Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > The Best PCBA Service with Advanced SMT Lines from PCBasic

PCBasic SMT PCB assembly began its remarkable journey more than 15 years ago and now is a world leader in high-mix, high-volume and high-speed SMT PCB assembly. They are equipped with 9 SMT production lines which have enabled them to provide fully traceable and reliable assembly services around the globe. Their impressive fully operational SMT production lines allow PCBasic to offer efficient, stable, and traceable production all over the world.

Vertical strategic factory arrangement sets PCBasic apart from other manufacturers. With facilities located both in Shenzhen and Huizhou they created an ecosystem tailored for enhanced rapid-prototyping production along with mass manufacturing. The Quhengda Electronics (Shenzhen) Co., Ltd specializes in small-batch quick-turn services, while their Huizhou factory manages large-volume production runs.

China continues to dominate as the world's PCB producer and PCBasic is among the top contractors offering advanced PCBA services powered by high-performance SMT lines from PCBasic. We became a specialist in the area because we can manufacture high-layer count boards of up to 50 layers, which are suitable for complex and highly dense installations.

PCBA plays an integral role in the electronics industry by adding different components onto bare PCBs transforming them into functional circuits. Our SMT lines offer key advantages: high speed, precise placement, cost-effectiveness, and consistent quality. With PCBasic's modern assembly systems equipped with solder paste dispensers and mounted cameras for inspection, we guarantee accurate placement of components even on small devices.

Unlike many providers who only handle prototype orders with no minimum quantity, PCBasic supports both prototypes and high-volume production without compromising quality. Our flexible and fully adjustable equipment supports a wide range of production needs—offering a distinct advantage over providers focused solely on prototypes.

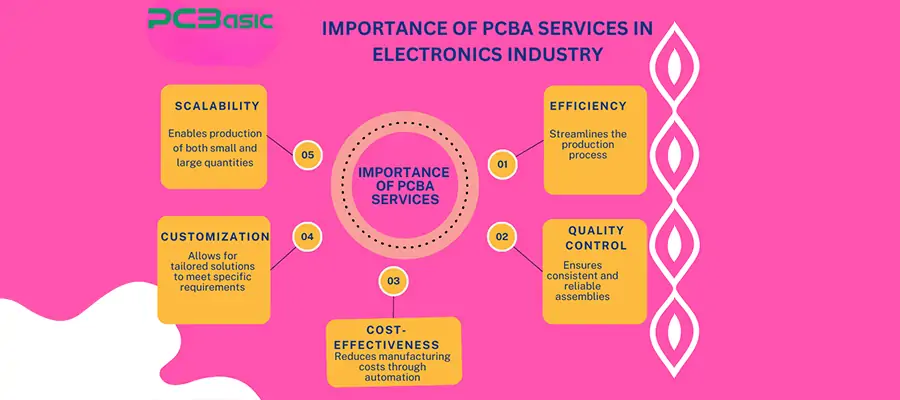

PCBA services play a vital role in the electronics industry for several reasons:

1. Efficiency

PCBA services streamline the production process by combining automatic assembly, accurate component placements and advanced quality control techniques. It reduces production time, reduces errors and ensures frequent product quality.

2. Quality control

PCBA solutions feature repetitive and reliable builds with the help of modern inspection and testing methods and strict quality control according to industrial standards.

3. Cost-effectiveness

Automation in PCBA services helps minimize labor costs, reducing material waste and improving production efficiency, which results in lower manufacturing costs overall.

4. Customization

PCBA services allow customized material selection, layout design, and component allocation to meet complex product requirements.

5. Scalability

PCBA services support small amounts of prototypes and high-volume production, providing flexibility for construction based on market demand.

By taking advantage of advanced PCBA services, companies can grow rapidly for production and competitive prices for high-quality electronic products. This is especially important in today's rapidly developing technology scenario, where the credibility of the market and the product is important to succeed in time.

Surface Mount Technology (SMT) lines form the core base of modern electronics production. Understanding the structure and operation of SMT lines is essential to appreciating how PCBasic delivers superior PCBA solutions. Such automated assembly lines have effectively transformed electronics production since the 1980s, replacing manual through-hole wiring with extremely accurate and efficient processes.

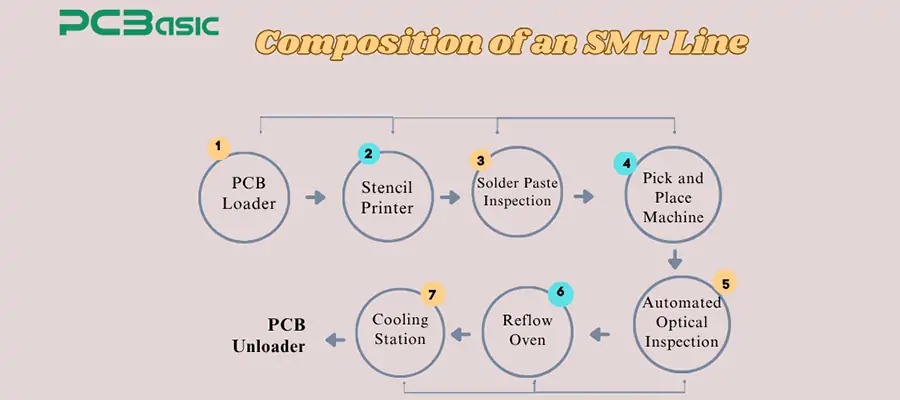

An SMT line consists of a series of interconnected machines working in sequence to assemble electronic components onto PCBs. When I examine a typical SMT assembly line, I find these key equipment pieces working together:

1. PCB Loader

Automatically loads bare PCBs onto the assembly line, providing a continuous board supply.

2. Stencil Printer

Solder paste is correctly deposited by stencil onto exactly targeted PCB pads onto which components are to be mounted.

3. Solder Paste Inspection (SPI)

Examines paste application quality to prevent downstream defects.

4. Pick and Place Machine

The core of the SMT line, robotically picking parts from feeders and depositing them with high precision onto the solder-pasted PCB, with highly sophisticated machines able to place as many as 80,000 parts per hour.

5. Automated Optical Inspection (AOI)

Verifies correct component placement before soldering.

6. Reflow Oven

Gradually heats the board stepwise through a series of temperature zones to melt solder paste, forming permanent electrical connections.

7. Cooling Station

Gradually reduces board temperature to solidify solder joints properly.

8. PCB Unloader

Removes completed boards for final inspection or additional processing.

The process flows continuously as boards move through conveyor systems between stations. Each station performs quality checks, preventing defective boards from progressing further in the line. This integrated approach ensures high production efficiency while maintaining rigorous quality standards.

The relationship between PCBA (Printed Circuit Board Assembly) and SMT (Surface Mount Technology) lines is direct, considering that SMT is a core manufacturing process under PCBA. SMT deals with mounting components on the surface of PCBs without utilizing through-holes, thus facilitating higher component density and allowing components to be mounted on both sides of the PCB.

Effective mass production of PCBAs is based on sophisticated SMT lines that provide high quality via rigorous testing and inspection. For example, PCBasic's use of cutting-edge SMT machines, including sophisticated pick-and-place machines and reflow machines, guarantees high-quality assembly output.

When selecting a PCBA manufacturer, you should take into account their SMT line capacity since these machines are critical in producing high-quality, reliable electronics while being capable of addressing diverse production requirements.

PCBasic's SMT Lines

At the heart of PCBasic's manufacturing superiority lies our cutting-edge SMT production plant. Constructed with absolute precision and efficiency in mind, our plant operates high-end equipment that delivers stable, high-quality PCBA outputs for multiple applications. PCBasic’s SMT line configuration is among the most advanced in the industry.

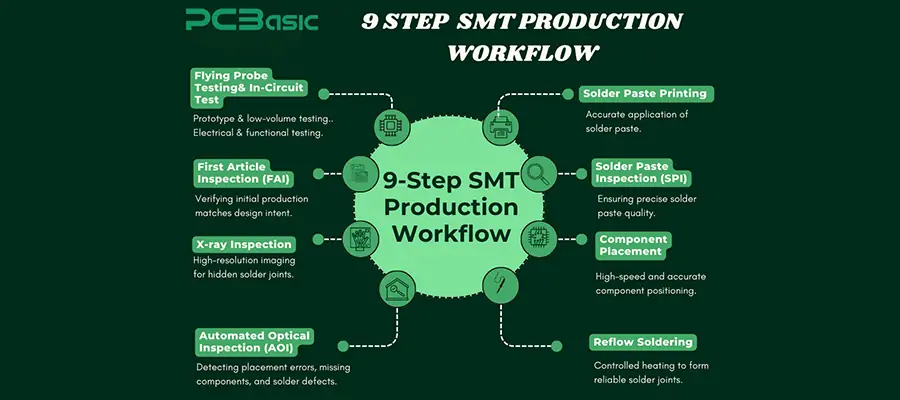

Comprehensive 9-piece SMT Production Line

PCBasic operates a sophisticated 9-piece SMT production line that integrates seamlessly to handle complex mounting with exceptional accuracy. This complete system represents a substantial investment in quality and reliability, setting PCBasic apart from many PCBA service providers. The core components of our SMT line solution work in perfect synchronization:

1. Solder Paste Printing

Our high-precision SMT line machines apply solder paste with meticulous accuracy, ensuring consistent pad coverage across even the most complex boards.

2. Solder Paste Inspection (SPI)

As a critical quality control measure, our SPI technology verifies that solder paste application meets stringent standards before components are placed.

3. Component Placement

PCBasic utilizes high-speed, multi-headed SMT placement machines that position components with extraordinary precision, accommodating a wide range of package sizes.

4. Reflow Soldering

Our advanced reflow ovens feature sophisticated temperature profile control, guaranteeing reliable solder joints that meet international standards.

5. Automated Optical Inspection (AOI)

Integrated AOI systems detect placement errors, missing components, and soldering defects with remarkable accuracy, providing immediate feedback.

6. X-ray Inspection

For components with hidden solder joints, PCBasic employs high-resolution X-ray inspection to ensure perfect connections in BGA and other complex packages.

7. First Article Inspection (FAI)

This crucial validation step confirms that the initial assembly perfectly matches design specifications before proceeding to volume production.

8. Flying Probe Testing

Our flexible testing equipment enables thorough electrical verification of low-volume and prototype assemblies.

9. In-Circuit Testing (ICT) & Functional Circuit Testing (FCT)

These comprehensive test methodologies validate both electrical performance and functional operation.

The integration of nine essential components creates a manufacturing ecosystem that provides great results consistently. Because PCBasic's comprehensive SMT line process covers all critical aspects of production, we achieve remarkable quality metrics at competitive prices.

Our automated line follows a precise sequence: printing, dispensing, placement, curing, reflow soldering, cleaning, and final inspection. These processes set up each assembly for final inspection and comprehensive testing. We have modern traceability systems that capture crucial information pertaining to each board such as the order of operations, soldering parameters alongside inspection results and offer immediate corrective action during verification workflows enabling faultless quality assurance.

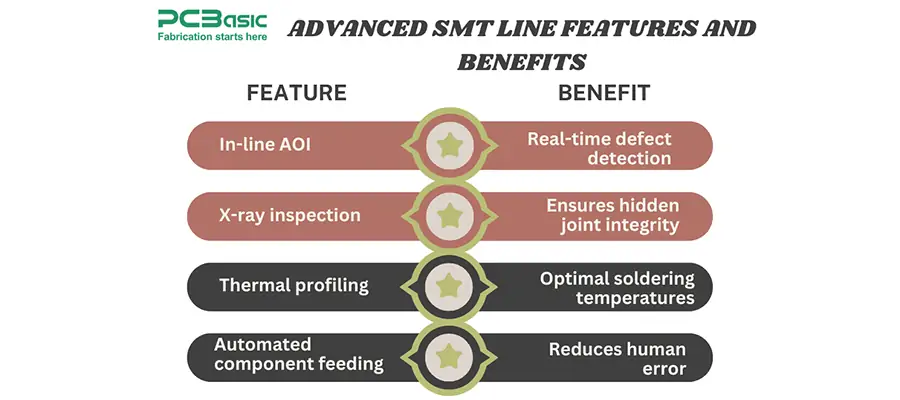

Advanced SMT equipment PCBasic invested in includes special workstations for controlled environments to improve their upkeep as well as environmental control systems which optimize desirable conditions while reducing defects. Consistent production quality is also supplemented by our nine-piece SMT production line from consumer electronics all the way through to medical devices, which is complemented through exceptional PCB assembly, providing unparalleled versatility across many industries.

At PCBasic, we provide advanced SMT production lines along with rigorous quality control procedures, all backed by our industry-leading PCBA (Printed Circuit Board Assembly) services. Our expertise, experienced teams, and customer-first approach make us a trustworthy partner for both prototype development and high-volume production.

Cutting-Edge PCBA Technology

PCBasic's PCBA service stands out in the industry, thanks to its advanced SMT lines. These state-of-the-art production lines ensure high-quality, efficient, and reliable printed circuit board assembly. Our advanced SMT lines offer:

● Precision placement of components

● High-speed production capabilities

● Automated optical inspection (AOI)

● X-ray inspection for hidden solder joints

Quality Assurance and Reliability

At PCBasic, we prioritize quality in every step of the PCBA process. Our advanced SMT lines contribute significantly to this commitment:

Customization and Flexibility

Our advanced SMT lines allow for a high degree of customization, catering to diverse client needs:

● Multiple component sizes and types

● Varying board complexities

● Prototype to high-volume production

● Quick turnaround times

With advanced SMT lines and PCBasic, customers benefit from state-of-the-art technology, strict quality control, and an ideal mix of flexible production skills. This combination ensures that your PCBA projects are completed with the highest quality and efficiency standards.

Ready to experience the cutting-edge PCBA technology firsthand? PCBasic makes reaching out straightforward and efficient. After exploring our capabilities, the next step is connecting directly with our team to bring your electronic projects to life.

Get in Touch with PCBasic

Connecting with our technical experts couldn't be easier. PCBasic maintains two strategic locations in Shenzhen, China's electronics manufacturing hub:

Headquarters: Building E, Jianshi Industrial Park, Huangpu Road 52#, Xinqiao Street, Baoan District, Shenzhen, China

Office Location: 808, Building 1, Yuncheng Intelligent Valley, Hang Cheng Avenue, Bacan District, Shenzhen, China

For technical inquiries about our SMT assembly line capabilities or PCBA manufacturing services, reach our professional consultation team at:

Our team is available during business hours:

● Monday through Friday: 9:00 AM - 6:00 PM (GMT+8)

● Saturday: 9:00 AM - 12:00 PM (GMT+8)

● Closed on Chinese public holidays

Considering our status as a trusted partner for international companies like Google, GM, JABIL, Dell, Samsung, and HP, you can be confident in our ability to handle projects of any scale.

First of all, obtaining a detailed quotation for your PCBA project requires just a few simple steps. PCBasic offers two convenient methods:

1. Online Quote Form: Visit our website to access the instant quote form where you can input your PCB specifications

2. Direct Email Submission: Send your inquiry to JS@pcbasic.com with your project details

To ensure the most accurate and prompt quotation, please include:

● PCB dimensions

● Number of layers

● Component types (SMT, through-hole, or both)

● Special requirements

● Quantity needed

Furthermore, submitting your design files (Gerber or CAD) and BOM (Bill of Materials) will help us analyze your layout and components thoroughly. Once submitted, our team reviews your specifications and prepares a transparent, detailed quote covering fabrication, component sourcing, assembly, testing, and any customization needed. After quote approval, we'll move quickly into production—whether it's a rapid prototype or a large manufacturing run. Not only do we guarantee quality, but our 96.15% on-time delivery record demonstrates our commitment to meeting your timeline requirements.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.