Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is turnkey PCB assembly?

Complex situations require innovative solutions in the current world where we work and live in hybrid or remote states. In this article, we will cover the subject of turnkey PCB assembly. We will explain what turnkey assembly services are and what alternatives there are for turnkey PCB assembly services.

Once you master the concept of turnkey PCB assembly, you’ll be able to produce better projects at lower risk. At the end of this article, you’ll be able to choose the right turnkey PCB assembly supplier for your project. You will also know which china’s PCB turnkey assembly manufacturer provides the best service and support for such needs. All this while reducing costs and ensuring your customers are happy with the results.

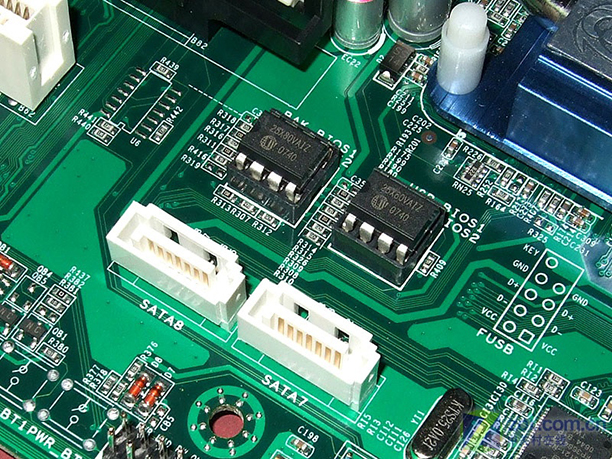

Turnkey PCB assembly is the idea of producing a PCBA project from design to finished product. PCB turnkey assembly involves the following steps:

As we can see, the turnkey custom pcb assembly service includes everything from the beginning to the end. Not knowing such a service is available, customers often choose to produce and purchase components from different suppliers and manufacturers.

This can often lead to tremendous faults and miscommunication between the parties involved. To solve the issue, a turnkey PCB assembly service came into existence. By enabling customers to produce the entire project in one place – we can reduce the risk. Additionally, cost and frustration while handling communication with multiple manufacturers and service providers can be reduced as well.

If a company decides to consider other ways than full turnkey PCB assembly, There is a way. In such a case, the company will need to handle each of these steps on its own:

Diverse the PCB assembly line instead of using a full turnkey PCB assembly method could be risky.

By choosing a turnkey PCB, companies can discard all the disadvantages mentioned above and pay more attention to the product and the customers.

It’s not always black and white. Often, there are points in between to be chosen from. That’s the case with Hybrid turnkey PCBA, where the company can use a turnkey PCBA assembly to produce their entire product. The testing and packaging, however, will be handled by the client’s side.

Normally, there is no right or wrong. These decisions depend on each company, product, budget, and supply chain. Full turnkey PCB assembly, however, will often involve the entire thing. The product needs all the requirements to reach the customer’s doorway.

Nevertheless, it’s always a good idea to consult a trusted turnkey PCB assembly provider to choose what is suitable for your company and product.

The number one advantage of using turnkey PCB assembly is the ease of mind. Companies can focus on what matters the most, ensuring they are prepared for sales, marketing, and distribution channels. There are other advantages involved in using turnkey PCB assembly factories:

Using the PCB assembly turnkey service will save you time. By putting the entire production line in the hands of a trusted, experienced and responsible manufacturer, it’s almost sure the project will be delivered in time.

Budget is a big problem. In mass production, you can avoid counterfeit components, which can be costly. This is especially true during the prototyping stage. By allowing a single manufacturer to produce the entire project, you will certainly receive a good offer that will save you a handful of funds.

Using a turnkey PCB assembly service from a trusted vendor, your project can go on smoothly, knowing each component and part is sourced from a trusted warehouse.

It’s inevitable that during production, especially during the prototyping stage, you might encounter some problems that you’ll need to solve. If having issues is not challenging enough, imagine trying to communicate with 2-3 different suppliers and facilities. All while arranging parts delivery and figuring out what went wrong and who’s a fault for it.

Solving the problem in a single place with a trusted person is the key. And sometimes, it might be all you need. For that reason, a PCB turnkey assembly supplier can be convenient.

If managing a product and bringing it to market is hard enough, imagine the difficulty of working and communicating with multiple factories to produce a single product. By entrusting a turnkey PCB assembly facility, we can eliminate all those worries and management overhead.

Usually, each facility will do well but only on its things. If a project requires multiple parties, someone will need to manage those parties to ensure the project goes smoothly. This is especially true for PCB assembly as it has various aspects such as PCB, components sourcing, community, and testing.

Usually, when using multiple suppliers and manufacturers, each one will be obvious in what they do and what they don’t. By using turnkey PCB assembly, we can ask for customization, modification, or external tests that the manufacturer doesn’t usually include by default.

Because the manufacturer handles the entire product line, they have a sense of ownership and responsibility over it. And often, this will result in the manufacturer agreeing to customization or requirements according to the product demands.

In the end, both the manufacturer and the company inventing the product have the same goal – to ensure the product works well and leaves all the customers happy.

There are many turnkey PCB assembly manufacturers, but it’s almost certain that the best of them are located in Shenzhen, China. China pcb turnkey assembly supplier can ensure consistency and fast delivery as the factories are located in the center of the “silicon valley for hardware”. China PCB turnkey assembly manufacturers have been in the market for years, knowing all the distributors and providers, ensuring all the components are genuine and sourced from trusted suppliers. An excellent example of such a manufacturer would be PCBasic.

At PCBasic, we’ve dedicated years of research and hard work towards mastering turnkey PCB assembly, becoming a well-respected and known china turnkey PCB assembly manufacturer.

By entrusting us to be the turnkey PCB assembly manufacturer for your next project, you can ensure the project stays in good hands. We will handle the entire process, including producing a high-quality PCB, sourcing components from trusted sources, making tests and certifications, and even packaging and assembling the final product.

We always deliver the project on schedule and according to the customer timeline. We can even offer a 24-hour turnkey PCB assembly based on the need. As something that most manufacturers won’t do, this might sound quite surprising.

If you are looking for the best turnkey PCB assembly suppliers, look no more. PCBasic is here to help, and we look forward to our next cooperation.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.