucial safety, reliability, and quality control metrics.

Once a box build assembly product passes the testing and quality checks, it goes through the packaging and logistics phase, making it ready for delivery. This seventh step involves final touches such as packaging, applying protective film to delicate areas, and bubble wrapping. It also involves inserting product manuals, registration papers, and warranty cards and adding accessories like power cables, CDs, and brackets.

Partnering with a box build assembly manufacturer is best for your business for these reasons:

a) Faster time-to-market

A professional box-build assembly company proficiently shortens the time between the product conception and its market delivery. They successfully hasten the time-to-market (TTM) by starting production with available box-build assembly lines, leveraging proven production systems and processes, and establishing solid supply chains.

b) More focus on core competencies

During a professional box-build assembly arrangement, original equipment manufacturers (OEMs) and brands channel their energy and focus their resources on core competencies like software development, product design, and marketing. They then delegate the manufacturing to contract manufacturers, saving time and resources.

c) Cost saving

Working with expert EMS providers minimizes costs through economies of scale, ensuring competitive pricing for your products. They can apply that knowledge to the box-build assembly services to save on production and component procurement costs. Established EMS promise minimal inventory costs and save on shipping costs (through consolidated logistics). Moreover, by focusing on core competencies, they only redirect their financial muscles to high-value areas.

d) Quality and reliability

Expert PCB box build assembly services enjoy reliable testing and quality control checks, ensuring the final product meets the industrial requirements. These companies also promise quality and reliability by working in certified facilities, hiring highly skilled technicians, and utilizing high-precision equipment.

Furthermore, they automate most processes and are in charge of component sourcing to avoid counterfeits, and that improves their reliability scores.

e) Flexibility and scalability

Expert box-build assembly services providers understand what it takes to scale up or down production depending on the market. They adapt quickly to sharp market shortages and demands. Their flexibility is evident through their modular and multiproduct assembly lines, Just-in-Time (JIT) sourcing, rapid changeovers, and availability of temporary workers during peak seasons.

f) One-stop-shop services

Box-build assembly manufacturers handle everything from components sourcing and sub-assembly to final assembly, quality checks, and logistics. They offer a one-stop shop for all these services, which is convenient for you.

While numerous PCB box build assembly manufacturers exist, you can quickly narrow your options and settle on the best. Below are the key considerations.

· Project Requirements: The PCB box-build manufacturer you partner with should understand your project requirements.

· Manufacturing capabilities: The box-build manufacturer you partner with should have the means to handle the project.

· Industry Experience: Industry knowledge and experience are vital before partnering with an EMS box build sercices company to avoid costly production errors, save on costs, and improve production quality.

· Supply Chain Efficiency: Component sourcing is an intricate process with many hiccups in the supply chain. You need a box-build manufacturer that understands how to navigate them.

· Regulatory Compliance: Complying with the existing regulations benefits the EMS company and ensures the product's quality and safety. The easiest way to confirm this is to ask the EMS company.

· Quality Management: Quality control is an essential process in box build assembly. The box build assembly manufacturer should be able to explain its quality management protocols.

· Flexibility of Scalability: An electronics box build partner should be adaptable enough. They should be able to scale up or down, depending on whether there is a sharp demand surge or drop.

Judging by the complexity of choosing box-build assembly services, you can have a seamless experience by going with PCBasic. PCBasic is a leading PCB assembly manufacturer, providing comprehensive one-stop solutions that cover everything from PCB design and production to full-scale manufacturing services.

The reliance on box build assembly is massive across various sectors. However, it's essential first to understand how the process works and partner with the right box-build company, and that's where we come in.

At PCBasic, we handle everything from product design to quality control and packaging to ensure a more streamlined box-build process. Contact us today to share your box build needs; we'll gladly help you.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.